4,730 views ·

27 replies

5k views

27 replies

Floor joist dimension - 5.6 meters

Hi, I have some questions regarding how I shouldJ justusandersson said:

Hello again.J justusandersson said:

I have a few more questions:

How should I think about anchoring the posts in the ground? Buy ready-made footings or cast my own? Do I need ground insulation to avoid frost damage? Ready-made or own concrete slabs on a bed of gravel/sand?

If it helps, the priority is:

1. That it holds.

2. Cost.

3. How easy it is to do yourself.

4. How it looks in the basement.

The ground is hard clay with lots of stones in all possible sizes which makes hand digging very difficult.

What is the load that the post shoe needs to withstand? Should I have adjustable ones?

The calculation process is 1 Calculate the column loads, 2 Check the allowable ground pressure (till 200 kPa, firm clay 100 kPa), 3 Calculate the necessary pad dimension (cross-sectional area) with regard to 1 and 2. 100 kPa (kilopascals) is 100,000 N/sqm. If the pad's bottom area is 25x25 cm, it can only support about 6 kN at max 100 kPa ground pressure, which may be insufficient in your case. You can combine a purchased pad with casting a larger footing to place the pad on. If the column loads are very large, you will probably need to cast the entire foundation on site.

It's not a difficult job. Renting an electric jackhammer will make digging easier. It's advantageous that the ground is hard. Let the post anchor only hold the column in place laterally. You should not use adjustable post anchors here.

Make a simple sketch of how you envision the whole thing right now so that you can get help calculating the column loads.

It's not a difficult job. Renting an electric jackhammer will make digging easier. It's advantageous that the ground is hard. Let the post anchor only hold the column in place laterally. You should not use adjustable post anchors here.

Make a simple sketch of how you envision the whole thing right now so that you can get help calculating the column loads.

Do I need to hire someone to assess the ground/calculate allowable ground pressure, or can I base it on 100 kPa according to my own assessment of firm clay?J justusandersson said:The calculation procedure is 1 Calculate the column loads, 2 Check the allowable ground pressure (moraine 200 kPa, firm clay 100 kPa), 3 Calculate the necessary footing dimension (cross-sectional area) with regard to 1 and 2. 100 kPa (kilopascals) is 100,000 N/sqm. If the base of the footing is 25x25 cm, it can only bear about 6 kN at a maximum of 100 kPa ground pressure, which is probably too little in your case. You can combine a purchased footing with casting a larger foundation base to place the footing on. If the column loads are very large, you'll likely need to cast the entire foundation on-site.

It's not a hard job. Rent an electric breaker to make digging easier. It's an advantage if the ground is hard. Let the post shoe only keep the column in place sideways. You shouldn't use adjustable post shoes here.

Make a simple sketch of how you currently envision the whole thing, and you can get help calculating column loads.

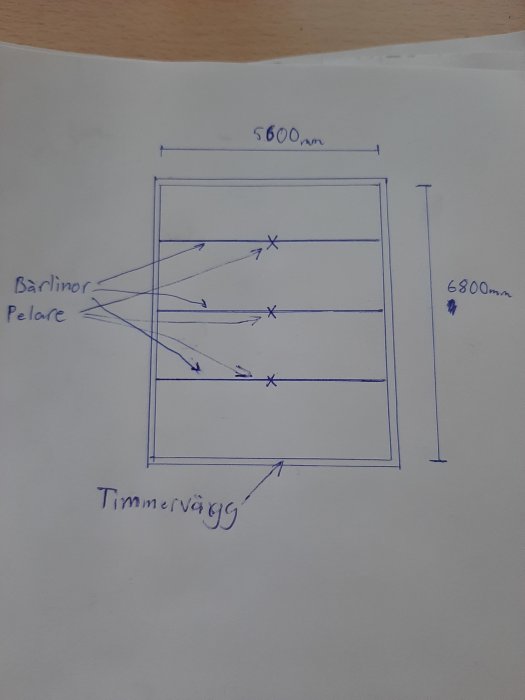

The floor's construction is the same as you suggested with three transverse beams (5.6m long 90x225 laminated beams with a center spacing of ~1700mm) with a post (also laminated wood, 90x90) in the middle of each beam. Floor joists made of construction timber above them, then solid wood flooring. I believe your example was calculated on 3 kN/m2 useful load.

There will of course also be a beam of construction timber along each short side, but since it can be attached directly to the log wall, it is not relevant for this and therefore not shown.

There is really nothing preventing me from having two (or more) posts per beam. More footings and laminated columns, and perhaps a bit more work, but if it would be a better solution, I have no objection to it.

What is meant by "Let the post shoe only keep the column in place sideways"? That the actual post shoe should not be load-bearing?

Do you have any opinion on ground insulation? How deep should I dig?

Thanks for the tip about the breaker, it will probably make the digging much less frustrating!

Then you end up with a pillar load of just under 20 kN per pillar.

I find it hard to imagine that you would need ground insulation, it is under a roof. There's no risk of frost heave, is there? If there's water, I suggest drainage. I think the ground sounds more like moraine with many stones of different sizes. In the past, they always placed barns on land that couldn't be cultivated.

