38,369 views ·

360 replies

38k views

360 replies

Load-bearing capacity of aluminum L-beam

It may not be a solution to your current problem since you probably want to modify your existing solution and not start over, but I would likely base a roof on self-supporting sheets of the TP200 type (e.g., https://www.xn--pltgrossisten-qfb.se/takplat/tp200-sjalvbarande/#tab-id-2). They are available in variants that should handle your 8.4 m. Then you can cover the sheets with decking, but avoid direct contact between the treated wood and the sheet (place tar paper or similar in between).

HEA-beam becomes too heavy.

IPE- sways, we have noted. Bought 2 pieces of 10 cm and had to box them in with Corten steel and paint. Sways 3.5 cm...

Pipe is recommended by someone.

U-beam...

Profile pipe is what I am hoping for now.

Truss is what some others have suggested but...

Regardless of the solution, the maximum height is 23.5 cm so that I don't have to raise the "terrace" which just has 23.5 cm of free height.

IPE- sways, we have noted. Bought 2 pieces of 10 cm and had to box them in with Corten steel and paint. Sways 3.5 cm...

Pipe is recommended by someone.

U-beam...

Profile pipe is what I am hoping for now.

Truss is what some others have suggested but...

Regardless of the solution, the maximum height is 23.5 cm so that I don't have to raise the "terrace" which just has 23.5 cm of free height.

E Erik Lindroos said:It might not be a solution to your current problem since you likely want to modify your existing solution and not start over from scratch, but I would base a roof on self-supporting sheets of the TP200 type (e.g., [link]). They are available in variants that should handle your 8.4 m. Then you can cover the sheets with decking, but avoid direct contact between the impregnated material and the sheet (place tar paper or similar in between).

I would like to cover it with decking but am a bit concerned about the height. I must add 28mm in height for the decking and maybe 1 cm for the wheels.

A few questions:

1. Do you then screw the decking into the sheet with some suitable screw? (noted the comment about tar paper.)

2. One question is also about insulation... How do you get it there...

3. To reduce weight, can I then remove all the treated 120*45 if the sheet is self-supporting?

4. And what about the frame at 840 cm that goes over the pool which sags? It's likely to sag anyway?

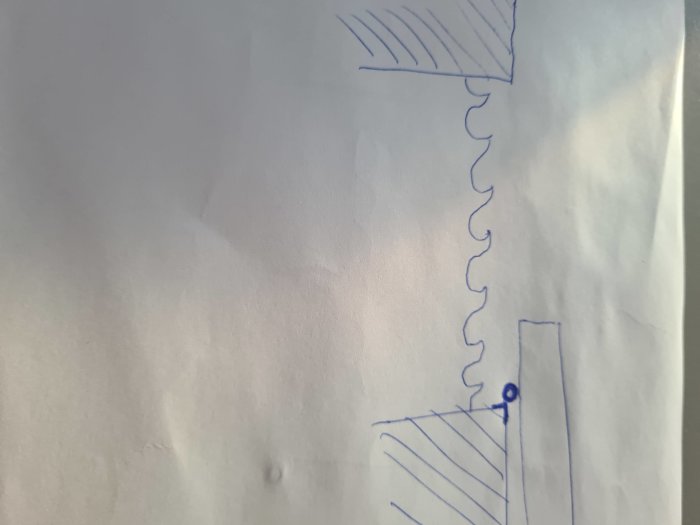

Am I thinking wrong, or even simpler, without compromising on visible design, would be to think the other way around and create a track under the pool cover in the middle. Perhaps install nogging between the compartments and a long flat bar so there are no gaps.

Then you add a sturdy hard roller (or steel roller) like the ones used to pull boats at the edge of the pool, maybe it needs to stick out depending on ground clearance, and let the pool cover roll on it. It doesn't need to be in contact all the time or handle super high loads, it's enough if the wheel lifts the cover the last bit.

An unscaled sketch here, not sure if the idea is clear...

Then you add a sturdy hard roller (or steel roller) like the ones used to pull boats at the edge of the pool, maybe it needs to stick out depending on ground clearance, and let the pool cover roll on it. It doesn't need to be in contact all the time or handle super high loads, it's enough if the wheel lifts the cover the last bit.

An unscaled sketch here, not sure if the idea is clear...

