68,456 views ·

47 replies

68k views

47 replies

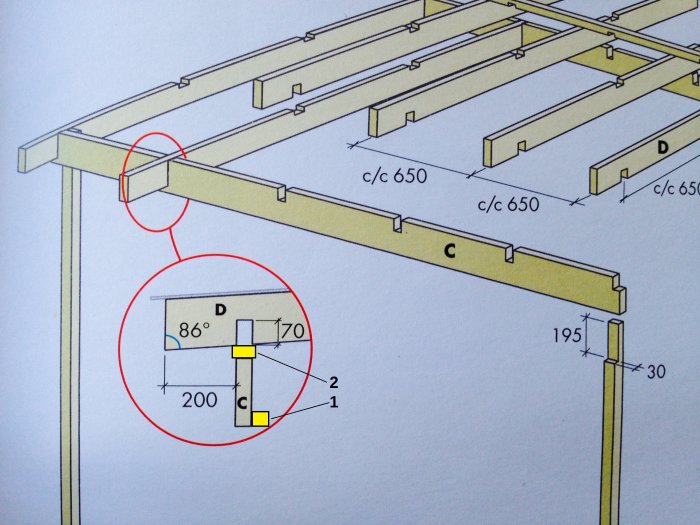

How much are top plate and truss strength affected by notches according to the picture?

You can certainly succeed with your construction, and being really meticulous with the cutouts contributes as well. However, I would take two other measures that wouldn't significantly affect the appearance but would add quite a bit in other respects.

1. To counteract the splitting mentioned by KOW and at the same time increase the strength of the carrying beams, screw a 50x50 on the inside and underside of the beams for the rafters to rest on, while also stiffening the beam at the appropriate place away from the neutral axis.

2. Instead of recessing the crossbars that the roof attaches to, fasten the outermost ones over the topside of the beams to close that side in terms of force, bevel the top edge of the beams so that everything fits snug there. With reasonably slender dimensions of the crossbars, they don't interfere much even if they are on top.

1. To counteract the splitting mentioned by KOW and at the same time increase the strength of the carrying beams, screw a 50x50 on the inside and underside of the beams for the rafters to rest on, while also stiffening the beam at the appropriate place away from the neutral axis.

2. Instead of recessing the crossbars that the roof attaches to, fasten the outermost ones over the topside of the beams to close that side in terms of force, bevel the top edge of the beams so that everything fits snug there. With reasonably slender dimensions of the crossbars, they don't interfere much even if they are on top.

Quoting the tool guru from another thread.

"Speaking of joist hangers and skewed screwing.

I never use joist hangers or angles in visible mounts, looks awful. Instead, screw-glue a 45x45 on the support beam and place the trusses on this. One screw from above and one from below, and it's set.

See the picture to understand what I mean."

http://mobil.byggahus.se/forum/attachment.php?attachmentid=106348&d=1393368788

And I agree, this is how it should look!

"Speaking of joist hangers and skewed screwing.

I never use joist hangers or angles in visible mounts, looks awful. Instead, screw-glue a 45x45 on the support beam and place the trusses on this. One screw from above and one from below, and it's set.

See the picture to understand what I mean."

http://mobil.byggahus.se/forum/attachment.php?attachmentid=106348&d=1393368788

And I agree, this is how it should look!

if you want rafters and support beam at the same level, galvanized steel joist hangers are the only option. Notching weakens the support beam terribly (not the top plate, that's something completely different).

If you want to double, you can use the neighboring beam as 120x45, and then it determines the load capacity, i.e. it's not enough.

If you're after the appearance, I recommend forged iron shoes, which can be made from angle iron.

If you want to double, you can use the neighboring beam as 120x45, and then it determines the load capacity, i.e. it's not enough.

If you're after the appearance, I recommend forged iron shoes, which can be made from angle iron.

Member

· Stockholms Län

· 702 posts

So the entire eave should hang in joist hangers? I'm not sure how far I'm planning, but maybe 30-50cm. Doesn't feel like you'd want to be out on that roof. Do you think it will be sturdy?Mattiaz said:

There is a big difference in durability if you take extraction at the end (as in the picture from Peter2400) or in the middle.

What I tried to describe in #16 is similar to the image in #18 except the principle is used at both beams and with notches also for overhangs. If done this way, and possibly also point 2, there are no issues with strength or stability, and it is also sleek and tidy.

Member

· Stockholms Län

· 702 posts

Do you mean a 45x45 on each side of the outer support beam?GK100 said:

And a notch in the top of the support beam and the bottom of the rafter? Or just notch the rafter/ridge?

Basically just these two parts and of course with the cutouts you mentioned from the beginning. C can be slightly beveled at the top so that 2 follows the slope of D when it is in place. And the tip of D that rests against 1 can also be adjusted so they fit there. And the same but reversed at the other beam, you place joists like 2 across as many as needed for the rest of the roof.

Build a regular wall. Place the load-bearing beam on the inside of the wall and on the outside of the studs, not recessed as is done when reinforcing a wall. The trusses will now rest on the load-bearing beam, which you should fasten with heavy screws.

Yes, what you want to achieve is probably quite difficult. I know the correct solution, will get to that at the end of the post.

But one solution could be to simply hang the rafters on the inside of the load-bearing beams as described in post #19, but you can make it a bit nicer as described in posts #16 and #18.

Then the question is how to achieve an overhanging eave, if desired, which I assumed you wanted.

It might be possible to screw in short beams diagonally and then reinforce them with flat iron on top, screwed into both the rafter and the eave beam pbs on the load-bearing beam.

I'm really not sure if this will work, it feels like there's a risk the eave will start to sag a bit after a year or so, but I can't come up with a better idea.

But, well, I know the right solution , such a construction should of course be welded together from steel beams (/square tubes).

, such a construction should of course be welded together from steel beams (/square tubes).

But one solution could be to simply hang the rafters on the inside of the load-bearing beams as described in post #19, but you can make it a bit nicer as described in posts #16 and #18.

Then the question is how to achieve an overhanging eave, if desired, which I assumed you wanted.

It might be possible to screw in short beams diagonally and then reinforce them with flat iron on top, screwed into both the rafter and the eave beam pbs on the load-bearing beam.

I'm really not sure if this will work, it feels like there's a risk the eave will start to sag a bit after a year or so, but I can't come up with a better idea.

But, well, I know the right solution

Member

· Stockholms Län

· 702 posts

It would have been slim and nice! But if I have trouble dimensioning wood where there's plenty of free calculation help, a welded steel construction might be a notch worse. Maybe put up a Haki with channel plastic on  .

.

Joking aside, I'm leaning towards skipping the roof overhang and moving the outer load-bearing beam out instead. Then you can probably attach the gutter directly to the beam as well.

Joking aside, I'm leaning towards skipping the roof overhang and moving the outer load-bearing beam out instead. Then you can probably attach the gutter directly to the beam as well.

There is another thread with a similar theme. There, the use of a joist hanger was also discussed as a less appealing method. A better suggestion was to attach a 45x45 rule to the beam edge, flush with the underside, so that you get a shelf to place the roof truss beam on. There you can easily remove 45 mm without reducing strength.