38,397 views ·

360 replies

38k views

360 replies

Load-bearing capacity of aluminum L-beam

Excuse me, but what is livförstyvning?Bernieberg said:

Tried to answer that in post #227. If uncertain, you can take a closer look, and if needed, you can add livförstyvningar (stiffeners) at a few places. Then you have to sacrifice the stiffness contribution from the inner wooden beam as it will have to be cut up. But, as mentioned, I don't think it's necessary.

I want to emphasize that I don't see this as a dream solution better than others. But I tried to think about making the beam blend in and be easy to integrate with the wooden construction, and I got a bit stuck on this idea. The potential problems could be manufacturing and possible cost if there are many customizations required. But it might be easier if one abandons stainless steel, which I realize is probably reasonable to do. Perhaps it's also possible to find a ready-made beam with suitable dimensions that could work in such a construction.

I think your solution is exactly what I hope will solve my problem! Thank you so much!

Read some of it in the beginning, but I haven't kept up with the whole thread. Isn't it "just" about getting the cover to handle the end of the opening movement? Snow load shouldn't be a problem if it's only operated when cleared.

A couple of meter-high, removable corner posts and a wire winch like a boat trailer winch that tightens the long side via a loop in the middle of the span. Have such solutions been suggested? Setting up the posts with possibly diagonal bracing and cranking a few turns isn't as easy as having it work entirely passively, but since the issue hasn't been resolved in 300 posts, I thought I'd add how I would have solved it.

A couple of meter-high, removable corner posts and a wire winch like a boat trailer winch that tightens the long side via a loop in the middle of the span. Have such solutions been suggested? Setting up the posts with possibly diagonal bracing and cranking a few turns isn't as easy as having it work entirely passively, but since the issue hasn't been resolved in 300 posts, I thought I'd add how I would have solved it.

Was thinking along similar lines from the start. But want a motorized control. It becomes impractical if you have to go out and pull on winches and remove posts. Then the pool doesn't get used.Karrock said:

Read a bit at the beginning, but haven't kept up with the whole thread. Isn't it "just" about getting the cover to withstand the end of the opening movement? Snow load shouldn't be a problem if it's only maneuvered when shoveled.

A couple of meter-high, removable corner posts and a wire mechanism like a boat trailer winch that tensions the long side via a loop in the middle of the span. Have such solutions been suggested? Setting up the posts with possible diagonal braces and cranking a few turns is, of course, not as easy as having it work completely passively, but since the question hasn't been resolved in 300 posts, I thought I'd add how I would at least solve it.

Livförstyvning or livavstyvning are plates that are welded in to support the web laterally. Kind of like triangles that connect the web and the flange. If parts being compressed are too slender, they can buckle, snap, instead of taking on the compression load. It's often illustrated by standing a ruler or something vertically and pressing on it; at a certain load, it buckles and bends a lot.Huggedugge1 said:

Aha! Kind of like boxing in an IPE beam. Thanks for the answer!Bernieberg said:

Web stiffening or web reinforcement consists of plates welded in to support the web laterally. Like triangles that connect the web and the flange. If parts being compressed are too slender, they can buckle, snap, instead of absorbing compressive load. Usually illustrated by standing a ruler or something on edge and pressing on it, at a certain load it snaps out and bends significantly.

- It says low moisture absorption for the board you linked to,Huggedugge1 said:

- you don't experience that the boards you mounted have become heavier

- I linked to a post where polystyrene was used on a warm spa in the winter. Maybe that's different.

You have quite clear indications that the board doesn't get much heavier. If you want to be sure, you can always call Jackon and ask and/or do a test on a board. Minimal effort in the grand scheme of things.

You know what I would have done….

Huggedugge1 said:

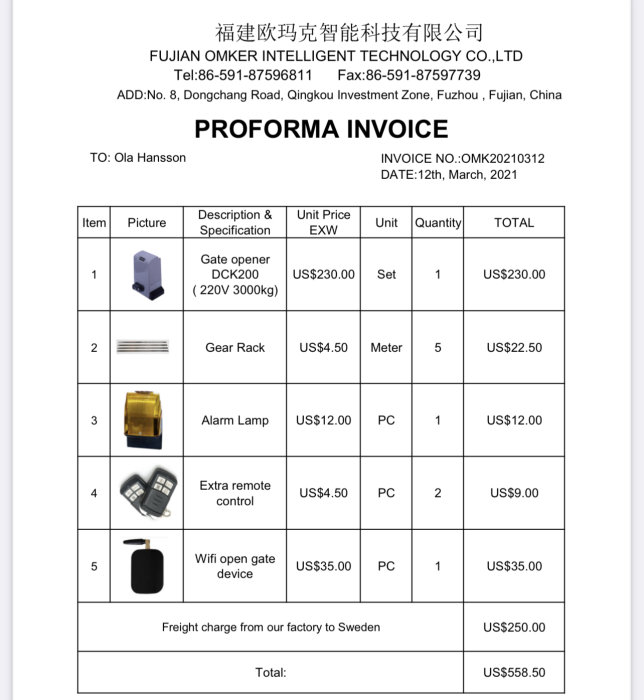

Can you link to a motor, I'm not getting any sensible search results for "rullgrindsnotor".

I assume it is completely invisible, no visible cables or the like.

It is a gear wheel attached to the engine that runs in a rack attached to the pool deck.D Derbyboy said:

Can't find a link to it now but bought it via Alibaba.

It's located at the short end facing the fence. Quite small, so it’s not immediately visible. Plus, I'm not using the Wi-Fi modules but have installed a Sonoff solution that I use for lighting indoors and outdoors, bar, etc.D Derbyboy said:

Here is a weaker alternative that Amazon sells. Important to get a motor that handles as much as possible and is not programmed in prom to close after X number of seconds. Otherwise, it is a simple solution.D Derbyboy said:

CO-Z Automatic Sliding Gate Opener with 2 Remote Controls, Electric Rolling Driveway Slide Gate Motor, Complete Gate Operator Hardware Security System Kit for Sliding Gate Up to 40 Feet https://www.amazon.com/dp/B0197V3OD2/ref=cm_sw_r_cp_api_glc_i_85AS0QBXFECSPENFVG9J