32,532 views ·

91 replies

33k views

91 replies

Elevator noise and other disturbances from the ceiling (live on the top floor)

Hello, it has been some time since I last wrote here. The construction workers have now done what sounds exactly like what you described with a new wall. An air gap of about 10 mm, maybe slightly less. Then a frame with mineral wool, two layers of plasterboard, and some form of plywood or something to stabilize the high wall as I understood it. This was on the recommendation of an acoustician. However, this has barely helped at all, maybe just a few decibels.N nomoD2 said:Hello,

Judging from what you write, I assume you live in a concrete building.

Vibrations are effectively transferred and unfortunately travel relatively far in buildings with concrete frames.

If you tap on the wall in your apartment closest to the elevator, you can easily determine if it is made of concrete or if the inner part of the wall is a lightweight wall consisting of plasterboards and steel studs. Elevator shafts are normally made of concrete. To reduce the risk of sound transmission through the elevator shaft wall, a standalone additional insulation of the elevator shaft wall is often specified during the design phase. Typically, this consists of 2x13 mm gypsum on a 45 mm steel stud and 45 mm mineral wool with about a 10-15 mm air gap between the steel stud and the concrete wall. If the wall against the elevator feels like concrete, this additional insulation is probably missing.

If the structural sound insulation of the elevator machine and guide rails is poorly executed, unfortunately, vibrations from the machine and guide rails will transfer to the concrete frame and then be emitted as structural noise in adjacent spaces. Sometimes, if the guide rails, the tracks along which the elevator operates, are not perfectly aligned, there is a risk that the elevator car will move sideways. This movement, in turn, causes scraping noises heard in adjacent spaces. By adjusting the alignment of the guide rails, this issue can be remedied.

You might consider contacting the board of the housing association where you live. The board can then contact the company that built the house and request measurement protocols from the control measurements usually done to obtain final certification for a new house. If you succeed in accessing this measurement protocol, check that the measurements actually include sound levels from the elevators. Usually, random checks are performed in a selection of apartments.

The minimum requirements according to the National Board of Housing, Building and Planning's building regulations (BBR, starting from BBR 20) are that the equivalent sound level (in areas for sleep, rest, and daily activities) must not exceed 25 dBA, and the maximum sound level must not exceed 35 dBA. These requirements apply around the clock. If the house is designed to meet, for example, sound class B, which has stricter requirements than BBR, the requirement for equivalent and maximum sound levels is tightened by 4 dB.

[link]

Hope you succeed in addressing the noise issues you describe.

Good luck!!

I have my doubts about how well the work has been performed. In the picture, you can see that the plasterboard does not reach all the way down to the concrete under the floor but stops at the same height as the wooden floor, is it supposed to be like that? Surely a properly executed job should give significantly better results?

They are not 100% done yet, but they say the remaining work will NOT improve the sound level.

It very much depends on what the problem was from the beginning. If it's the case that it's just the concrete wall that radiates sound and nothing else, then a free-standing wall like there will only help with sound over about 50-100 Hz. If the sound that is loud is low frequency, that solution can even worsen, then the wall should stand further out from the concrete wall.markaner said:

Hello, it has been quite a while since I last wrote here. The builders have now done exactly what you described with a new wall. An air gap of about 10 mm, perhaps a bit less. Then a frame with mineral wool and two layers of drywall, and some form of plywood or something to stabilize the high wall, as I understood it. This was on the recommendation of an acoustician. However, this has barely helped at all, maybe possibly a few decibels.

I have my doubts about how well the work was done. In the picture, you can see that the drywall does not reach all the way down to the concrete below the floor but ends at the same height as the wooden floor, is it supposed to be like that? Surely, properly executed work should yield significantly better results?

Now, although they are not 100% finished, they claim that the remaining work will NOT improve the sound level.

Do you know the thickness of the concrete wall towards the elevator shaft and if it is solid or a sandwich construction?

Okay! I think it's relatively high frequency anyway. Hard to say without experience though. The acoustician said it would help anyway. The wall against the elevator is 200mm solid concrete, I think.G gos84 said:It really depends on what the problem was originally. If it's just the concrete wall radiating the sound and nothing else, then a freestanding wall would only help with sound over about 50-100 Hz. If the sound that is loud is low frequency, that solution could even worsen it, then the wall should stand further out from the concrete wall.

Do you know the thickness of the concrete wall against the elevator shaft and if it is solid or a sandwich construction?

It's possible that the sound level now meets dBA, dBC, and max requirements but still sounds bad. If so, you should try to get them to report the sound levels in third-octave bands below 200Hz and compare them to the guidelines from the public health authority.markaner said:

https://www.folkhalsomyndigheten.se/publicerat-material/publikationsarkiv/f/fohmfs-201413/

If they are still above, it's something you can pursue further.

Otherwise, you might need to try changing the motor's vibration damping to something better, make the mounting of the frame the motor stands on and the frame itself stiffer/heavier or better anchored.

Moving the motor might be too expensive.

Have you been provided with any measurement reports?

Unfortunately, it might sound bad even if all the requirements are met, and then it stops there.

It may also be that the background level in the TS apartment is so low that the elevator noise, even if low in dB, can be disturbing even at approved noise levels. This is because the elevator noise is less masked by the background noise.G gos84 said:It may happen that the sound level meets dBA, dBC, and max requirements now but still sounds bad. If so, you should try to get them to present the sound levels in third-octave bands under 200Hz and compare them to the guidelines from the public health agency

[link]

If they are still above, it is something you can pursue further.

Otherwise, one might have to try changing the vibration damping on the motor to better, make the attachment of the stand the motor sits on and the stand itself stiffer/heavier or better anchored.

I think moving the motor is too expensive.

Have you not had access to any measurement report?

Unfortunately, it might sound bad even if all the requirements are met, and then it stops.

Last edited:

Now the acoustician was here again today and measured. The result showed 40 dB maximum. This is 8 dB higher than BEFORE the wall. But I think it sounds exactly the same, which makes me doubt that 32 dB was really accurate before. Now, however, the living room is emptied of some furniture and large parts are covered in plastic, so they said they would adjust for the new reverberation time, and then I assume the figure 40 decreases. I don’t know how much though. Previously, I received a report showing that the sound was approved. But since then, they have changed a few more things anyway, at least one of the actions had the opposite effect.G gos84 said:It might be that the noise level meets dBA, dBC, and max requirements now, yet still sounds bad. In that case, you should try to get them to report the noise levels in third-octave bands below 200Hz and compare them against the guidelines from the Public Health Agency

[link]

If they're still above, it's something you can pursue further. Otherwise, you might have to try replacing the motor's vibration damping with better ones, make the mounting of the frame the motor stands on and the frame itself stiffer/heavier, or better anchored.

Moving the motor, I think, would be too expensive.

Have you not received any measurement report?

Unfortunately, it might be that it sounds bad even if all the requirements are met and then it stops there.

This is definitely a contributing factor to why the sound is particularly disturbing in my opinion. But it has ranged from 32 to 42 while they have been trying various measures.N nomoD2 said:

I assume you measured the elevator noise when no construction activity was happening in your apartment. Otherwise, these values don't say much about the actual noise level from just the elevator.markaner said:

Elevator noise measurements require very low background levels otherwise, preferably significantly lower than the noise requirement that must be met with the elevator in normal operation.

If those who constructed the additional insulation skimped on the air gap when they attached the steel studs, there's a certain risk that the steel studs may have come into contact with the underlying concrete wall. If this happens, there's a risk that vibrations transmitted from the elevator motor's attachment to the concrete wall are passed on to the steel studs in the added insulating wall that has been built and then radiated as sound in your apartment. If this happens, the additional insulation can have a negative effect.markaner said:

The acoustician was here today again and measured. The result showed 40 dB maximum. This is 8 dB higher than BEFORE the wall. But I think it sounds exactly the same, which makes me doubt that 32 dB really was accurate earlier. Now, however, the living room is emptied of some furniture and large parts are wrapped in plastic, so they were going to adjust according to the new reverberation time said the acoustician, and then I assume the number 40 will decrease. I don't know how much though. Previously, I received a report showing that the sound was approved. But since then, they have changed some more things anyway, of which at least one of the actions had the opposite effect.

For the additional insulation to function as intended, it's necessary that the air gap between the concrete wall and the steel studs along the entire new wall is sufficient so that the new wall is truly standalone from the underlying concrete wall.

It's enough for a small section of a stud to be short-circuited by having contact with the concrete wall to cause a noticeable deterioration in the soundproofing enhancing properties of the additional insulation.

Of course, it also requires that the wall is sealed carefully with packing and soft sealant along all connections to adjacent partition constructions.

If you clearly hear sound from the floor and flanking walls, a standalone additional insulation will not solve the entire problem.

The most effective solution is always to address the source of the perceived noise disturbance, i.e., the elevator motor's vibration isolation and ensuring that the guide rails along which the elevator car's guide wheels run are perfectly aligned. Otherwise, there's a risk that the elevator car will sway sideways, which experience shows usually results in a scraping sound.

The air gap should be about 10mm, and I've asked several times if this is the case and always get the same answer. So, I have to assume that it is. I don't think they sealed with backing rod, just soft sealant for each layer.N nomoD2 said:If those who installed the additional insulation skimped on the air gap when mounting the steel studs, there is a risk that the steel studs may have come into contact with the underlying concrete wall. If this happens, there's a risk that vibrations transmitted from the lift motor's attachment to the concrete wall will transfer to the steel studs in the additional insulating wall that has been built, and then radiate as sound into your apartment. If this occurs, the additional insulation could have a negative effect.

For the additional insulation to work as intended, it is required that the air gap between the concrete wall and the steel studs is sufficient throughout the new wall to ensure that the new wall is indeed independent of the underlying concrete wall.

It only takes a small section of one stud being short-circuited through contact with the concrete wall to cause a noticeable degradation of the additional insulation's soundproofing-enhancing properties.

Naturally, it also requires that the wall is thoroughly sealed with backing rod and soft sealant along all connections to adjacent partition constructions.

If you clearly hear sound from the floor and adjacent walls, a freestanding additional insulation will not solve the entire problem.

The most effective solution is always to address the source of the perceived noise disturbance, i.e., the vibration isolation of the lift motor and ensuring that the guide rails along which the lift's guide wheels run are perfectly aligned. Otherwise, there is a risk that the lift car will start swaying sideways, which, based on experience, usually results in a scraping sound.

As you say, I suspect flanking transmission. But with that said, the wall that is now insulated is by far the worst, so it should have some effect.

I don't hear any scraping noise. But I hear a rumble as soon as the lift goes, which is probably the motor? The worst is, however, a banging noise that is relatively deep, which comes just when the lift stops. This noise comes from a box they refer to as frequency control. It was previously mounted on the rails but was then moved to be screwed directly onto my wall. This resulted in the sound becoming much louder, and thus it will also be moved back. However, this will not solve the problem, only make it a bit better.

Lived at the top of a stairwell with only two apartments on that floor. Our apartment had the stairs between the wall and the elevator while the neighbor lived wall-to-wall with the elevator. Our apartment was very well soundproofed, I think, but we still heard the elevator going up and down. The neighbor obviously heard much more.

If it can't be fixed, it will probably be a matter of moving because once you start being bothered by something that can't be fixed, it becomes an obsession.

If it can't be fixed, it will probably be a matter of moving because once you start being bothered by something that can't be fixed, it becomes an obsession.

Hard to say much without seeing some measurement data in tercio band.

But if I wildly guess:

The elevator motor causes structure-borne noise in the apartment-separating wall due to one or some of the reasons: wrong dampers/weak steel frame/too few inserts in the wall. The sound in the apartment is dominated by sound in the 63Hz tercio band, the new wall made the total construction worse (1–2dB) for sound insulation at just 63Hz (better for all higher frequencies) and the sound level in the apartment remains about the same.

Lekv,dBA meets the requirements, Lekv,dBC and LAFmax barely meet the requirements, but the public health agency's guidelines for low-frequency noise indoors are not met, but this is not reported as it is not required by BBR as long as Lekv,dBC is approved.

Of course, I could be completely wrong, I just wanted to guess a little

(Now I'm disregarding impact sound because they should be able to isolate that)

But if I wildly guess:

The elevator motor causes structure-borne noise in the apartment-separating wall due to one or some of the reasons: wrong dampers/weak steel frame/too few inserts in the wall. The sound in the apartment is dominated by sound in the 63Hz tercio band, the new wall made the total construction worse (1–2dB) for sound insulation at just 63Hz (better for all higher frequencies) and the sound level in the apartment remains about the same.

Lekv,dBA meets the requirements, Lekv,dBC and LAFmax barely meet the requirements, but the public health agency's guidelines for low-frequency noise indoors are not met, but this is not reported as it is not required by BBR as long as Lekv,dBC is approved.

Of course, I could be completely wrong, I just wanted to guess a little

(Now I'm disregarding impact sound because they should be able to isolate that)

You're not far off! The report showed that 80Hz was at 44 when the limit is 40 at one point, I know. But generally, the frequencies 63-100Hz seem to be the worst. But only 80Hz has been above the limit value.G gos84 said:Hard to say much more without seeing some measurement data in third-octave bands. But if I wildly guess: The elevator motor causes structure-borne noise in the party wall due to some reasons: incorrect dampers/weak steel frame/too few inserts in the wall. The sound in the apartment is dominated by sound in the third-octave band of 63Hz, the new wall made the total construction worse (1-2dB) for sound insulation specifically at 63Hz (better for all higher frequencies) and the sound level in the apartment remains about the same. Lekv,dBA meets the requirements, Lekv,dBC and LAFmax barely meet the requirements but the public health authority's guideline values for low-frequency noise indoors are not met but it is not reported because it is not required in the building code as long as Lekv,dBC is approved. I might be completely wrong, I just wanted to guess a bit(Now I am disregarding impact sound because they should be able to isolate that)

But how do you think the impact sound can be isolated? Apparently, there is something that turns on and off in the elevator attached to my wall and makes 40dB in my apartment. Have they messed up my additional wall or is it just a matter of trying to further dampen vibrations inside the elevator shaft? Thinking perhaps the 10mm air gap could be far too short for such low frequencies?

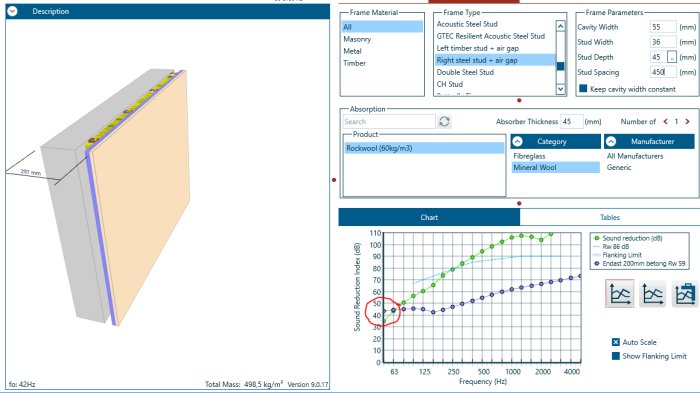

The wall is probably okay. I'm going to throw in a little image below to show what I mean might be a problem:markaner said:

You are not far off! The report showed that 80HZ was at 44 when the limit is 40 at one point, I know. But generally, frequencies 63-100Hz seem to be the worst. However, only 80hz has been above the limit.

But how can you isolate the impact noise, do you think? Apparently, there is some device that turns on and off in the elevator that is mounted on my wall and sounds 40dB in my apartment. Have they bungled my extra wall, or is it just about trying to further dampen vibrations inside the elevator shaft? I'm thinking maybe the 10mm air gap might be too short for such low frequencies?

To avoid degradation at low frequencies, you have to increase the extension quite a bit. But the problem is primarily that they need to isolate better what causes the sounds. That's unfortunately not in my area. However, the suppliers of the vibration isolators help calculate what needs to be done. It depends, as I understand it, on the weight of what's vibrating and the frequency that needs to be eliminated. It's the same principle for both the motor and for the thing that causes the impact noise.

Then another guess I have about elevators is that the cushion the motor is mounted on is sized for the elevator's maximum load, which never happens, and thus might be too hard.

Cool program I must say! Does this program also calculate structure-borne sound since I assume the effect of the wall differs depending on whether it's airborne or not? But as I understand it, the difference is very small for low frequencies? The impact noise is not the brake that previously sounded like a hammer at about 45 dB. Now it’s relatively dark, but doesn't feel like under 100Hz (hard to say without equipment and experience, of course). But if it’s around 200Hz, then a properly constructed wall should help, right?G gos84 said:The wall is probably okay. I'll throw in a small picture below that shows what I mean could become a problem:

[image]

In order not to get a deterioration in low frequency, you have to increase the extension by quite a bit. But the problem is probably mainly that they need to better isolate what causes the sounds. Unfortunately, it's not within my area. But those who deliver the vibration isolators help to calculate what needs to be done. It depends, as I understand, on the weight of what is vibrating and the frequency that needs to be eliminated. It's the same principle for both the engine and for the thing that causes the impact noise.

Another guess I have for elevators is that the cushion the motor stands on is dimensioned for the elevator's maximum load, which never happens, and it might be too hard.

However, I also think the key is vibration absorbers, as you say. On the thing that makes the impact noise, there are small, hard feet made of hard black plastic (like furniture feet). I would have thought you should use larger rubber pieces instead. Maybe one large rubber rectangle to distribute the vibrations?