376,597 views ·

138 replies

377k views

138 replies

Casting a concrete countertop - pictures, questions..

there are also clips on youtube.

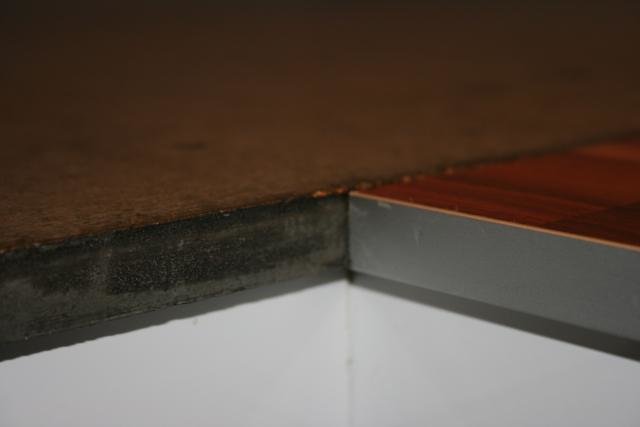

I have read this thread with great interest. I have previously cast countertops for kitchens. The countertops have been 16 mm thick to align in height with the sink.

I have experimented a lot with different concrete qualities to achieve the right surface. I have not wanted to grind because I do not want to see the ballast material.

The best result I have gotten is with expansion concrete with 0-1 mm ballast. No pores at all and the surface becomes completely smooth without polishing.

The only difficulty is that the countertops tend to warp somewhat after a few weeks. I know that there are other qualities with high flowability that do not have the expanding properties, but I have not managed to obtain this. I have reinforced them with a thin rod network.

Then the countertops are treated with concrete oil which gives water-repellent properties. I have also tried water glass and it has worked okay.

Regards

I have experimented a lot with different concrete qualities to achieve the right surface. I have not wanted to grind because I do not want to see the ballast material.

The best result I have gotten is with expansion concrete with 0-1 mm ballast. No pores at all and the surface becomes completely smooth without polishing.

The only difficulty is that the countertops tend to warp somewhat after a few weeks. I know that there are other qualities with high flowability that do not have the expanding properties, but I have not managed to obtain this. I have reinforced them with a thin rod network.

Then the countertops are treated with concrete oil which gives water-repellent properties. I have also tried water glass and it has worked okay.

Regards

Expansion concrete? Googled it and didn't get much wiser.

I have cast a concrete countertop for an outdoor kitchen that is otherwise built in lightweight concrete blocks. I will gladly share my experiences later. But I am a bit uncertain about how to finish the surface. When I asked at the paint store today, they didn’t have a suitable oil, and they didn't think wax would hold up outdoors. I prioritize protection against freeze-thaw damage and of course, I don't want it to become gross with food scraps seeping into the surface. I prefer a "wet look," but that's not as important. Any ideas on the type of product? Grateful for any help.

After reading all the threads online, I was very inspired to make new countertops. I have tried casting with both fine concrete and expanding concrete. I can’t say there was any difference. The idea was that you wouldn’t need to vibrate as much with expanding concrete, but I vibrated with a hammer drill with a chisel for about 30 minutes and there were still bubbles left. When you vibrate that hard, the silicone came loose and halfway entered the casting. So my tip is to take it easy with the vibrations  or skip the silicone entirely, which I did with the second slab.

or skip the silicone entirely, which I did with the second slab.

I treated the slab with sodium silicate without diluting it with water. It became sticky immediately and left streaks in what I brushed on. The surface also did not dry. After 2 days, it was still soluble with water and corrosive. Not something I would want to put my morning sandwich on. So I managed to rinse/rub everything off with protective gloves and a towel. The small concrete slab I had a 50-50 mix with water in the sodium silicate and brushed on. The result was good, it hardened but was not water-resistant for 2 seconds. Hmmm.

Now I put the slabs in the kitchen and treated them with Osmo hard wax oil (carnauba), a small can for 400 crowns. It had now been 1 week since the casting. It was allowed to dry according to the can for 1 day and then the second coat. Even then, there were streaks from the brush, and I recommend spreading it out with a cloth. After about 14 days, full curing of the wax is supposed to occur, making it resistant to scratches.

4 months later: If water sits on it for about 5-10 minutes, you can easily scrape off the entire wax layer from the slab. There have also appeared millions of bubbles underneath, which is a sign that I should have waited for more than 1 week for the curing before applying the wax.

The conclusion is that nothing has worked for me. But you want to share your mistakes

What I will do now is soak the slab for 10 minutes and remove all the wax with a towel (that's all it takes) and then apply a couple of layers of dilute sodium silicate in multiple stages to see how it reacts, and then possibly stone soap or maybe another attempt with wax.

I treated the slab with sodium silicate without diluting it with water. It became sticky immediately and left streaks in what I brushed on. The surface also did not dry. After 2 days, it was still soluble with water and corrosive. Not something I would want to put my morning sandwich on. So I managed to rinse/rub everything off with protective gloves and a towel. The small concrete slab I had a 50-50 mix with water in the sodium silicate and brushed on. The result was good, it hardened but was not water-resistant for 2 seconds. Hmmm.

Now I put the slabs in the kitchen and treated them with Osmo hard wax oil (carnauba), a small can for 400 crowns. It had now been 1 week since the casting. It was allowed to dry according to the can for 1 day and then the second coat. Even then, there were streaks from the brush, and I recommend spreading it out with a cloth. After about 14 days, full curing of the wax is supposed to occur, making it resistant to scratches.

4 months later: If water sits on it for about 5-10 minutes, you can easily scrape off the entire wax layer from the slab. There have also appeared millions of bubbles underneath, which is a sign that I should have waited for more than 1 week for the curing before applying the wax.

The conclusion is that nothing has worked for me. But you want to share your mistakes

What I will do now is soak the slab for 10 minutes and remove all the wax with a towel (that's all it takes) and then apply a couple of layers of dilute sodium silicate in multiple stages to see how it reacts, and then possibly stone soap or maybe another attempt with wax.

Last edited:

I have been tempted to cast my own plates. After reading this thread, among others, I felt very hesitant. Now I definitely don't feel like it anymore.

It's probably a matter of where you set your bar as well. For our part, it will be wooden benches as it looks now. Good luck with getting it sorted though.

It's probably a matter of where you set your bar as well. For our part, it will be wooden benches as it looks now. Good luck with getting it sorted though.

Renovation rookie

· Dalarna

· 3 173 posts

Bumping this thread a bit. When I installed mine, I said I wanted everything included. That didn't happen. He didn't do the wall. So now I'm standing there building with lightweight concrete but after trying some coloring methods (on loose blocks), I'm not satisfied.

Do you think it would look nice to cast concrete panels and attach them to the lightweight concrete blocks?

NOTE: The "masonry" is not finished in the picture. But you get an idea of how it looks. I would rather not move the stove either since it has already been tested and approved. And yes, I should have written this more clearly in the papers But you always learn something.

But you always learn something.

/Christian

Do you think it would look nice to cast concrete panels and attach them to the lightweight concrete blocks?

NOTE: The "masonry" is not finished in the picture. But you get an idea of how it looks. I would rather not move the stove either since it has already been tested and approved. And yes, I should have written this more clearly in the papers

/Christian