95,556 views ·

172 replies

96k views

172 replies

Your worst example of runaway building material prices

S

SueCia

Electronics enthusiast

· Dalarna

· 5 298 posts

SueCia

Electronics enthusiast

- Dalarna

- 5,298 posts

Can we end up in a situation where more and more sawmills (I assume many sawmills started up because of the high price) are sitting on enormous inventories and prices fall much lower than in 2020? It must be a risk for these sawmills to hold too large inventories?

As far as I know, sawmills don't have stockpiles. They usually saw directly for the customer.S SueCia said:

I'm talking about Hjortkvarns Timber, which reportedly has a turnover of more than a quarter of a billion and is fairly large in Närke/Östergötland.F Fluxor said:

Holmen's small sawmill in Linghem in central Östergötland likely also uses air drying, but that's not something I've seen with my own eyes this year. You might consider Linghem a local sawmill; they only had 75,000m3 when Holmen bought them about 5 years ago.

I'm happy if I manage to saw 500 logs in a year. Sometimes it's just 50; that's what I call small-scale.

S

swirve

Electronics enthusiast

· Östergötland

· 1 472 posts

swirve

Electronics enthusiast

- Östergötland

- 1,472 posts

Do you saw for yourself, or do you sell to others as well? I'm possibly planning to build a guest cabin sometime and thought about finding some local sawmill in Östergötland that can saw a bit of mixed lumber, not necessarily finely sawn, to match the other old buildings.F fribygg said:I am talking about Hjortkvarns Timber which reportedly has a turnover of more than a quarter of a billion and is fairly large in Närke/Östergötland.

Holmen's small sawmill in Linghem in central Östergötland probably also has air-drying, but it's nothing I've seen with my own eyes this year. Linghem you might consider a village sawmill, they only had 75,000m3 when Holmen bought them about 5 years ago.

Personally, I'm happy if I manage to saw 500 logs a year; sometimes it's just 50. That's what I call small-scale.

They can hardly air-dry 75,000m³ sawn per year? That process must take an eternity.F fribygg said:I'm talking about Hjortkvarns Timber, which reportedly turns over more than a quarter of a billion and is reasonably large in Närke/Östergötland.

Holmen's small sawmill in Linghem in central Östergötland probably also does air drying, but it's not something I've seen with my own eyes this year. You might consider Linghem a village sawmill; they only had 75,000m3 when Holmen bought them about 5 years ago.

Personally, I'm happy if I manage to saw 500 logs a year. Sometimes it's just 50. That's what I call small-scale.

And yes, it's a small sawmill in my eyes.

There was an article in Corren about Holmen - https://corren.se/artikel/skenande-priser-gor-holmens-jattesatsningar-till-succ/jv9n9o1lF Fluxor said:

Soaring prices make Holmen's giant investments a success

Holmen Timber invested at the right time. Something they are getting unusually well paid for. "The price increases are the largest we've seen in 100 years. One might not need to say more than that," says CEO Johan Padel.

Johan Padel, CEO of Holmen Timber, believes in a bright future with higher timber prices. "But it won't be at the levels they are at now."

Photo: Holmen

It is the last workday before the vacation for Holmen Timber's CEO Johan Padel, and it has been perhaps the most unusual year ever in the sawn wood industry. Especially in the US market, where price levels quadrupled and made the futures price for 1,000 board feet of sawn wood exceed $1,800 at its highest before it declined again.

It has been the wild west, but in a successful way for Holmen's sawmills.

– It's the American market that has driven up the prices of sawn timber. It's extreme in the USA, says Johan Padel.

Holmen's sawmills, and especially the Braviken facility in Norrköping, entered the boom with investments at the right time.

An impregnation plant for 55 million SEK.

170 million was invested in a new sorting plant and two drying chambers.

And Holmen also acquired a sawmill in Linghem, which is the group's fifth.

Braviken is the latest newly constructed sawmill of the group's in Norrköping, which has seen further investments.

Then came the pandemic which changed consumer behavior patterns, allowing Braviken's sawmill to step in with increased capacity.

– It has meant a lot. It might be hard to put numbers on it. What's interesting is that we've seen the same pattern and movement in the USA as here in Sweden. Perhaps even more there. That many have done a lot of renovations to their homes during the pandemic year. Meanwhile, construction continued at a normal pace, along with a DIY trend of unprecedented levels. This drove up prices more than we dared to expect, says Johan Padel.

