68,349 views ·

259 replies

68k views

259 replies

Newly laid floor flexes on 3 floors and in all rooms

If outdoor and indoor air have the same temperature, there is always an attempt to equalize. If the outdoor temperature is warmer than the indoor temperature with higher humidity, there will be a significant influx of moisture into all the wood, and naturally vice versa. If you are going to ventilate, it is advisable to do so when it is significantly cooler outside than inside with the same or lower relative humidity, as this dries out the indoor air. A dehumidifier is always recommended if there is high humidity indoors, over 70% relative is a measure I use when the dehumidifier runs in the basement in the summer when no heating is on in the house. A bonus is a cool and dry basement that doesn't have that "basement feeling" which easily occurs when the warm and humid outdoor air is cooled down and becomes even more humid, relatively speaking.

HiP Peter Petterson said:Hey hey!!!

Installed new flooring on 3 levels in the house.

The carpenters went down to the beam structure, mounted new joists on the old ones to level the floor.

Glued and screwed according to all the rules of the art.

Milled the floor chipboard, same thing there glued and screwed according to all the rules of the art.

Aluplates with the correct spacing in between mounted.

The floor, they say, was also laid with enough gap against walls, thresholds, etc.

Now to the problem: the floor seems to float on an air cushion almost everywhere. Both along the moldings and in the middle of the floor.

At portals where it is tightest, the floors creak and squeak as they have lifted significantly.

Short joints have started to have large gaps and are not tight in many places.

Big, big problems in other words.

Anyone have suggestions on what is wrong and solutions?

I suspect too little play along the walls and that the floor is under tension?

Perhaps I don't have a specific tip.. but just a little input as my floors and I have an odd relationship..

I hate bouncing floors, I don't mean the floor should be completely rigid (because that only happens if you have a concrete slab, with tiles on top), but "bouncy".. and "uneven".. and "raised".. and I've had them (have..) all.

Different houses, different problems..

Not all choices are right for all houses.. regardless of how correctly they're done. Old houses do not always function best according to "all modern rules of the art". They can react very differently to certain things..

I can say this.. we have redone the kitchen, bathroom, hall, and bedroom so far.. were supposed to do the living room this fall.. but contractors have a lot to do.

For us, it was about there being a bit too much distance between the floor beams. Tiles and some self-leveling compound in some places (including large furniture) have weighed everything down.. so for us, it was about putting supports in the basement (not furnished)... and getting everything to stop sinking.. and then aligning what's sunk.. (we attached new joists to the sides of the old ones).

I over-dimension everything.. so I asked them to put extra joists/cross beams too.. so I believe we now have cc30 in the kitchen..

But anyway, for us, it was posts/load-bearing walls required under the slab structure (it works to have larger dimensions on the floor joists.. if you can manage to fit them in.. and give them support from walls.. but just in our case, it was easier to put in some posts and steel beams)

No one seems to want to do our "passage room" (a lot of electricity, water, heating, and fiber running in the ceiling/floor below).. and the boiler in there must be able to be moved out.. so probably there will be a couple of movable props to press up the existing floor slab.. should the boiler need to be moved out. so it's possible!

Regarding the actual surface layer.. it is more mobile than you might think.. many old houses have a small molding outside the baseboard (I and official names.. hmm.. but could it be called a quarter round?).. to cover the wood's movement/gaps.. in certain periods of the year..

We have them.. where we don't have it.. we simply have gaps (a bit better where we actually redid the floors, but as I said.. old houses.. have quirks of their own.. and even if the floors are "flat", the walls aren't completely smooth (?)..

Both laminate and wood move.. and underfloor heating changes the environment too.. (especially if you turn it off, I guess / it's not on sometimes)..

We had problems with the short joints on a laminate floor in the previous house.. there was a "fault" with the floor I recall.. (all the short edges raised a fuss we used to say..). So THAT could be a "different problem".. (than gaps against the walls I mean).

If you have "bulges" on the floor, especially in the middle of the room.. I would assume something is under tension.. somewhere.. check behind all moldings.. if you "don't have a gap" somewhere.. (follow the floorboards from the bulge towards the wall...)

But you might also have bad luck.. we had a heating pipe under the floor chipboard that pushed up the floor.. :/

Not sure here, but isn't it Byggmax you should file a complaint with?P Peter Petterson said:

The phenomenon you're experiencing usually occurs when the parquet has a slightly higher moisture content on the top side compared to the underside. The top side becomes slightly longer and a small arch forms. The long sides’ click joints hold firm, so the floor only moves toward the walls under pressure and then forms the same arch again. However, the short joints can separate under pressure, especially when walking back and forth over the floor when an arch forms. They work out of position when they are angled against the arch.

