38,421 views ·

360 replies

38k views

360 replies

Load-bearing capacity of aluminum L-beam

If you have any form of open-cell insulation, you can expect the construction to weigh many times more after a few years. There's a thread somewhere where a spa cover was weighed after a few years and the weight had tripled, if I remember correctly.Huggedugge1 said:

Bernieberg said:

If you want to address the sagging in the middle, the beam running from long side to long side also needs to be stiffer.

Do you have any photos or sketches of what the entire joist construction looks like without the decking? The more info, the better the chance to come up with good and relevant suggestions.

Yes, I’m using 70 mm EPS/styrofoam that shouldn't absorb much liquid.D Derbyboy said:

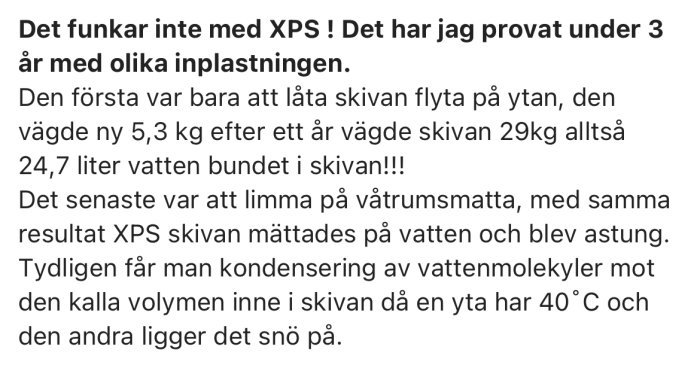

Unfortunately, it is specifically EPS that absorbs a lot of water. XPS and PIR absorb less water, though apparently quite a bit:

https://www.byggahus.se/forum/threads/bygga-lock-till-spabad.360624/page-2

Hopefully different with the pool, but I am doubtful.

https://www.byggahus.se/forum/threads/bygga-lock-till-spabad.360624/page-2

Hopefully different with the pool, but I am doubtful.

On the short side, which should have a span of just over four meters, you have placed a beam all the way and then reinforced it with two pieces. That doesn't help at all. The deflection is in the middle; I really don't understand what you were thinking with your construction.

If you had instead screwed in 2 pieces of 195 all the way, it would have been better, but even then, it wouldn't have been good.

If you had instead screwed in 2 pieces of 195 all the way, it would have been better, but even then, it wouldn't have been good.

Last edited:

XPS and EPS are not the same. But back to the main question. As I understand it, you think pipes are preferable. Where can one get help with bending?D Derbyboy said:

You're probably right. But... the solution?D Derbyboy said:On the short side that should have a span of just over four meters, you've placed a beam all the way and then reinforced it with two pieces. That doesn't help at all. The deflection is in the middle, I actually don't understand your thought process with your construction.

If you had instead screwed in 2 pieces of 195 all the way, that would have been better but even then it wouldn't have been good.

Right now, there are double 120*45 beams, one of which is tensioned to lift the open long side.Bernieberg said:

If you want to address the deflection in the middle, the beam running from long side to long side also needs to be stiffer.

Do you have any photos or sketches of how the entire frame construction looks without the decking? The more info, the better chance to come up with good and relevant suggestions.

I have no problem replacing the entire frame, but for it to work with a total weight of 1400 kg and not bend down, what dimensions and type of steel are needed?

But if you have used EPS, you will probably need to calculate a total weight around 5-6 tons at least (read the thread I linked to). Isn't it very foolish to have to make a third construction? You need to know the total load to choose the right pipe dimension. I don't know how you came up with 1400 kg, but have you accounted for the fact that soaking wet decking weighs much more than dry?

I still think the most reasonable solution is to lay out a ramp

I still think the most reasonable solution is to lay out a ramp

First of all, you need to know how much the structure actually weighs. The more exact the value, the easier it is to make the final construction.

Here, you need to know the weight of the material, how much extra weight it will pick up when it gets wet (both the decking and the insulation), as well as any potential snow load it might be subjected to.

Then you can calculate how much different pipes (I'm thinking VKR/KKR) of that length can handle holding up. Since you want the lightest construction possible, you also want to go down to the smallest possible dimension, and then make sure to pre-camber it as much as the deflection of the load on the structure is.

Here, it might also be worth considering the load cycles and the aging of the material (the steel) since such a large span and wind movements will cause some sway in the construction.

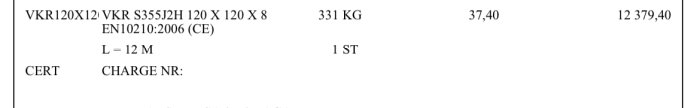

My professional experience tells me that if you use a couple of VKR pipes (at least one on the long side that hangs, but preferably one in the middle too) in the size 200x100x6.3, I would have curved them 5-8 mm in a smooth arc along the entire length.

Heavy? Yes, as hell, but unfortunately, that's "what’s required" for this type of span.

Edit: after seeing Derbyboy's post about a total weight of 5-6 tons (which I think sounds incredibly much), I would say that if you have that length freely supported as it is today and with weight close to that, you need to go even more in material dimension. 200x120x8 is probably the absolute minimum of what you need in that case. Guaranteed two pipes, and a pre-cambering of 12-15 mm.

Here, you need to know the weight of the material, how much extra weight it will pick up when it gets wet (both the decking and the insulation), as well as any potential snow load it might be subjected to.

Then you can calculate how much different pipes (I'm thinking VKR/KKR) of that length can handle holding up. Since you want the lightest construction possible, you also want to go down to the smallest possible dimension, and then make sure to pre-camber it as much as the deflection of the load on the structure is.

Here, it might also be worth considering the load cycles and the aging of the material (the steel) since such a large span and wind movements will cause some sway in the construction.

My professional experience tells me that if you use a couple of VKR pipes (at least one on the long side that hangs, but preferably one in the middle too) in the size 200x100x6.3, I would have curved them 5-8 mm in a smooth arc along the entire length.

Heavy? Yes, as hell, but unfortunately, that's "what’s required" for this type of span.

Edit: after seeing Derbyboy's post about a total weight of 5-6 tons (which I think sounds incredibly much), I would say that if you have that length freely supported as it is today and with weight close to that, you need to go even more in material dimension. 200x120x8 is probably the absolute minimum of what you need in that case. Guaranteed two pipes, and a pre-cambering of 12-15 mm.

No, forget the insulation. Maybe I mixed up the terms, but this insulation is used in floating docks.D Derbyboy said:But if you've used EPS, you probably need to calculate a total weight of at least 5-6 tons (read the thread I linked to). Isn't it very unwise to have to make a third construction? You need to know the total load to choose the right dimension for pipes. I don't know how you arrived at 1,400 kg, but did you account for the fact that soaking wet decking weighs much more than dry?

I still think the most reasonable is to lay out a ramp

Start from 1,450 kg in total weight.

A pre-bent pipe also gains a greater resistance to deflection than one that starts straight.. tricky as hellD Derbyboy said:

I can calculate it

And manufacture it

But most of the time, I go with my gut feeling when I pre-bend (and heat-straighten crooked) pipes.. Work experience, gut feeling, and material knowledge often surpass the most advanced calculations

Edit: Autocorrect is a bitch

Where does that total weight come from?Huggedugge1 said:

Does it include snow?

Dry decking?

Nails and screws?

Then you also have to account for the weight of the pipes...

Edit: Is the idea that you should be able to walk on the cover??