13,648 views ·

40 replies

14k views

40 replies

Pull together two decking boards 28mm

Have you considered using träplugg and polyurethane glue? Otherwise, drill a small hole in the handrail and insert a shortened nail to mark where the plug should be. Drill for the plug in the handrail and the lower board and mount the plug in the handrail with glue. Let it dry. Glue in the lower board and contact surface, mount with clamps, and wipe off excess glue with acetone. Guaranteed to hold but of course, hard to dismantle!D Derbyboy said:Hi,

I'm working on a staircase (outdoors) and was planning to use two 28x120mm decking boards as handrails. The top board, the one you hold onto, should be screwed into the underlying board from underneath. The top board should be pulled down/together against the underlying one. Now I've discovered that it's quite difficult to pull the boards together. I've tried using regular decking screws like 4.5x50.

Any tips?

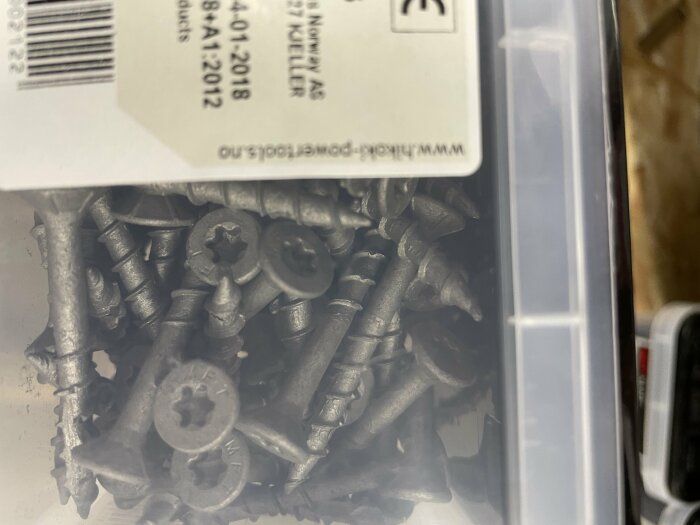

Use a screw that has 2 different thread pitches on the shank. This will give you good clamping force and pull the deck boards together. There are decking screws built this way. ESSVE, Gunnebo, Grabber, MFT, and others have this type of screw. If you're going to glue pressure-treated wood, as you have used on other occasions, PU glue is what you need.

https://www.bauhaus.se/trallskruv-essve-essdeck-max-c4-4-8x55mm-250st-fp

https://www.bauhaus.se/trallskruv-essve-essdeck-max-c4-4-8x55mm-250st-fp

The screws you are showing will be difficult to use because they rely on the different threads fitting exactly into both planks.

The principle must be that the head should pull the lower plank up into the upper one. For this to succeed, there should be maximum threading in the upper plank and the head should be large enough not to sink into the lower plank without pressing it against the upper plank.

The next screw to test if the purchased one doesn't work is.

Better if it were 55mm though.

The principle must be that the head should pull the lower plank up into the upper one. For this to succeed, there should be maximum threading in the upper plank and the head should be large enough not to sink into the lower plank without pressing it against the upper plank.

The next screw to test if the purchased one doesn't work is.

Better if it were 55mm though.

Too slow and becomes too complicatedLars Klein said:

You haven't considered using wooden dowels and polyurethane glue? Otherwise, drill a small hole in the rail and insert a shortened nail to mark where the dowel should be. Drill for the dowel in the rail and lower board and mount the dowel in the rail with glue. Let it dry. Glue the lower board and contact surface, mount with clamps, and wipe off excess glue with acetone. Guaranteed to hold, but of course difficult to disassemble!

Edit: and probably too difficult for me

It will work. They are designed to provide maximum clamping force between the joist and the decking board. The reason the threads are not directly under the head is to save your fingertips when screwing a lot 🙂

You're not in Sthlm? Because Nordbygg is currently taking place at the Stockholmsmässan, and there you can test both the screw I sent a link to and the WAF you sent a picture of.

You're not in Sthlm? Because Nordbygg is currently taking place at the Stockholmsmässan, and there you can test both the screw I sent a link to and the WAF you sent a picture of.

Gluing can be a solution that makes it possible to really screw "invisibly" from underneath. Unfortunately, I didn't think of that myself when I was working on a railing! I first tried with a horizontal board on a 45x45 beam, but it didn't hold because the board's 28 mm was not enough for the thread to manage to hold the board when it warped. My solution in the end was to screw from above and use both a horizontal and a vertical board underneath (both 28x120). The screws aren't very pretty to look at, but they hold firmly.

The screw should be able to hold it together even without glue or clamps, so you can do one section at a time and then move the clamps. I would rather borrow clamps or make a maximum of two sections per day so the glue joint has time to set, but it's doable. If you are not gluing, eat it as you do anyway, i.e., no difference.

Click here to reply

Similar threads

-

C4 corrseal for joining framework

Building Materials and Construction Technology -

Hur koppla ihop PEM 32mm Slang och utkastare / andra ändan PEM 32 Sland och Gardena Slang

Vatten & Avlopp -

Tja allihop ska dra kabel från ett vägguttag till en enpolig strömbrytare som ska tänd

El -

Dra ihop dag- och dränvatten

Vatten & Avlopp -

Koppla ihop bäck med dränering.

Trädgård allmänt