Something like that I had also considered, but it's a good idea to place most of the construction under the deck. Then it's "only" the support wheel that is visible.

Unfortunately, the dashed beams don't help much; I even think it gets worse as they add more weight without providing stiffness. The bearer does not become stiffer by this, and the ends of the dashed beams just follow along in the deflection without offering any significant resistance. I think you're considering them a bit like cantilevers, but they don't work like that if all beams are horizontal.Huggedugge1 said:

It's the bending stiffness of the bearer that you need to focus on.

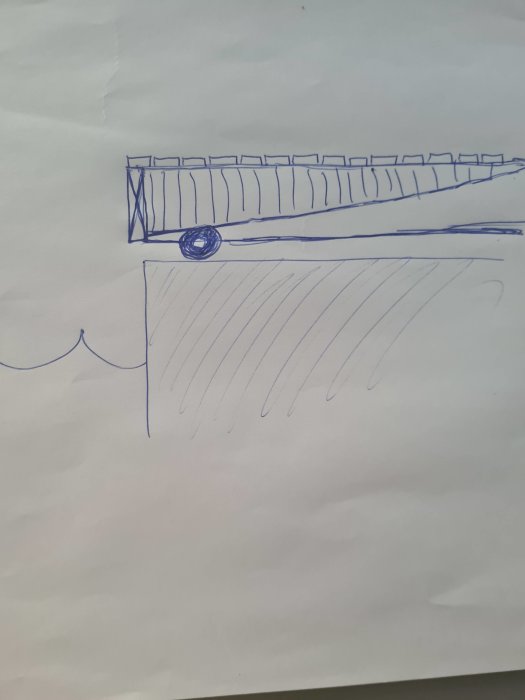

The wheel can also be hidden under the bridge when it is raised. If the edge of the bridge should not land too far in from the edge of the pool. Here is a schematic, like a cross-section. The dashed wedge is the track. The wheel catches the sloping track of the bridge and lifts it precisely over the edge. Nothing is visible from above. For the last part, they had 5 tracks distributing the weight, so the force against the wheel should be minimal...

The wheels are mounted inside the frame so they are hidden. However, they can only be concealed up to the axle where the attachment point is, which is 1.5cm free from the "floor."O o5kar said:The wheel can also be concealed under the bridge when it is lifted. If the edge of the bridge should not land too far in from the edge of the pool. Here is a conceptual sketch, of a kind of cross-section. The dashed wedge is the track. The wheel captures the incline of the bridge's track and lifts it just over the edge. Nothing is visible from above. Last time, TS had 5 tracks distributing the weight, so the force on the wheel should be minimal...

We've considered building up a "hill" on the rails to lift the cover just before it goes over the pool edge. However, it flexes quite a lot in the middle of the pool deck as you might have seen in the picture, so we need to find a way to create a stable frame. (Which is a challenge, as I understand…)

And this time, I want to make sure it is done right.

Yes, the height is borderline for it to work. At the same time, height is your best friend when it comes to counteracting deflection. A 153 mm total height sheet has roughly half the moment of inertia I, and gives double the deflection compared to the 203 mm high one I linked to. Maybe use 22 mm decking? It's a very short span between the metal sheet beams.Huggedugge1 said:

:smile: My current solution doesn't work and I'm looking for a solution. But a new solution that might work!

I'd really like to cover it with decking but I'm a bit concerned about the height. I have to add 28mm in height for the decking and maybe 1 cm for the wheels.

Some questions:

1. Do you then screw the decking into the metal sheet with some suitable screws? (noted the comment about tar paper.)

2. One question is also the insulation... How you get it in....

3. To reduce weight, can I then remove all the pressure-treated 120*45, if the metal sheet is self-bearing?

4. And what about the frame of 840 cm that goes over the pool that might sag? It will likely sag anyway?

I don't know exactly which screw is best, but the metal sheet companies should know. Then I'll modify this with just the tar paper. You might want to use something else depending on the metal sheet's rust protection. I've seen different statements now that I've googled, and it was unclear if it was for functional or aesthetic reasons that some advised against "bitumen products."

Insulation, missed that part... The metal sheet is probably not ideal from that perspective. Even if there were something that fits the profile, there are plenty of thermal bridges. It depends on how strict your requirements are.

