20,355 views ·

38 replies

20k views

38 replies

Calculate U-value for construction

Page 1 of 3

I am planning an upcoming construction and became a bit interested in the U-value for a complete wall structure (or roof). There is often talk about how important it is to avoid thermal bridges, but I rarely see any theoretical examination of how different solutions perform in comparison to each other.

Therefore, I thought I should do that (mostly for fun, but a little useful too).

Questions

1. How important is it to avoid thermal bridges?

2. If it is important, how is it best done?

3. Is there any point in insulating the installation layer?

4. Which constructions are most effective? U-value versus price or number of steps.

5. Is it true that there is an advantage with a thermally massive (large heat capacity) wall as cellulose manufacturers claim?

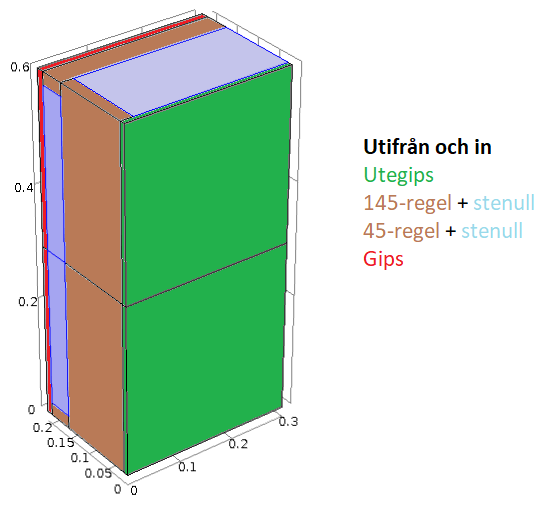

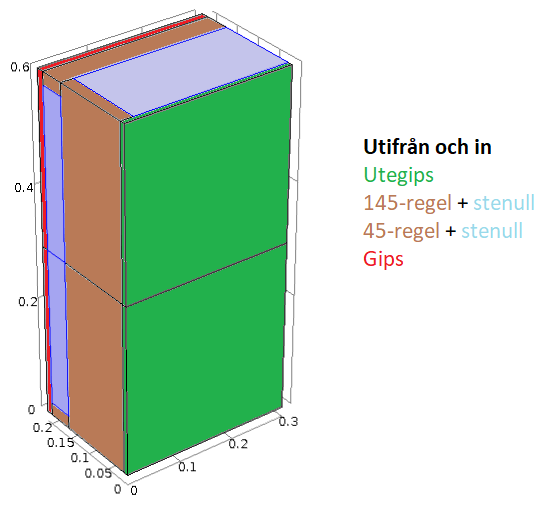

I thought I would start with a reference case, a 145 mm frame (600 cc) with outer gypsum board (9 mm) and a horizontal 45 mm stud on the inside (600 cc, insulated installation layer). Innermost is a gypsum board (13 mm). Stone wool as insulation (lambda 36).

The model looks like this:

On the inside, I assume 20 °C (convection boundary condition, h = 15 W/m^2/K) and on the outside -20 °C (h = 60 W/m^2/K). Thus, a temperature difference of 40 °C.

U-value for this construction is 0.213 W/m^2/K. Without the installation layer, the value is U = 0.278.

So what happens if I replace the stone wool in the installation layer with air? First, a check without convection (thus with air as solid): U = 0.194 W/m^2/K.

Since air has significantly lower thermal conductivity (k = 0.025 compared to k = 0.036 for stone wool), the value is expectedly lower. But if we add the assumption that the air behaves as a fluid (natural convection), we get U = 0.248 W/m^2/K.

Thus

Without installation layer: U = 0.278 W/m^2/K.

With empty installation layer: U = 0.248 W/m^2/K.

With stone wool in the installation layer: U = 0.213 W/m^2/K.

In this specific case, it is clearly profitable to put stone wool in the installation layer as there is nothing else that breaks the thermal bridge from gypsum to stud (further to outer gypsum board and then to outside air).