In the European market and in Sweden, it's more long-term on quarterly and semi-annual contracts. This makes the movements less erratic, or slower, in the timber market. The price level for timber purchased in Sweden is at 2018 levels, while seeing record sales.

– Positive after a very long period of poor profitability. Even in Sweden, we've had volatile – fluctuating – prices going up and down. Many lean years balanced by a good year. Profitability is needed in the industry to be able to invest and be profitable. However, I also think that the price increase we've seen in the past six months is quite excessive for it to be called a healthy development.

Is it a bubble?

– There are similarities to a bubble. But it is strong demand that has driven up the levels. Wood is timely as an environmentally friendly, good, and sustainable building material. However, I think there has been an overreaction to prices, says Johan Padel.

Braviken sawmill started in 2011 and has, with its location, become an important point in Holmen's production of sawn timber. Of 550,000 cubic meters of lumber, 350,000 are exported. 200,000 cubic meters of lumber remain in Sweden, mainly in Mälardalen and Östergötland, shortening transport distances.

– The ambition is for Braviken to become Sweden's largest sawmill, and we are basically there today. It is an automated operation. We don’t foresee any new recruitments, but it ensures that Braviken is a facility for the future, says Johan Padel.

The CEO believes the price outlook for sawn wood will stabilize.

– It won't be at the levels they are at now, but we assess that it has a bright future.

A historic financial result for 2021?

– I wouldn't dare to say. But the official price increases are the largest we've seen in 100 years. One might not need to say more than that. It was a good first quarter for us, says Johan Padel.

Holmen's five sawmills

Braviken sawmill. From 2011.

Products: timber for joinery and construction and impregnated timber.

Iggesund sawmill, from 1990.

Products: pine timber for joinery.

Linghem sawmill, from 1950, acquired 2017.

Products: timber for joinery and construction.

Bygdsiljum sawmill, from 1960, acquired 2020.

Products: sawn timber, glued timber, KL-timber.

Kroksjön sawmill, from 1920. Part of Holmen 2020.

Products: sawn and planed timber. Processing of construction products, timber bridges, and building components.

Well, they don't keep stock of sawn for that. They make money by selling.E Evian said:There was an article in Corren about Holmen - [link]

Soaring prices turn Holmen's massive investments into success

Holmen Trävaror invested at the right time. Something they are getting unusually well-paid for. "Price increases the largest we've seen in 100 years. One might not need to say more than that," says CEO Johan Padel.

Johan Padel, CEO of Holmen Trävaror, believes in a bright future with higher timber prices. "But it will not be at the levels they are at now."

Photo: Holmen

It is the last working day before the vacation for Holmen Trävaror's CEO Johan Padel, and it has been perhaps the most unusual year ever in the sawn timber industry. Especially in the US market, where price levels quadrupled, making the futures price on 1,000 board feet of sawn timber surpass $1,800 at its peak, before it started to fall again.

It has been wild west, but in a successful way for Holmen's sawmills.

– It is the American market that has driven up prices on sawn timber. It is extreme in the USA, says Johan Padel.

Holmen's sawmills, especially the Braviken facility in Norrköping, entered the upturn with investments at the right time.

An impregnation facility for 55 million SEK.

170 million invested in a new sorting plant and two drying channels.

And Holmen also purchased a sawmill at Linghem, which is the group's fifth.

Braviken is the latest new construction of the group's sawmills in Norrköping, which has been further invested in.

Then came the pandemic, which changed consumer behavior patterns, as Braviken's sawmill could enter with increased capacity.

– It has meant a lot. It is perhaps difficult to put numbers on it. What is interesting is that the same pattern and movement have been seen in the USA as here in Sweden. Perhaps even more so there. That people have renovated a lot on their homes during the pandemic year. Meanwhile, construction has continued at a normal pace, plus a home DIY of unprecedented scale. This has driven up prices more than we dared to expect, says Johan Padel.

In the European market and in Sweden, it is more long-term on quarterly and semi-annual contracts. This means that movements are not as jerky, or slower, in the timber market. The price level of the timber purchased in Sweden is at the 2018 level, while record highs in sales are achieved.