With the right metal sheet, you should be able to remove the extra reinforcements, yes. The metal sheet should be self-bearing and according to tables, the 1 mm sheet thickness variant should withstand more than 100 kg/m^2.

The end of the long side also requires some thought as the metal sheet edge shouldn't flutter freely. I would ask a sheet metal worker to bend an L-profile of equivalent sheet metal quality that can be screwed/riveted into the profile sheet so it becomes a triangular longitudinal box for reinforcement. Then I would add a thinner wooden finish on the outside (for aesthetic reasons) and remove the heavy beam that's not needed.

What is the maximum deflection you can accept?

Interesting! The deflection can probably vary around 14 mm and upwards by raising the wheels. But the maximum height to get the tire under the “terrace” is 23.5 cm. Then it gets tricky…E Erik Lindroos said:Yes, the height is borderline doable. At the same time, the height is your best friend when it comes to countering deflection. A corresponding sheet with a total height of 153 mm has about half the moment of inertia I and gives twice the deflection compared to the 203 mm high one I linked to. Maybe use 22 mm decking? It's a very short span between the sheet-purlins.

I'm not exactly sure which screw would be best, but sheet metal companies should know. Then I should modify this with tar paper. It might be necessary to use something else depending on the sheet's rust protection. I've seen different information now when I've googled, and it was unclear whether it was for functional or aesthetic reasons that some advised against "bitumen products."

Insulation, I missed that part... The sheet may not be ideal from that perspective. Even if there is something that fits the profile, there are plenty of thermal bridges. It probably depends on how strict the requirements are.

With the right sheet, you should be able to remove the additional reinforcements, yes. The sheet should be self-supporting, and according to the tables, the variant with 1 mm sheet thickness should withstand more than 100 kg/m^2.

The end of the long side also requires some consideration as the sheet edge should not flutter freely. I would ask a sheet metal worker to bend an L-profile of the equivalent sheet quality that can be screwed/riveted to the profile sheet, creating a triangular longitudinal box as reinforcement. Then I would put a thinner wood cladding on the outside (for aesthetic reasons) and remove the heavy beam that is not needed.

What is the maximum deflection you can accept?

If I calculate correctly, the deflection due to the sheet's own weight is about 5 mm over an 8.4 m span (TP200). Quite independent of sheet thickness. Then you have to add decking, insulation, and snow, and then thicker sheet is better.Huggedugge1 said:

As a comparison to the figures previously given for the stainless-steel square "tube" with 6700000 mm^4 moment of inertia:

A sheet, 1 mm thickness, 854 mm width: moment of inertia 8100000 mm^4

Sheet thickness 1.5 mm: 12000000 mm^4.

So, a sheet is stiffer than the tube, and you will distribute the load (whatever it ends up being in total) over five sheets.

Absolutely wonderful to get this help!!! Super thanks!!!E Erik Lindroos said:If I calculate correctly, the deflection due to the plate's own weight is approximately 5 mm over an 8.4 m span (TP200). Quite independent of plate thickness. Then you have to add decking, insulation, and snow, and thicker plate is better.

As a comparison to the figures previously given for the stainless steel square "pipe" with 6700000 mm^4 moment of inertia:

A plate, 1 mm thickness, 854 mm width: moment of inertia 8100000 mm^4

Plate thickness 1.5 mm: 12000000 mm^4.

A plate is therefore stiffer than the pipe, and you will distribute the load (whatever it becomes in total) over five plates.

But… what should I use as a frame that doesn't flex? Steel? Corten? Dimension?

Huggedugge1 said:

The wheels are on the inside of the frame, so they are hidden. However, they can only be hidden up to the axle where the attachment point is, which is 1.5cm free from the "floor."

We have considered building a "hill" on the rail that lifts the lid just before it goes over the pool edge. However, it flexes quite a bit in the middle of the pool deck as you might have seen in the picture, so we must find a way to get a stable frame. (Which is a challenge, as I understand…)

And this time I want to know that it will be right.

I won't nag anymore, but your current wheels are in the bridge itself that moves, right?

My proposed wheel would be fixed in the ground.

My slanted rail gives the same effect as your intended hump on the ground rail but does not interfere with the rest of the function.

-but I might have misunderstood the problem...