So, since you've been so meticulous and ambitious, the floor may be fine when it assumes an even moisture level(?). The short joints then? They can be joined together with the help of two vacuum handles that are attached on either side of the joint. Press and use a rubber mallet. However, you must account for the fact that the strength of the short joints may have weakened, making them more likely to separate in the future.

Hope everything turns out well in the end!

So, since you've been so meticulous and ambitious, the floor may be fine when it assumes an even moisture level(?). The short joints then? They can be joined together with the help of two vacuum handles that are attached on either side of the joint. Press and use a rubber mallet. However, you must account for the fact that the strength of the short joints may have weakened, making them more likely to separate in the future.

Hope everything turns out well in the end!

Hello!S Spikrätaren said:The phenomenon you are experiencing usually occurs when the parquet has a slightly higher moisture content on the surface compared to the underside. The surface becomes slightly longer, forming a small arch. The long side click joints hold firm, so the floor only moves towards the walls under pressure and then forms the same arch again. However, the short joints might separate under pressure, especially when walking back and forth on the arched floor. They work themselves out of position when angled against the arch.

So, since you've been thorough and ambitious, perhaps the floor will be fine once it reaches an even moisture level(?). The short joints then? They can be pushed together using two vacuum handles placed on either side of the joint. Press and use a rubber mallet. However, keep in mind that the strength of the short joints might be weakened and could separate more easily in the future.

Hope everything turns out well in the end!

Thanks for what seems to be a really good answer. Is this something one can expect from the floor every time summer comes and there's high humidity?

Is there any way this is something I, as a customer, could claim a refund for, as the floor isn't meeting the expectations considering the work and money invested?

Newly laid floor with low RH then it switches to high RH over a long period, open windows and protective paper it's almost logical that such problems can occur. So during upcoming humid seasons when the house is occupied and materials in the floor and walls have assumed the same moisture content, the same high difference on the top/bottom side does not occur, but can then expand "evenly" out towards the walls. If there is a difference in different floors/quality and their movement, I know too little about. But the first step is, as you have thought; to get a documented analysis to start from. Because as it seems: You have done everything right and more, then the final result must be a flawless floor!

I think there may be factors here that have created a perfect mix to cause problems for you.P Peter Petterson said:

The three summers we've lived in our house, I've never experienced humidity levels as high as this summer. Especially last week, the trampoline effect I mentioned earlier in the hallway has been worse than ever. It took nothing more than the last 24 hours with lower temperature and lower humidity for everything to settle.

However, it's also possible that the floor has taken permanent damage and will be extra sensitive to increased humidity levels in the future.

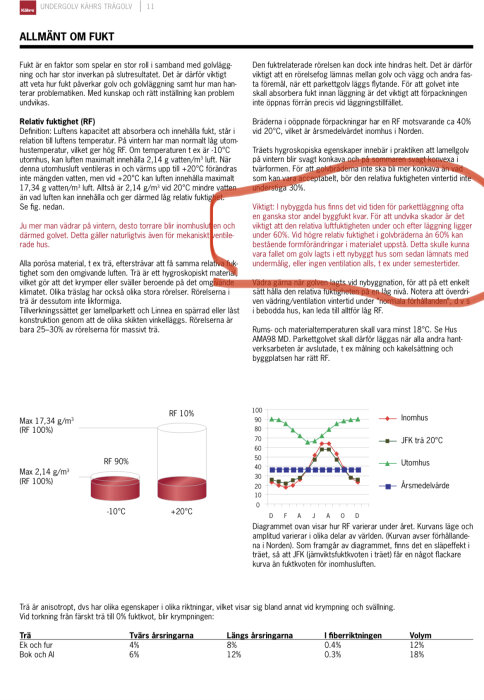

Attached is a page from Kährs' installation instructions. It seems like your construction during this humid time with paper and open windows may have caused the problems leading to a convex shape on the boards that might not revert.

Also note that it highlights that the floors should be installed last of all works. It's possible that Barlinek has the same stipulation in their instructions, and if so, it may be difficult to make claims against them.

Last edited:

But in what you attached, it actually says to ventilateX Jeppan said:I think there may be factors here that have created a perfect mix to cause problems for you.

In the three summers we've lived in our house, I've never experienced such high humidity as this summer. Especially in the past week, the trampoline effect in the hall I mentioned earlier has been worse than ever. And it didn't take more than the last day with lower temps and lower RH for everything to settle.

However, it's also possible that the floor has sustained permanent damage and will be extra sensitive with increased RH going forward.

Attached is a page from Kährs' installation instructions. It feels like your construction during this humid time with paper and open windows may have caused the issues that resulted in the convex shape of the boards which might not revert.

Note also that it highlights that the floors should be laid last of all works. It's possible that Barlinek has the same statement in the instructions and then it might be difficult to make claims against them.

