38,357 views ·

360 replies

38k views

360 replies

Load-bearing capacity of aluminum L-beam

We've already used it for a summer, and there was no difference in weight on the styrofoam. If you disregard the algae... on the other hand, if they weigh too much, they will collapse into the pool.D Derbyboy said:I only see one concern with assuming that the construction weighs 1400 kg when it might actually weigh 5-6 times more in reality.

Adding up what the dry joists and decking weigh is not a problem, but what will the soaking wet joists weigh after 5-10 years? Presumably, a well-saturated, slightly aged joist should weigh more than a new soaking wet joist.

When looking at Aqvisdeck or regular pool covers, it feels like it's dinghies and now one has to build a cargo ship.D Derbyboy said:The weight information being asked for should be something the original poster can obtain through an on-site field study.

Remove a piece of EPS and weigh it?

Remove a piece of timber and weigh it?

Possibly, as a lover of order, I would place both the timber piece and the insulation in a water bath for a few days before using the scale.

The nightmare scenario would be to dimension and construct a structure for a load of 1500 kg, only to find out that the structure at its worst weighs 8000 kg. On top of that, the structure might surely end up costing 50-60kkr.

The wood will likely absorb moisture over time but… 50-60ksek is still better than 200Ksek.

Well I have no opinion on how much snow to expect. But you have to choose something and it seems a bit silly to expect none...

Being the true theoretical thinker that I am, I pondered a bit about the banana. I understand that there will be tensile stresses in the longitudinal direction of the weld. Then I assert that the beam will warp in the right direction (which is favorable in the current case) when welding below the cross-section's neutral plane.Violina said:

How much do you think it will warp? Do you have a decent grasp of it in advance or does it "turn out as it turns out"? In the world I inhabit, you can calculate it (possibly bordering on elegant calculations) with a controlled welding process, but how does it work if you were to manufacture?

I have another question that I asked before (apologies if I missed any possible answer): Isn't there a large risk that your upside-down T-beam will collapse at the top due to buckling? That it crumples because it lacks a flange. Or do you think the wooden studs will brace it? I'm not used to calculating buckling (and have tried to avoid the risk when welding my own).Bernieberg said:

As the true theorist I am, I pondered a bit about the banana. I understand that there will be tensile stresses in the longitudinal direction of the weld. Then I claim that the beam will bend in the right direction (the one that is favorable in the current case) when welding below the neutral plane of the cross-section.

How much do you think it will bend? Is it fairly predictable in advance or "does it become what it becomes"? In the world I reside in, it can be calculated (possibly bordering on fancy calculations) with a controlled welding process, but how does it work if you were to manufacture?

I tried to address that in post #227. If unsure, you can take a closer look, and if needed, place stiffeners in a few spots. Then you'll have to sacrifice the stiffness contribution from the inner wooden beam since it will have to be sectioned. But, as mentioned, I don't think it's necessary.E Erik Lindroos said:I have another question I asked before (apologies if I missed any response): Isn't the risk high that your upside-down T-beam will collapse at the top due to buckling? That it will wrinkle because it lacks a flange. Or are you thinking that the wooden beams will brace it? I'm not used to calculating buckling (and have tried to avoid the risk when welding my own).

I want to emphasize that I don't see this as an ideal solution better than others. But I tried to think about making the beam blend in and that it would be easy to assemble with the wooden construction, and I got a bit stuck on it. The possible problems might be the manufacturing and potentially the cost if it becomes very specialized. But it might be easier if you abandon stainless steel, which I realize is probably reasonable to do. It might also be possible to find a ready-made beam with suitable dimensions that could work in such a construction.

Suspected I missed a reply... Thanks!Bernieberg said:

Tried to answer that in post #227. If you're unsure, you can take a closer look at it, and if needed, add reinforcing stiffeners in a few places. Then you'd have to sacrifice the contribution to stiffness from the internal wooden beam as it would need to be cut up. But as I said, I don't think it's necessary.

I want to point out that I don't see this as an ideal solution better than others. But I tried to consider getting the beam to blend in and to be easy to assemble with the wooden structure, and I leaned towards that. It's probably the manufacturing and possibly the price if it gets very custom that could be potential issues. But it might be easier if you abandon stainless steel, which I realize might be reasonable to do. Perhaps it's also possible to find a finished beam with decent dimensions that could work in such a construction.

No, it's important not to get too attached to your favorites.

Thanks for an enlightening discussion and hope everything ends in something sensible for TS.

Precisely, you are a theorist.Bernieberg said:

As the true theorist I am, I pondered a bit on the banana. I understand that there will be tensile stresses in the longitudinal direction of the weld. I then claim that the beam will deform in the right direction (which is favorable in the current case) when welding below the cross-section's neutral plane.

How much do you think it will deform? Is there a decent estimate beforehand or does “it become what it becomes”? In the world I inhabit, you can calculate it (possibly on the verge of fancy calculations) with a controlled welding process, but how does it work if you were to manufacture?

I have both theoretical AND practical experience..

(A welder for about 15 years, trained in the mechanical engineering field, and now pursuing an advanced education in welding/material impact)

I CAN back up about 95% of my positions and gut feelings even with theory and calculations, BUT as my mentor in mechanics/strength/calculations told me during my education, "You have something that most in this industry unfortunately lack, and that is the ability to immediately see and assess the reasonableness in constructions and load cases."

