38,360 views ·

360 replies

38k views

360 replies

Load-bearing capacity of aluminum L-beam

Calculating without knowing the load is a bit "pointless"..Huggedugge1 said:

Well... It's an odd application, but as you saw in the video, it works in aluminum for the same pool that I have. But not according to you. From what I understand, you have never designed or built such a solution. But you refer to your extensive competence and long experience so that you didn't need to calculate anything but just go "freehand". Several other people have helped with calculations, and calculatively, most seem to agree on dimensions. Everything fell into a solution that I perceive as good and will look nice.

I can't assess it in any other way, and now it feels like the proposal with an overlaid T-beam is best. Replace the framework to 170 and possibly reinforce with 3 mm stainless steel in the dimensions 170*45 on every other joist, which we set at 45 cm with a few noggings.

I am humbly grateful for all the help I've received from everyone!

Sure, we know what the material weighs in dry condition and can get some type of estimation of the total weight..

But what does the whole structure weigh when it's soaking wet?

10+ years of professional experience in the manufacturing of free-hanging structures (with support points at the ends) exposed to both static and dynamic load, a current occupation in designing such structures, and an ongoing education in welding/material impact make me see the problematics in the structure differently than most here seem to do..

What I would have wanted is to know "more precisely" what the finished structure will weigh.

Then I could actually give you both a better suggestion on the dimension of the components and even a reasonable instruction on the manufacturing process to achieve a resulting deflection of the finished structure of 0 mm.

Because that is what I have worked with before.. Not "allowed deflection X mm" but structures that were straight or nearly straight after X number of years with static load and X number of dynamic load cycles.

That's what your construction will be subjected to with vibrations and weight variations in the structure over the year.

The risk is that you will get a structure that sags more than desired over time if you design and manufacture something with incorrect dimensions..

No, I do not. However, at first glance, I can see more problems in a construction than those who have not worked with such constructions..Bernieberg said:

It's great to have people who, at first glance, can see exactly what the optimal construction looks like to solve a problem. Just congratulations. But the rest of us have to approach problems systematically and evaluate how different variants work. Calculating deflection on a beam isn't very fancy, a fairly basic theory that Galileo came up with and has been used successfully ever since.

Strange? No

I'm not claiming that I have "the optimal solution"

It can't be found without fully knowing the applicable load, and we don't.

The difference is that we have calculated with the estimated own weight of 1500 kg while Träguiden calculates according to the standard for building construction. I don't know much about these standards, but I believe that in addition to own weight, 200 kg load per square meter is also considered or something like that.D Derbyboy said:

Tested calculating a storage roof with the same parameters (440cm mm) and then I got close to your 15mm.

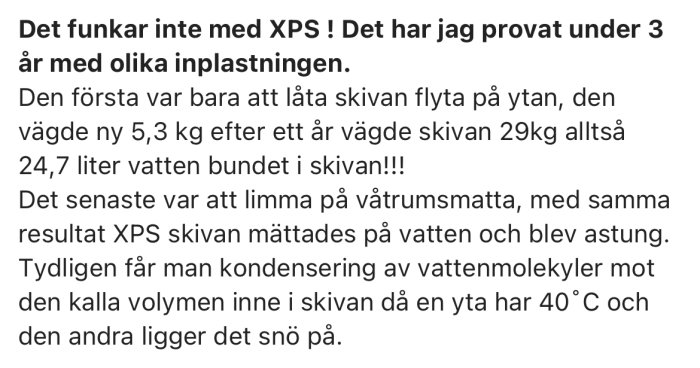

What worries me, however, is that the foam will become waterlogged...

But maybe TS can compensate for that increase with just the metal sheet. TS seems to be a bit of a cowboy

a lot of guesses though

What worries me, however, is that the foam will become waterlogged...

But maybe TS can compensate for that increase with just the metal sheet. TS seems to be a bit of a cowboy

a lot of guesses though

Yes, of course, a reasonable estimate of the load is necessary for calculations. But it would also be required for your professional judgments based on experience?Violina said:

Calculating without knowing the load is somewhat "pointless"..

