7,457 views ·

22 replies

7k views

22 replies

How to deal with these roof trusses

Member

· Västra Götaland

· 1 849 posts

I say why truss when beam is simpleR Relaxia said:Story of my life

But why does it have to be so complicated then?

I say - does it matter?

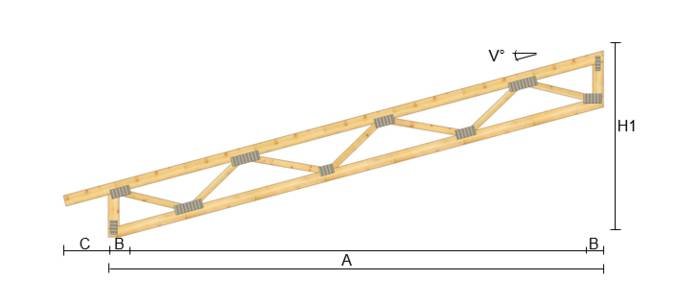

- I want a bunch of trusses c-c 1200.

- There are truss manufacturers who both calculate and manufacture.

- The manufacturer nearby has timber for trusses c-c 600. He suggests setting them in pairs to achieve c-c 1200 where I want, but doesn't know the distance at which they should be nailed together...

You say - don't make it complicated!

But you can also use double trusses, I would get a price for both and choose accordingly.

Good luck! No problems

Since I haven't seen any drawings, it's difficult to give specific comments, but there are some general aspects that might interest more than just TS. If a consultant, such as a structural engineer, has been hired to provide technical documentation for a building, it is very common in professional contexts for the specified component to be replaced with another considered equivalent or better. Such assessments should be handled by a KA. The point is that there is a design calculation in place that is tailored to the local conditions. If a supplier is to be used for calculations as well, there must be an agreement with the supplier that obliges them to take responsibility for their calculations.

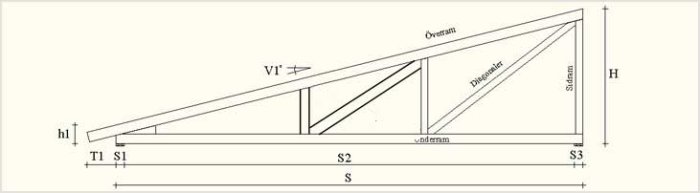

Looking at the span, a shed roof truss with common construction wood is fully possible. What complicates it a bit is that it should cantilever 80 cm beyond the outer support, thereby incurring a small torsional moment that requires a certain beam height over the support. This consideration plus the desire for a 7-degree roof pitch results in a relatively high height at the innermost point. An alternative to a truss is a shed-shaped glulam beam. I don't know which will be the cheapest in the end. Glulam tends to be about three times as expensive as regular wood in terms of volume, but here there's quite a bit of labor involved. Then there are some other aspects that could also influence the choice.

Exactly sofahlis said:

Now I've got an answer on how they should be nailed together. Upper and lower frame two nails c-c 200, diagonals c-c 300.

But does it have to be nails? And due to nail plates they won't be flush.

Say you happen to place a sheet of suitable material (plywood?) between the beams before screwing them together. Would that be negative in any way?

Click here to reply