– Positive after a very long time of meager profitability. Even in Sweden, we have had volatile – fluctuating – prices that go up and down. Many lean years that are offset by some good years. Profitability is needed in the industry to be able to invest and have profitability. Then I can also think that the price increase we have seen in the past six months is too strong to be called a healthy development.

Is it a bubble?

– There are similarities to a bubble. But it is a substantial demand that has driven up the levels. Wood is right in time as an environmentally friendly, good, and sustainable building material. But there has been an overreaction to prices, I think, says Johan Padel.

Braviken sawmill was started in 2011, and with its location, it has become an important point in Holmen's production of sawn timber. Of 550,000 cubic meters of timber, 350,000 are sold for export. 200,000 cubic meters of timber remain in Sweden, primarily in Mälardalen and Östergötland, which shortens the transports.

– The ambition is for Braviken to become Sweden's largest sawmill, and we are essentially there today. It is an automated operation. That there will be some new recruitments, we do not see that, but on the other hand, it ensures that Braviken is a future facility, says Johan Padel.

The CEO believes that the price trend for sawn timber will stabilize.

– It will not be at the levels they are at now, but we estimate that it has a bright future.

A historic financial statement for 2021?

– I dare not say. But the official price increases are the largest we have seen in 100 years. One might not need to say more than that. It was a good first quarter for us, says Johan Padel.

Holmen's five sawmills

Braviken sawmill. From 2011.

Products: wood products for joinery and construction as well as impregnated wood products.

Iggesund sawmill, from 1990.

Products: pine wood products for joinery.

Linghem sawmill, from 1950, purchased 2017.

Products: wood products for joinery and construction.

Bygdsiljum sawmill, from 1960, purchased 2020.

Products: sawn wood products, glulam, CLT.

Kroksjön sawmill, from 1920. Part of Holmen 2020.

Products: sawn and planed wood products. Processing of building products, wood bridges, and building components.

There is drying time which Holmen had built two channels to speed up. I don't know how Hjortkvarn does it, but there are always bundles that you can see from the road.F Fluxor said:

But otherwise, I don't think they hold onto bundles for better times either; they probably send them off as soon as they can!

Anything that is dried and higher quality than vrak is usually covered on five sides. What you can see that is not covered at all is what is supposed to go into the dryer.E Evian said:

The drying time is probably just as long if I have 7.5m3 as when Linghem has 75,000m3, however, it is space-consuming and ties up capital to have inventory.F Fluxor said:

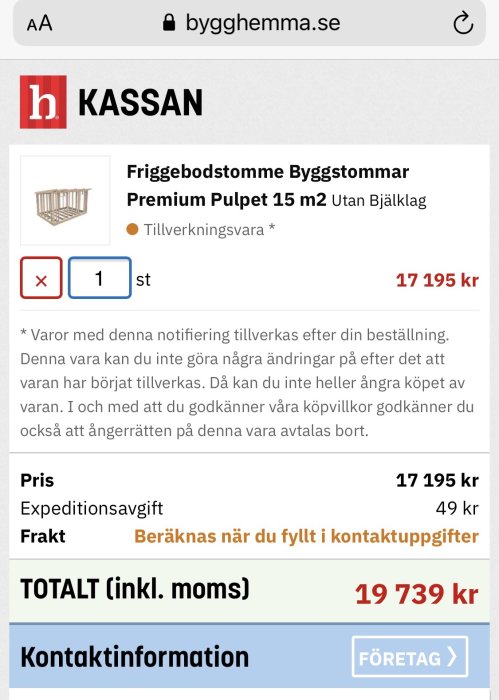

The Friggebod I planned to buy went from 32,000 to 52,000 overnight. So, like, crazy expensive!Direktör Modig said:

Sandbox for the kids, 1200 SEK for 6 pieces 34x145 3.6 meters, there was no building summer this year. I was reluctant to take out an extra mortgage to replace fascia boards.

Talked to someone at Byggmax today. They buy as much OSB as they can get their hands on. Everything runs out the same day.

People know when they get a delivery and pick up pallets.

He said there's a crazy demand. 249:- for a 90cm they took.

People know when they get a delivery and pick up pallets.

He said there's a crazy demand. 249:- for a 90cm they took.