The floors were laid under the right RH conditions, but after they were laid, no one ran around with an RH meter. The painter came back after the vacation and started hanging wallpaper and painting walls. The ceilings were already painted.

I don’t know what could have been done differently or if I, as the client, have any further responsibility in this matter? I have paid to have floors installed, subfloors replaced, the floor system adjusted, and new insulation injected.

By all accounts, you have laid the floor according to the rules of the art. I'm getting a bit tired of comments that when building something, the moon has to be in the seventh phase, there should be 3 dl of water poured on the fifth hour but not the sixth, and the beard should lie behind the thirteenth stone, otherwise, of course, nothing will work as intended.

Ps hope you can withstand these forces and get a floor that works as intended.

Ps hope you can withstand these forces and get a floor that works as intended.

No!S Stbk said:

CC 30 applies in bathrooms and there we have no problems. That renovation has probably been the smoothest of all spaces.

no it only applies in bathrooms with CC30.S Stbk said:

There we have used whole chipboards and electric underfloor heating to also have warm floors during the summer that dry up the floors effectively and CC30!

This sounds like the absolutely most sensible answer to your concerns.S Spikrätaren said:The phenomenon you're experiencing usually occurs when the parquet has a slightly higher moisture content on the top side compared to the underside. The length of the top side becomes a bit longer, forming a small arc. The long side click joints hold against it, so the floor only moves out towards the walls under load, only to form the same arc again. However, the short joints can separate under load, especially when walking back and forth over the floor during an arc formation. They work out of position when they lie at an angle to the arc.

So, since you've been so careful and ambitious, maybe the floor will be fine once it reaches an even moisture level (?). The short joints then? You can join them with the help of two vacuum handles that you attach to each side of the joint. Press and use a rubber mallet. However, you must account for the fact that the strength of the short joints may have weakened, making it easier for them to slide apart in the future.

Hope everything works out in the end!

The challenge is that it's only over time that you'll know it's solved, so to speak.

What it really says is that it's important the indoor humidity doesn't exceed 60%. If you've aired during this summer and moreover for long periods, you've definitely made the indoor climate well over 60% rh, which you've then trapped when the windows and doors were closed. Is it also an older house with natural ventilation? Then the indoor environment is likely to have been suboptimal for the floorboards for long periods; it's hard to ignore.P Peter Petterson said:But in what you attached, it actually says please ventilateThe floor was installed after all the wall plastering had already been done. The floor was laid in July right when the painter went on a 5-week vacation. Then it was covered and the carpenters continued with the installation of new interior doors, moldings, trim, new kitchen, new windows, etc., all while the floors were covered with milk paper.

The floors were laid under the right RH conditions, but after they were laid, no one checked with an RH meter. The painter returned after vacation and started hanging wallpaper and painting walls. The ceilings were already painted.

I don't know what could have been done differently or if, as the client, I have any further responsibility in this matter. I have paid to have floors installed, subfloors replaced, and the joists straightened with new insulation injected.

It explicitly states that all painting should be done before laying the floor.

It gets silly, as someone in a comment above pointed out, to criticize those who are trying to find explanations for why it turned out the way it did. Clearly, there's a possible explanation here. It shouldn't have to happen, maybe another floor would have held up. But now the situation has arisen, and the reasonable explanation seems to be long periods with too high humidity in the house. Who the responsibility falls on then? That's really something to ponder.

Hope it works out for you!

We had issues with flooring from Byggmax in the hallway and two rooms upstairs nearly 10 years ago. Very noticeable seams as if they had separated, and empty under the surface layer so it flexed down in one spot.

BM claimed it was due to dry air, even though we have a bathroom with a shower and bath adjacent to the hallway and an older Barlinek floor in our bedroom did not show the same problem.

BM claimed they were waiting for a response from the supplier and that it would probably be difficult, etc...

I stood my ground and asserted my rights, stating that I had purchased from BM and not from their supplier. I can't remember if ARN needed to be mentioned.

After some time, I got new flooring installed at their expense. The carpenter who removed and installed the new one found pieces where the short and long sides were not perpendicular, among other issues. No problems with the new floor.

We had issues with flooring from Byggmax in the hallway and two rooms upstairs nearly 10 years ago. Very noticeable seams as if they had separated, and empty under the surface layer so it flexed down in one spot.

BM claimed it was due to dry air, even though we have a bathroom with a shower and bath adjacent to the hallway and an older Barlinek floor in our bedroom did not show the same problem.

BM claimed they were waiting for a response from the supplier and that it would probably be difficult, etc...

I stood my ground and asserted my rights, stating that I had purchased from BM and not from their supplier. I can't remember if ARN needed to be mentioned.

After some time, I got new flooring installed at their expense. The carpenter who removed and installed the new one found pieces where the short and long sides were not perpendicular, among other issues. No problems with the new floor.