Sure, we know what the material weighs when dry and can get some kind of estimate of the total weight..

But what does the entire construction weigh when it's soaking wet?

10+ years of professional experience in manufacturing free-hanging constructions (with support points at the ends) exposed to both static and dynamic loading, a current occupation in designing such structures, and also ongoing education in the field of welding/material impact allow me to see the problem in the construction in a different way than most here seem to do..

What I would have wanted is to know "more precisely" what the finished construction will weigh

Then I could actually give you both a better suggestion on the dimension of the material involved and even a reasonable instruction on the method of manufacture to achieve a resulting deflection in the finished construction of 0 mm.

Because that's what I've worked with before.. Not "allowed deflection X mm" but structures that were straight or nearly perfectly straight after X number of years with static loading and X number of dynamic load cycles.

That's what your structure will be subjected to due to swings and weight variations in the construction over the year.

The risk is that you get a structure that sags more than desired over time if you design and manufacture something with incorrect dimensions..

I also have some experience in calculating things that have deflection requirements… However, rarely on buildings, and there are a few other resources available to those who manufacture. But I am more than open to opinions on what works to manufacture, accustomed to such discussions daily. But I don't like when someone dismisses well-established theory in favor of their intuition.

But it is actually possible... to paint a worst-case scenario.Violina said:

If all the EPS were to fill with water after a while, then the weight would be the same as the volume. So, 1 dm3 EPS = 1 kg.

How much does a wet plank weigh?

Assume that 4 people at 75 kg each go up on the roof

and so on, and so on

TS will use sheet metal in the winter, well then we can disregard snow.

I think it's reasonable to assume that insulation that doesn't retain water is chosen, such as that used for floating docks. It's a prerequisite for it to work with a reasonable construction. If the current insulation material does not meet this requirement, it must be replaced.D Derbyboy said:

I only see one concern with TS assuming that his construction weighs 1400 kg but that it could very well weigh 5-6 times more in reality.

Calculating what the dry joists and decking weigh is no problem, but what do soaking wet joists weigh after 5-10 years? Reasonably, a well-saturated somewhat aged joist should weigh more than a new soaking wet joist.

Calculating what the dry joists and decking weigh is no problem, but what do soaking wet joists weigh after 5-10 years? Reasonably, a well-saturated somewhat aged joist should weigh more than a new soaking wet joist.

Yes, the correct order is to first determine the weight of the decking and insulation in its worst condition. Then decide how the transverse joist should be chosen so that you also get the weight from it. And finally, the beam on the long side.

The weight information requested should be obtainable by TS through an on-site field study.

Remove a piece of EPS and weigh it?

Remove a piece of the framing and weigh it?

I might, as an advocate for orderliness, place both the piece of framing and the insulation in a water bath for a few days before using the scale.

The nightmare must be designing and constructing a structure for a load of 1500 kg, only to find out that the structure in its worst case weighs 8000 kg. Adding to that, the structure could certainly land at 50-60kkr.

Remove a piece of EPS and weigh it?

Remove a piece of the framing and weigh it?

I might, as an advocate for orderliness, place both the piece of framing and the insulation in a water bath for a few days before using the scale.

The nightmare must be designing and constructing a structure for a load of 1500 kg, only to find out that the structure in its worst case weighs 8000 kg. Adding to that, the structure could certainly land at 50-60kkr.

Last edited:

No, I will not use sheet metal in the winter. We hardly get snow here in Kungsbacka. And in the worst case, I guess I can brush off the deck. For me here, it's a non-issue.D Derbyboy said:But it is actually possible….to paint a worst-case scenario

if all EPS were to fill with water after a while, then the weight would be the same as the volume. So 1 dm3 EPS = 1 kg.

wet plank, what does it weigh?

count on 4 people at 75 kg who go up on the roof

etc etc

TS will use sheet metal in the winter, well then we can subtract the snow.