It might be interesting to look at how the heat flow goes through the wall. Here are two figures for the two calculations (the scale is limited to show 0 to 1 W/m^2K):

Uninsulated installation layer:

Insulated installation layer:

Over the studs:

Uninsulated installation layer: max 0.58 W/m^2

Insulated installation layer: max 0.46 W/m^2

Blue areas:

Uninsulated installation layer: around 0.22 W/m^2

Insulated installation layer: around 0.19 W/m^2

The losses are higher overall, but especially over the studs with the uninsulated installation layer.

/Anton

Therefore, I thought I should do that (mostly for fun, but a little useful too).

Questions

1. How important is it to avoid thermal bridges?

2. If it is important, how is it best done?

3. Is there any point in insulating the installation layer?

4. Which constructions are most effective? U-value versus price or number of steps.

5. Is it true that there is an advantage with a thermally massive (large heat capacity) wall as cellulose manufacturers claim?

I thought I would start with a reference case, a 145 mm frame (600 cc) with outer gypsum board (9 mm) and a horizontal 45 mm stud on the inside (600 cc, insulated installation layer). Innermost is a gypsum board (13 mm). Stone wool as insulation (lambda 36).

The model looks like this:

On the inside, I assume 20 °C (convection boundary condition, h = 15 W/m^2/K) and on the outside -20 °C (h = 60 W/m^2/K). Thus, a temperature difference of 40 °C.

U-value for this construction is 0.213 W/m^2/K. Without the installation layer, the value is U = 0.278.

So what happens if I replace the stone wool in the installation layer with air? First, a check without convection (thus with air as solid): U = 0.194 W/m^2/K.

Since air has significantly lower thermal conductivity (k = 0.025 compared to k = 0.036 for stone wool), the value is expectedly lower. But if we add the assumption that the air behaves as a fluid (natural convection), we get U = 0.248 W/m^2/K.

Thus

Without installation layer: U = 0.278 W/m^2/K.

With empty installation layer: U = 0.248 W/m^2/K.

With stone wool in the installation layer: U = 0.213 W/m^2/K.

In this specific case, it is clearly profitable to put stone wool in the installation layer as there is nothing else that breaks the thermal bridge from gypsum to stud (further to outer gypsum board and then to outside air).

It might be interesting to look at how the heat flow goes through the wall. Here are two figures for the two calculations (the scale is limited to show 0 to 1 W/m^2K):

Uninsulated installation layer:

Insulated installation layer:

Over the studs:

Uninsulated installation layer: max 0.58 W/m^2

Insulated installation layer: max 0.46 W/m^2

Blue areas:

Uninsulated installation layer: around 0.22 W/m^2

Insulated installation layer: around 0.19 W/m^2

The losses are higher overall, but especially over the studs with the uninsulated installation layer.

/Anton

Know-It-All

· Västra Götaland

· 11 967 posts

It is also interesting how the thermal bridge transfers heat from the room air itself. The thermal bridge is quite small, so how large is the spread-out cold surface on the plaster in the room?

This is an interesting discussion. Spontaneously, I don't think thermal bridges are a major problem unless a highly conductive material like concrete is involved. When it comes to thermal inertia structures, I believe it is an underdeveloped area in Sweden. There is a lot of experience to utilize here and great potential for energy savings. In countries with harsher climates than Sweden, it is almost life-threatening not to consider the heat capacity of structures.

Glad that it's appreciated!