One of my first summer jobs was digging a lot of holes in the ground on an industrial site, so a bit of technique probably remains.

Yes.B Barriospurer58 said:

I find it hard to imagine that you would need ground insulation, it is under a roof. There's no risk of frost heave, is there? If there's water, I suggest drainage. I think the ground sounds more like moraine with many stones of different sizes. In the past, they always placed barns on land that couldn't be cultivated.

One of my first summer jobs was digging a lot of holes in the ground on an industrial site, so a bit of technique probably remains.

Okay, yes, it is under a roof, but I think it still gets about as cold as it does outside under there? The barn is built on a slope, so the "basement" is more like the lower floor of a split-level house. The dry-stone foundation walls form the basement walls, one is covered with soil, two partially covered with soil, and the last one has the stone foundation completely exposed. There is also a door opening to the basement on that wall. But frost may not be a major problem since it is covered, because radiant heat is trapped inside?J justusandersson said:That puts you at a column load of just under 20 kN per column.

Yes.

I find it hard to imagine you would need frost protection, it is under a roof. There's no risk of frost heave, right? If there's water, I suggest drainage. The ground sounds more like moraine with many stones of different sizes. People used to always place barns on land that couldn't be farmed.

One of my first summer jobs was digging a lot of holes in the ground at an industrial site, so I remember some of the techniques.

It might very well be counted as moraine. It's hardly usable, it was a real pain to dig a hole to plant a small currant bush. The old plot designation was "Stenbacken 1", and I can only confirm that is accurate.

It doesn't seem to be particularly wet anyway.

The cold itself is probably not an issue, but it is in combination with moisture that it can become a problem.

I'm thinking spontaneously that I'm unsure about the ground, and therefore assume clay. Based on that, I conclude that 50x50cm suffices for a load of 25kN.J justusandersson said:

My plan right now:

Excavate (how much? Half a meter? More?), a dm of gravel at the bottom, cast a 0.25m² slab about 10cm thick, cast a pre-made footing into it, fill around the footing and compact well.

Does that sound reasonable? Do I need a geotextile under the gravel?

Hello again.J justusandersson said:

I have a question about the floor. It seems I've waited too long to order flooring, and now I'm having trouble finding 30mm thick pine floors as intended. I'm considering laying chipboard flooring to walk around inside until the flooring arrives, and ordering a floor that will be delivered in the fall (seems to be 6+ weeks delivery time on most floors I've found).

How thick of a solid wood floor in combination with 22mm glued and screwed chipboard should I then have? 22mm chipboard + 14mm wood floor doesn't make a 36mm composite floor since the floor is only screwed, right?

It's a matter of taste. 14 mm probably works well, but thicker wooden floors provide a more solid feel. At the same time, it increases the height. If you're going to install it floating, maybe 14 mm is preferable. There are certainly others who are better at assessing this particular aspect.

I wasn't planning to install it floating as I have heard that floating floors can be problematic with heavy "furniture" (woodworking machines). The plan was to screw the floor either into the chipboard or through the chipboard down into the floor joists. Not sure which is better.J justusandersson said:It is a matter of taste. 14 mm will probably work fine, but thicker wooden floors provide a sturdier floor. At the same time, you are increasing the height. If you are going to install it floating, maybe 14 mm is preferable. There are certainly others who are better at assessing this particular aspect.

Increasing the height is not a problem, there is room for that.

I was mostly wondering how to compare, for example, a 30mm solid wood floor with a screwed and glued 22mm chipboard floor and a thinner solid wood floor on top, in terms of durability. I don't mind increasing the thickness of the floor if needed for a stable floor, but it's probably expensive, so I prefer not to buy unnecessarily thick for that reason.

Maybe I'll start my own thread for this question, but I thought I could ask here first.

Why not order a rough (2") solid wooden floor locally from a sawmill? That way, you'll have flooring for your, your children's, and grandchildren's needs.

If you choose dry spruce, you should get an inexpensive floor that should be suitable for the woodworking shop.

If you choose dry spruce, you should get an inexpensive floor that should be suitable for the woodworking shop.

I apologize for my recent response, I didn't remember all the previous conditions in the thread. Consider the particleboard as a temporary solution and screw-glue it for better integration with the joists, but then lay a solid wood floor about 30 mm thick. Or do as @fribygg suggests, order a 2-inch tongue-and-groove spruce floor and scrap the particleboard. It will definitely be cheaper. An alternative is to invest in plywood instead. For example, 24 mm birch plywood with a simple veneer. I believe such a board has at least 15 layers. It becomes incredibly sturdy, can't be compared to particleboard.

Thank you for the answers, I will check the delivery times for a two-inch floor.

Click here to reply

Similar threads

-

Om äldre PEM dimensioner och PRK-kopplingar

Vatten & Avlopp -

Installera ny radiator - hjälp med dimensioner på rör och anslutning

Värme allmänt -

FTX - Dimension, aggregat, isolering m.m.

Ventilation -

Tryckt virke golvbjälklag - vad göra?

Fritidshus -

Extension - Beam/Floor Joists - Sizing

Building Materials and Construction Technology