155,670 views ·

317 replies

156k views

317 replies

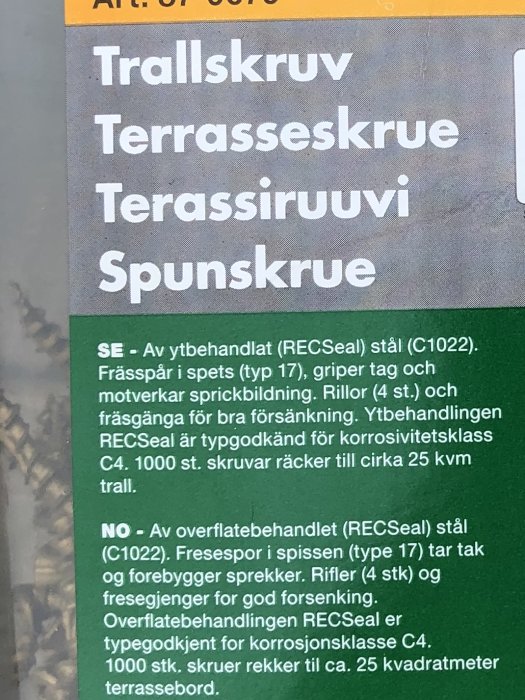

Warning for Biltema's decking screw

Warnings are given for Biltema's and other low-priced brands' self-drilling deck screws, which is justified as they are poor in design and function. To be self-drilling for crack-free assembly, the screw must have a long drilling tip with a sharp edge and a thread with a sharp toothed edge to easily cut through the wood. Low-priced brands do not have this but are poor copies with dull edges without teeth, which means that the screw must be pressed through the wood with great force. In dense wood, the force becomes too great and the screw breaks, while in poor-quality wood, the wood cracks. There are two solutions: pre-drill with a 3 mm bit or buy expensive quality screws with a sharp toothed edge. Biltema's screws hold up excellently with pre-drilling. Pre-drilling always gives a very good crack-free result for all screw brands and is a must for stainless acid-proof screws.J jesper_t said:

I have received many different tips in this thread. I should have pre-drilled, I should have hand-screwed, and above all, I should have understood that you can't use these screws for what I used them for. The problem, as I see it, is quite simple, these screws do not hold up to what Biltema promises. “Deck screw for outdoor use, C4-class, milling grooves prevent cracking, ridges and milling thread for good countersinking” This is a lie and pure nonsense! These screws are completely worthless, hence my warning through this thread.

Absolutely right, Biltema's C4 deck screw does not deliver on what can be considered promised regarding quality. It says on the can milling thread, butJ Johan byggare said:I have received many different tips in this thread. I should have pre-drilled, I should have hand-screwed, and above all, I should have understood that these screws cannot be used for what I had them for. The problem as I see it is quite simple, these screws do not meet what Biltema promises. "Deck screw for outdoor use, C4 class, countersink groove prevents cracking, ridges and milling thread for good countersinking." This is a lie and pure nonsense! These screws are completely worthless, hence my warning through this thread.

the screw lacks milling thread in its true meaning to mill grooves.

Milling thread is sharp saw-toothing on the screw edge, a milling head on the other hand provides good/easy countersinking.

The absence of milling thread gives high resistance to screwing. The milling groove at the tip is too weak and not sharp enough, and does not drill sufficiently well. The screw material lacks sufficient toughness and breaks too easily, probably not the right material composition. The screw design is poor and causes it to break. Overall, the screw's design requires too much torque for the material, especially in pine deck. It does hold with pre-drilled holes, however, this is not indicated in the product declaration. Avoid Biltema's C4 deck screw, I don't know what happens with the rust protection over time. A deck should last 20-30 years, so don't skimp on quality.Unbelievable that people even buy screws at Biltema without guarantees that they can handle what they should.

Some things are good at Biltema, some are pure rubbish.

All that glitters is not gold

Yes, I shop at Biltema. However, I am selective about what I buy.

Some things are good at Biltema, some are pure rubbish.

All that glitters is not gold

Yes, I shop at Biltema. However, I am selective about what I buy.

It also depends on the wood you are screwing into. If you use the same thickness screw to screw 145x34 mm and 22x120 mm, I understand why some have problems. A 4.2 mm screw is simply not designed to withstand such large forces. I don't understand why people don't use standard construction screws instead, because you probably use them for all other wood that isn't nailed, right? A 4.2 mm decking screw can hardly withstand the powerful screwdrivers available today, so the damage starts as soon as it's installedJ Johan byggare said:I just want to share a warning about Biltema's decking screws, see pictures below. I laid 20 square meters of decking in the spring of 2018, the first 15 with screws of an unknown brand and about 5 square meters with Biltema's screws.

The unknown brand has no problems, but now I note that about 90% of Biltema's screws have simply broken.

It's hard to find worse crap, and I hope not many of you have bought and used the same junk!

[image] [image]

For 34x145, 2 screws of 4.2 x 70-75 should be used, for 22x120, 2 screws of 3.9x 51 should be used; however, 22 mm should not be used as decking and definitely not fast-growing spruce as it will certainly crack. Poor quality wood that becomes expensive. Construction screws have large heads that don't look good on decking floors, but if accepted, a 5 x 70 C4 construction screw is better in 34x145. I agree that the biggest problem with Biltema's decking screws is handling errors due to improperly set screwdrivers and incorrect screw technique. I have now assisted in building a deck with Biltema C4 without issues in 28 x120, but it's yet to be seen what happens if the screw has to be removed in 10 years. However, I only pre-drilled at end grain. With the wrong technique, there is a high risk that it will break as the material quality can't withstand high torque.S Sveis said:Depends on the type of wood as well. If you use the same thickness screw for 145x34 mm and 22x120 mm, it's understandable that some have issues. A 4.2 mm screw simply isn't designed to withstand such large forces. I don't understand why people don't use standard construction screws instead, since you probably use those on all other wood that's not nailed? A 4.2 mm decking screw can hardly handle the powerful screw machines available today, so the damage starts right when it's being installed

M.Eriksson said:

Was it a screw with a countersunk head or with a flat underside?

If it was countersunk, it's not surprising that it broke as you get an inadequate contact surface. Unfortunately, I've made similar mistakes myself but have now learned how important it is to use the right screw for the right type of job

Well, I disagree with what you write there. A countersunk head holds much better against breaking than one with a flat head. The countersunk one sneaks into the wood; the resistance during screwing increases gradually until it's fully sunk flush with the wood.M.Eriksson said:

With a flat head, you have the same resistance when you drive the screw in until the head meets the wood; then the resistance increases quickly and directly, and you have a much greater risk of breaking it. Compare it to pre-drilling at a hard knot and driving in a screw. If you drive in a countersunk one, it will probably break (unless you've made a proper hole when pre-drilling), but if you drive in one with a flat head, the screw would undoubtedly break unless you practically hand-drive the screw the last part.