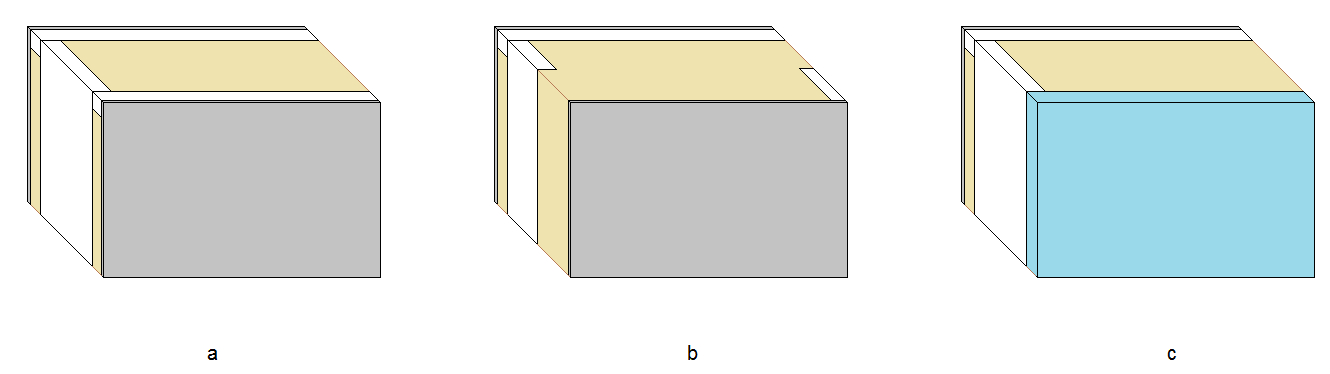

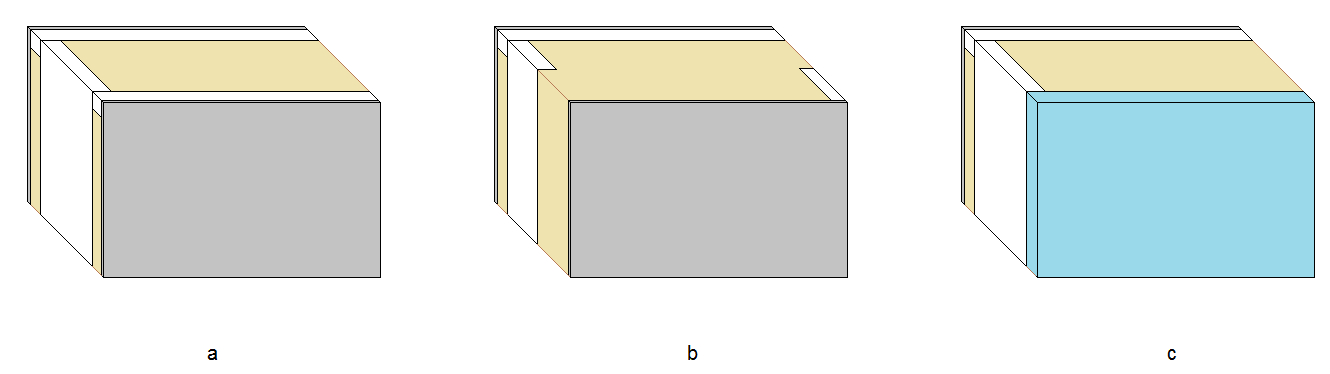

What do you think about a comparison of different solutions resulting in the same wall thickness?

a. Exterior plasterboard + 45 insulation (horizontal) + 145 insulation (vertical) + 45 insulated installation layer + plasterboard

b. Exterior plasterboard + 95 insulation (vertical) + 95 insulation (vertical) + 45 insulated installation layer + plasterboard

c. STEICOuniversal (52 mm) + 145 insulation (vertical) + 45 insulated installation layer + plasterboard

Any other solution that's interesting? Lightweight beams (like masonitebeam, swelite-beam, hunton lightweight beams)?

/Anton

I can provide a diagram showing the inside this evening.Johannes Carlsson said:

What do you think about a comparison of different solutions resulting in the same wall thickness?

a. Exterior plasterboard + 45 insulation (horizontal) + 145 insulation (vertical) + 45 insulated installation layer + plasterboard

b. Exterior plasterboard + 95 insulation (vertical) + 95 insulation (vertical) + 45 insulated installation layer + plasterboard

c. STEICOuniversal (52 mm) + 145 insulation (vertical) + 45 insulated installation layer + plasterboard

Any other solution that's interesting? Lightweight beams (like masonitebeam, swelite-beam, hunton lightweight beams)?

/Anton

Last edited:

Know-It-All

· Västra Götaland

· 11 967 posts

I find it interesting to compare light beam. It is still a thermal bridge unlike facade board.

For example, Facade board 70 + exterior gypsum +195 stud + 45 installation + OSB + gypsum

And wood fiber board +265 light beam with cellulose insulation +45 installation + sheathing + gypsum

For example, Facade board 70 + exterior gypsum +195 stud + 45 installation + OSB + gypsum

And wood fiber board +265 light beam with cellulose insulation +45 installation + sheathing + gypsum

S

swirve

Electronics enthusiast

· Östergötland

· 1 473 posts

swirve

Electronics enthusiast

- Östergötland

- 1,473 posts

Interesting! Point 5 about heat capacity would be interesting to have clarified. I live in a log house which has a fairly heat-retaining structure, which is appreciated during large temperature variations. I am planning to expand and am considering insulation materials. One factor that currently gives cellulose bonus points is its heat retention capacity, but the question is whether I've bought into the manufacturers' myth or if it really holds true.

Or maybe a board like Isover P31 (link) which has wind protection? However, glass wool (unpleasant handling IMO).Johannes Carlsson said:

Lightweight beam is interesting to compare with, I think. It is still a thermal bridge unlike facade board.

For example: Facade board 70 + exterior gypsum + 195 stud + 45 installation + OSB + gypsum

And wood fiber board + 265 lightweight beam with cellulose insulation + 45 installation + board sheathing + gypsum

Is your second suggestion like my suggestion c, but with lightweight beam? Why board sheathing?

/Anton

EDIT: Ah, facade board is also available as stone wool (link), a bit more pleasant handling, though not as good as, for example, wood fiber.

Last edited:

Know-It-All

· Västra Götaland

· 11 967 posts

Facade board with exterior gypsum used by Varbergshus

The example of raw sheathing is from XN Villa, which aims to build as ecologically as possible (less glue in raw sheathing compared to OSB)

The example of raw sheathing is from XN Villa, which aims to build as ecologically as possible (less glue in raw sheathing compared to OSB)

Okay. How did it go with your house? Interesting solution in this thread: link.Johannes Carlsson said:

Took a look at other house suppliers.

Fiskarhedenvillan:

We are building a house from fiskarhedenvillan, personally think they haven't avoided thermal bridges very well.

Götenehus:

Offset standing studs that break the thermal bridge.

Sköna hus:

Facade board to break the thermal bridge.

Suggestion from Paroc:

Both facade board and double frames (standing studs) and divided sill. Should give good values, but very many steps to build. Even better if they had offset the inner frame relative to the outer one...

/Anton

Know-It-All

· Västra Götaland

· 11 967 posts

For me, it will be a passive house from XN villa (360mm lightweight framing + 45 installation if I remember correctly) realized that it takes too much energy/time/stress to build myself.

Otherwise, I had an idea about inner 120x45 and outer 70x45, then fill any choice of the gap (235) with loose wool/cellulose. Standing on plywood that holds together at the bottom part. Only concrete under the 120 framework wall. If you need a concrete slab/beam at all. It would be exciting to build entirely without concrete and run heating via air or alternatively grooved panels. The air system is very quick to adjust the temperature (but that belongs in another thread)

Otherwise, I had an idea about inner 120x45 and outer 70x45, then fill any choice of the gap (235) with loose wool/cellulose. Standing on plywood that holds together at the bottom part. Only concrete under the 120 framework wall. If you need a concrete slab/beam at all. It would be exciting to build entirely without concrete and run heating via air or alternatively grooved panels. The air system is very quick to adjust the temperature (but that belongs in another thread)

It is quite simple to calculate the heat capacity for, for example, 1 sqm of a specific wall construction. If you multiply the specific heat of a building material by its bulk density, you get a measure of the heat capacity of a certain volume of the material. Then, you just need to calculate the volume fractions in the wall construction for each material type and multiply by the previously mentioned value and sum them up.

When I look at different types of materials under these conditions, solid wood comes out quite high, almost on par with concrete. The various types of mineral wool have similar specific heat, but stone wool, due to its higher bulk density, has significantly greater heat capacity.

A good way to utilize heat capacity is to use it as a delay so that outdoor temperature variations, between day and night, are counteracted. By placing insulating layers correctly in relation to the heat-retentive ones, you can control the delay with some precision.

When I look at different types of materials under these conditions, solid wood comes out quite high, almost on par with concrete. The various types of mineral wool have similar specific heat, but stone wool, due to its higher bulk density, has significantly greater heat capacity.

A good way to utilize heat capacity is to use it as a delay so that outdoor temperature variations, between day and night, are counteracted. By placing insulating layers correctly in relation to the heat-retentive ones, you can control the delay with some precision.

Absolutely, just phase shift in hours seems to be used as a measure for a wall construction by some manufacturers. Cellulose and wood fiber insulation also rank fairly well when you look at the numbers, at least if you pack it reasonably. Check out Steico flex, 2100 J/kg/K, 50 kg/m^3.J justusandersson said:It's quite simple to calculate the heat capacity for, for example, 1 square meter of a specific wall construction. If you multiply the specific heat of a building material by its bulk density, you get a measure of the heat capacity of a certain volume of the material. Then, it's just a matter of calculating the volume proportions in the wall construction for each material type, multiplying by the previously mentioned value, and summing up.

When I look at various types of materials with these conditions, solid wood comes up quite high, actually almost on par with concrete. The different types of mineral wool have similar specific heat, but rock wool, due to its higher bulk density, has significantly greater heat capacity.

A good way to utilize this heat capacity is to use it as a delay so that outdoor temperature variations, between day and night, are counteracted. By placing insulating layers correctly in relation to the thermally inert ones, you can control the delay with some precision.

I will try to simulate phase shift later.

/Anton

Here are figures for heat transfer from indoor air to the wall (the same two cases as before):Johannes Carlsson said:

Non-insulated installation layer:

Insulated installation layer:

When the installation layer is insulated, linear cold areas are obtained along both horizontal and vertical studs and a cold spot where they intersect.

But for the case without insulation in the installation layer, the bottom edge of each layer becomes the coldest due to air circulation in the gap. The air furthest out (towards the insulation) is cooled and falls downward to meet the horizontal stud and the gypsum board. It then warms up as it rises along the gypsum to meet the upper horizontal stud and resumes the process. There is a cold spot at the bottom by the vertical studs.

/Anton

Last edited:

Phase shift

Several manufacturers talk about "Phase shift" or phase displacement with the unit hours (h). As I understand it, they measure how long it takes for a change on one side of the wall to penetrate to the other. Specifically, by applying a sinusoidal temperature fluctuation on the outside and observing the temperature on the inside. The value is obtained by the distance from a peak (or trough) on one side of the wall to a peak (or trough) on the other side.

If we take the above case with an insulated installation layer, I get the following results.

I apply a temperature that is constant (-20 C) up to time 0 and then varies with an amplitude of 20 C:

The temperature on the inside then becomes:

The first trough is shifted by 2.6 hours and thereafter by 3 hours (both peaks and troughs). In an example from STEICO, a wall with 140 mm studs and mineral wool gets a phase shift of 5.6 hours. But they compare the temperature outside with the temperature inside, and I have calculated the temperature on the inner wall. There is, of course, also a delay before the air temperature follows suit.

/Anton

Several manufacturers talk about "Phase shift" or phase displacement with the unit hours (h). As I understand it, they measure how long it takes for a change on one side of the wall to penetrate to the other. Specifically, by applying a sinusoidal temperature fluctuation on the outside and observing the temperature on the inside. The value is obtained by the distance from a peak (or trough) on one side of the wall to a peak (or trough) on the other side.

If we take the above case with an insulated installation layer, I get the following results.

I apply a temperature that is constant (-20 C) up to time 0 and then varies with an amplitude of 20 C:

The temperature on the inside then becomes:

The first trough is shifted by 2.6 hours and thereafter by 3 hours (both peaks and troughs). In an example from STEICO, a wall with 140 mm studs and mineral wool gets a phase shift of 5.6 hours. But they compare the temperature outside with the temperature inside, and I have calculated the temperature on the inner wall. There is, of course, also a delay before the air temperature follows suit.

/Anton