Why spend time on calculations when you don't know the load?

I can without problem calculate and then devise a plan for executing the work to achieve a final construction without resulting deflection but NOT WITHOUT KNOWING THE LOAD.

For this case, it is so uncertain that I don't see the point; rather, it becomes a case of "as over-dimensioned as allowed just to be on the safe side" type of situation.

And regarding the stainless steel construction, no, if you've never worked with welding stainless, I can understand that one wouldn't grasp how it behaves when it gets hot and then cools down.

Linear expansion coefficient is a bitch

Yes, all that sounds great as mentioned. But we've already talked about not being able to make a final calculation without knowing the loads but getting quite far with estimates. In the work of designing, it reasonably includes analyzing which loads are present and figuring out what needs to be considered.Violina said:

Precis, du är teoretiker.

Jag har både teoretisk AND practical experience.

(Welder for about 15 years, education in the mechanical engineering field and currently studying an advanced course in welding/material impact)

I CAN back about 95% of my positions and gut feelings even with theory and calculations, BUT as my mentor in mechanics/strength/calculations told me during my education, "You have something that most in this industry unfortunately lack, and that is the ability to directly see and assess the feasibility of constructions and load cases."

Why spend time on calculations when you don't know the load?

I can easily calculate and then set up a plan for the execution of the work to achieve a final construction without resulting deflection BUT NOT WITHOUT KNOWING THE LOAD.

For this case, it is so uncertain that I don't see the point; it becomes a case of "as over-dimensioned as allowed, just to be on the safe side," type.

And regarding the stainless steel construction, no, if you've never worked with welding stainless steel, I can understand not grasping how it behaves when it gets hot and then cools down.

The coefficient of linear expansion is a bitch

I didn't say I don't understand the thermal expansion, on the contrary, I understand it perfectly and opposed which direction you said the banana would go. So please answer that question instead of highlighting all you can.

That was something we considered from the start. Among other things, we had building plastic under the deck, but we removed it. It created ponds in every section when it rained.Bernieberg said:

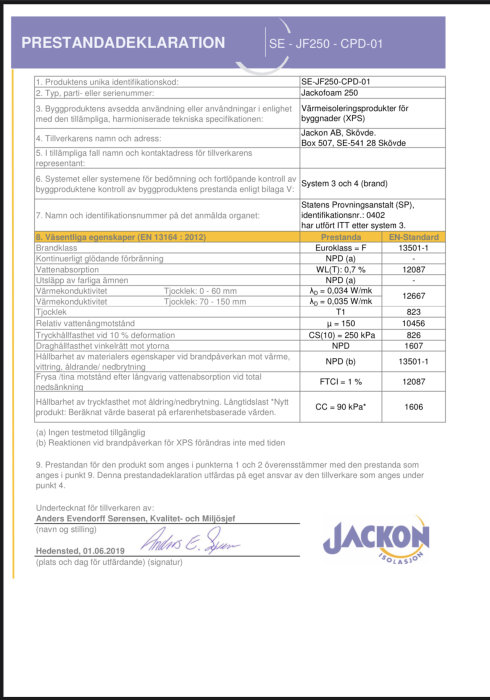

The question is what the difference is between your XPS and the one in the thread @Derbyboy linked to where it absorbed an incredible amount? I quickly googled and ended up in a study where XPS in the ground absorbed 20 vol%.Huggedugge1 said:

I was apparently perceived as arrogant in a comment for which I apologized. Very, very thankful for all the posts and all the help I've received.Violina said:

Exactly, you are a theorist.

I have both theoretical AND practical experience.

(Welder for about 15 years, education in the mechanical engineering field and now studying an advanced course in welding/material impact)

I CAN back up about 95% of my positions and gut feelings also with theory and calculations, BUT as my mentor in mechanics/strength/calculations told me during my education "You have something that most people in this industry unfortunately lack, and that is the ability to immediately see and assess the reasonableness in constructions and load cases"

Why spend time on calculations when you don't know the load?

I can easily calculate and then set up a plan for the execution of work to get a final construction without resulting deflection, but NOT WITHOUT KNOWING THE LOAD.

For this case, it is so uncertain that I don't see the point, instead, it becomes a case of "as over-dimensioned as allowed just to be on the safe side".

And regarding the stainless steel construction, no, if you've never worked on welding stainless steel, I can understand that you don't comprehend how it behaves when it gets hot and then cools down.

The coefficient of linear expansion is a bitch

But friend, tone yourself down a bit. I have had the privilege of working with incredibly brilliant people on a world level for many years. All have been fantastically humble and helpful. Just like many in this forum/thread.

Even you can undoubtedly come up with a few bad ideas and suggestions. Like Aqvisdeck that you declared idiotic. Shouldn't your gut feeling have picked up on that? Earlier you commented that you could intuitively put together the solution and now you're asking for more facts. Since you additionally don't like the pool, I don't get why you're setting records in comments? Doesn't come across as a good personal trait. Unfortunately. Just Messerschmidt attitude. Sorry. I hope I'm wrong if we were to meet IRL.

No idea, but that's how I perceive it. It is sold as low moisture absorbing.Bernieberg said: