155,661 views ·

317 replies

156k views

317 replies

Warning for Biltema's decking screw

One does not buy anything from Biltema that one does not expect to need replacing in the near future.

Hubcaps and such are perfectly fine there, but not building materials or electrical installation materials and the like.

Hubcaps and such are perfectly fine there, but not building materials or electrical installation materials and the like.

I've noticed the same thing with another wood screw that Biltema sells, article no. 87-0280 and other dimensions in that series, what crap.J Johan byggare said:I just want to share a warning about Biltema's decking screws, see pictures below. I laid 20sqm of decking in spring 2018, the first 15 with screws of an unknown brand and about 5sqm with Biltema screws. The unknown brand has no problem, but now I notice that about 90% of Biltema screws have simply broken. You couldn't find worse crap and I hope not many of you have bought and used the same junk!

[image] [image]

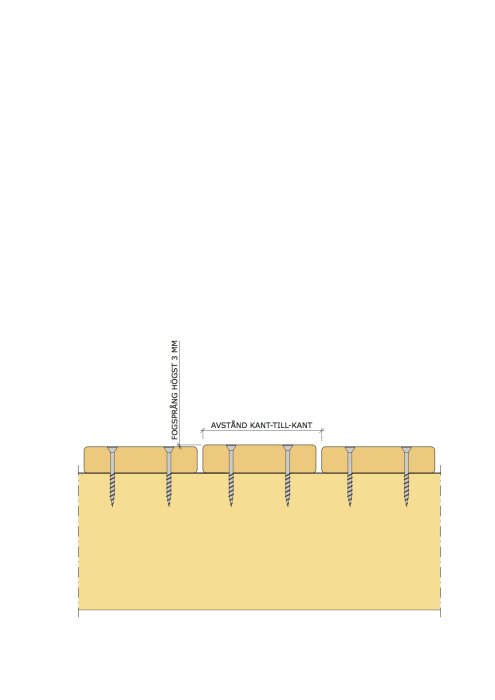

C4 is a corrosivity class, meaning the product is tested, approved, and intended for a specific outdoor climate from a corrosion perspective. C5 is intended for an aggressive environment. The breaking of screws is likely due to the steel's quality (strength) not withstanding the current stresses. When a wood construction is assembled, stresses always occur, which are to be absorbed by connectors. For decking laid in the spring/summer, it is normal for the decking to swell in the fall/winter due to increased relative humidity. If the decking is mounted directly against each other, there is an apparent risk of extra large stresses in the screws when the wood swells because some boards want to lift from the substrate. Such stresses are normally beyond the capacity of any screw – therefore, it is important to mount decking with a certain edge-to-edge distance according to the new recommendations from Svenskt Trä (see definition in the figure below). A deck of NTR/AB class impregnated pine with a dimension of 28x120 should be mounted with a 6 mm edge-to-edge distance. Feel free to consult Svenskt Trä’s recommendations: www.traguiden.se.Fario said:

I agree. Now I know that C4 is a worse choice, but when I bought at Byggmax:

“Hardened wood screw with countersunk head for use both indoors and outdoors. Surface treated with Protect 4 to withstand tough environments.”

I didn't think that several screws would break when I built a temporary structure with little load. I screwed planks directly against the beams, and when I dismantled, there were many screws that had broken, which wasn't noticeable when I screwed them in

Jonas Persson

Intresserad

· Stockholm

· 2 838 posts

Jonas Persson

Intresserad

- Stockholm

- 2,838 posts

That over 75% are breaking is extreme, there must be a common denominator increasing the risk of them breaking. I believe all mentioned brands have affected someone in the thread, so it's not brand-related, and no reseller wants to sell such crap. Two years ago, Byggmax had its own brand, blue boxes. Those screws were crooked in the box and disappeared from the range quite quickly.

I drove in 6-7000 deck screws from Grabber in the pool deck in 2017, and now after three years, everything is intact. Closest to the pool is stainless 2000 pcs and otherwise C4. However, Grabber's own screw head was crap.

But why are they breaking, a thought, how many of you have used a screwdriver with a hammer action and not a steady drive? The hammering imposes significantly greater stresses on the screw, which is weakened.

Furthermore, was it cold screws that were driven in or summer heat?

I drove in 6-7000 deck screws from Grabber in the pool deck in 2017, and now after three years, everything is intact. Closest to the pool is stainless 2000 pcs and otherwise C4. However, Grabber's own screw head was crap.

But why are they breaking, a thought, how many of you have used a screwdriver with a hammer action and not a steady drive? The hammering imposes significantly greater stresses on the screw, which is weakened.

Furthermore, was it cold screws that were driven in or summer heat?

There's probably not a big difference. I've snapped several stainless decking screws from Hornbach before I realized they are softer than regular decking screws, and you therefore have to watch out for knots when screwing. It's worked since then. But they could have been a little thicker.H Harald Blåtumme said:But do you think Biltema's stainless decking screw is worse than those from, for example, Byggmax or similar?

I don't think so. Sure, there's no problem snapping a decking screw in A2 stainless from Biltema, but I think the same applies to other stainless decking screws from other suppliers. Stainless screws that get stuck in a knot will inevitably snap in my limited experience; it's not "real steel" we're talking about at all.

A correction to my previous comments: The edge-to-edge distance for the current example should be 126 mm, not 6 mm as I stated. I apologize for the oversight.Holger Gross said:

C4 is a corrosivity class, meaning that the product is tested, approved, and intended for a certain outdoor climate from a corrosion standpoint. C5 is intended for an aggressive environment. The breaking of a screw is likely due to the steel's quality (strength) not being able to withstand the current stresses. When a wooden construction is assembled, stresses always arise that must be absorbed by the connectors. For decking laid in the spring/summer, it is normal for the decking to swell in the fall/winter due to increased relative humidity. If the decking is mounted flush against each other, there is an obvious risk of extra large stresses in the screws when the wood swells because some boards want to lift from the substrate. Such stresses are usually not withstood by any screw – therefore, it is important to install decking with a certain edge-to-edge distance according to the new recommendations from Svenskt Trä (see definition in the figure below). Decking made of pressure-treated pine class NTR/AB with dimensions 28x120 should be installed with a 6 mm edge-to-edge distance. Feel free to take part in Svenskt Trä's recommendations: www.traguiden.se.[image]

Same problem here with Biltemas.

We built two new decks in 2018 and extended one of them in spring 2019.

Deck 1 has most of the screws broken.

Deck 2, which was extended in spring 2019, already has several screws broken so that the boards

(28x145) have come loose.

Really trash.

“Oddly” enough, the part of deck 2 that was built in 2018 is holding up. I believe it was built with screws from byggmax actually.

Has anyone filed a complaint and got a response from Biltema regarding this?

We built two new decks in 2018 and extended one of them in spring 2019.

Deck 1 has most of the screws broken.

Deck 2, which was extended in spring 2019, already has several screws broken so that the boards

(28x145) have come loose.

Really trash.

“Oddly” enough, the part of deck 2 that was built in 2018 is holding up. I believe it was built with screws from byggmax actually.

Has anyone filed a complaint and got a response from Biltema regarding this?

I find it a bit surprising how many people have problems with decking and screws. I've built quite a few decks, stairs, gangways, hunting towers with pressure-treated wood and various types of decking screws, both stainless and coated, often from Biltema or Byggmax. Not on the west coast, but still, and the oldest deck has been there since the 90s. They are low-stress, very simple constructions made of very soft wood that practically lies there without screws. (Almost)

The idea that you would need to consider advanced metallurgy when installing a deck is unreasonable. I've never had any similar problems as mentioned in the thread, except for loosening a head against a knot or metal.

I never thought you could overthink decking screws.

Is there something else causing this? Hardwoods without pre-drilling? Wrong length? Or simply bad batches?

Because I know all the listed brands can and usually work perfectly fine.

The idea that you would need to consider advanced metallurgy when installing a deck is unreasonable. I've never had any similar problems as mentioned in the thread, except for loosening a head against a knot or metal.

I never thought you could overthink decking screws.

Is there something else causing this? Hardwoods without pre-drilling? Wrong length? Or simply bad batches?

Because I know all the listed brands can and usually work perfectly fine.

Hmm, the recommendation is to screw 30 mm from the edge, precisely to avoid too much force, I think. And is the plank thickness 22 or 28 mm? Not sure a different screw of the same size would hold in your case...H HenkB said:

https://www.svenskttra.se/nya-rekommendationer-for-laggning-av-trall/

L lars11 said:I find it a bit surprising how many have big problems with decking and screws. I've made quite a few decks, stairs, gangways, hunting towers with pressure-treated wood and various kinds of decking screws both stainless and coated, often from biltema or byggmax. Not on the west coast but still, and the oldest deck has been there since the '90s.

These are low-load, super simple structures made of very soft wood that almost stay in place without screws. (Almost)

To think you would need to consider qualified metallurgy when building a simple deck is unreasonable. I've never had similar problems as mentioned in the thread, except for occasionally hitting a knot or metal.

I never thought decking screws could be overthought.

Is there something else causing this? Hardwoods without pre-drilling? Wrong length? Or simply bad batches?

Because I know all mentioned brands can and usually do work perfectly well.

L lars11 said:I find it a bit surprising how many have big problems with decking and screws. I've made quite a few decks, stairs, gangways, hunting towers with pressure-treated wood and various kinds of decking screws both stainless and coated, often from biltema or byggmax. Not on the west coast but still, and the oldest deck has been there since the '90s.

These are low-load, super simple structures made of very soft wood that almost stay in place without screws. (Almost)

To think you would need to consider qualified metallurgy when building a simple deck is unreasonable. I've never had similar problems as mentioned in the thread, except for occasionally hitting a knot or metal.

I never thought decking screws could be overthought.

Is there something else causing this? Hardwoods without pre-drilling? Wrong length? Or simply bad batches?

Because I know all mentioned brands can and usually do work perfectly well.

I agree that all screws usually work. We (or mostly my husband) have built a lot. Owned several houses and never encountered this problem before. Only with the deck built in 2018 and ours in 2019 with the same type of screws from biltema. Otherwise, Biltema's stuff has always worked well.

I can't bother reading all the posts, but I can state that Biltema's screws really can be crap. I assembled a wooden deck many years ago with stainless screws from Biltema and they didn't break, but they did bend very easily, and with the current information, Biltema will henceforth be banned when it comes to more important screws. I guess that small screws for simpler use can still be used, and if they are cheaper than others, I'll make an exception for them. I'll take the opportunity to make a post on their FB page. Maybe it'll hit the nail...J Johan byggare said:I just want to share a warning about Biltema's decking screws, see the pictures below. I laid 20 sqm of decking in spring 2018, the first 15 with screws of an unknown brand and about 5 sqm with Biltema screws. There's no problem with the unknown brand, but now I notice that about 90% of Biltema's screws have simply broken. It's hard to find worse crap, and I hope not many of you have bought and used the same junk!

[image] [image]

The problem is not solely the quality of the screw but that fast-growing scrap wood of spruce that absorbs a lot of water and thus moves a lot is used, as well as poor installation. Use joists in the correct dimension and without knots against the floor. Buy slow-grown, preferably pine, and pre-drill with 2.5-3 mm, and lay with 5-6 mm edge measurement to get a fine floor without drying cracks and without broken or pulled screws. For this material, stainless or hardened screws can be used because the movement in the joists and floor becomes much less. Pre-drilling reduces the load on the screw and the tension in the wood around the attachment, allowing the wood to move slightly. Use quality screws in the correct length and a non-impact machine. Drive the screw head flush with the board using the machine, then tighten by hand with the machine an additional 1-1.5 mm, preventing excessive torque on the screw. Never use 22 mm wood, but at least 28 mm, which is normally of better quality. All of this costs 30-50% more but provides a worry-free deck floor. Before building, read up on wood quality and sorting. Have used screws of all brands without problems.

The extended part spring 2019 where we used Biltema screws and the screws have broken.

In some places, we had to screw in more screws = more ugly screw holes. What should we do? Replace all screws or insert new/extra ones at critical points?