5,643 views ·

29 replies

6k views

29 replies

Under-dimensioned load-bearing wall?

No. 90x270 is significantly better. You have to go up to 165x225 to find a wider but equivalent dimension.

Ok, thanks for the answer, then it will be 90x270.J justusandersson said:

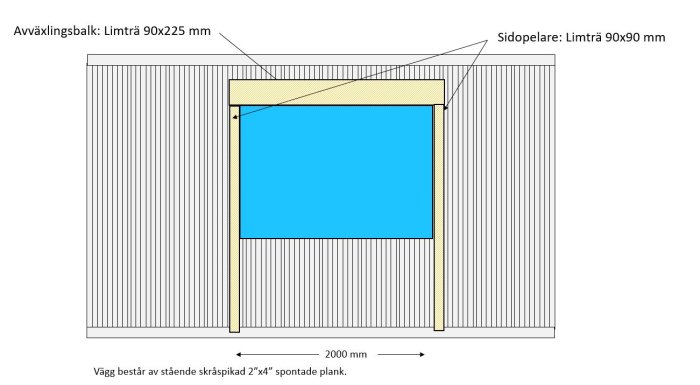

Another thought/question on the same topic. I am also going to create an opening for a window "under the same rafters". The idea was to use 90x225 glulam as a support beam and 90x90 glulam as side pillars, but that was when I thought it was a stud wall with wood shavings as insulation. But now that I've discovered the charm of plank walls, I want to make as small an intrusion as possible. So what solution do you recommend?

To open up according to the drawing and embed two 90x90 glulam beams as side pillars?

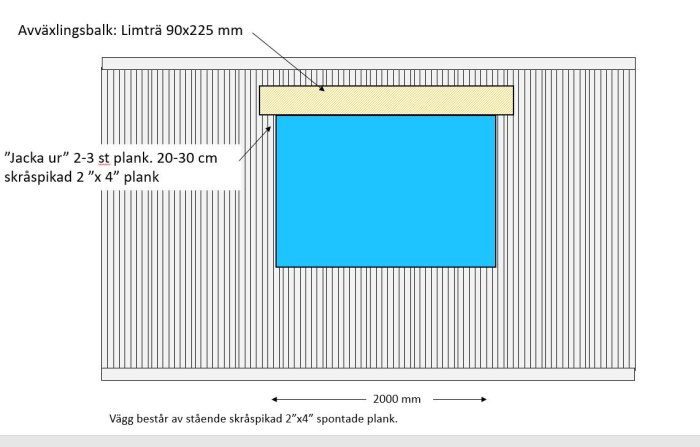

Or to "notch" into the plank wall for the load-bearing beam and let it rest on the plank wall, I think you could leave 3 planks on each side to rest on. That corresponds to about 30 cm on each side to transfer the loads.

Writing the answer on the phone so I need to be brief. The final solution is the best in principle.

I think three planks will be good.

I did exactly as you said, Justus, and despite the heavy snow on the roof, there has been 0 mm of deflection so far.J justusandersson said:

Anyway, I am about to unload and insert the new beam into the opening in the main wall that the post was originally about

But I've started to think about the side columns and their attachment. One is intended to be next to the chimney, it's a "wing" built out as the current wall goes there. So from a fire safety perspective, I'm not worried, but I doubt whether I can attach the side column to the chimney.

The other column I can attach to the main wall, so that should be fine. But the question is how I handle the side column next to the chimney? If one column is attached to the main wall, the supporting beam is fixed to this, and the beam in turn can be attached to the rafters, can't it? Then shouldn't the side column next to the chimney only take vertical forces and thus not require attachment other than between the beam/side column and side column/floor?

Make sure the pillar is locked horizontally, at the top and bottom. Do not fasten into the chimney.

Thanks, just as I thought, that's a relief. I've read many of your really great posts here and have understood that you prefer wood over steel, and perhaps especially not to mix them.J justusandersson said:

But I'm still curious to at least evaluate what dimension a steel beam (like an HEA type) would need to be to carry the same loads as the glulam beam of 90x270. It will build quite a lot simply put. It's not a disaster, but it would be nice to know what one might gain with a steel beam.

Thanks for all the help, Justus, a treasure trove!

HEA 140 corresponds to 90x270 glulam in this case. Even with cladding added, an HEA beam is significantly lower. I have nothing against steel, but especially in renovations, it can be troublesome. Moreover, it is heavy and expensive. In a new construction where you can lift in a steel beam with a crane and simplify the structure thanks to the steel, I think it is a different situation.

Thanks for the response. Then it will probably be HEA. Since I need about 2300mm, the price will be the same as buying a cut HEA140 as a 6m 90x270.J justusandersson said:HEA 140 corresponds to 90x270 glulam in this case. Even with cladding, an HEA beam is significantly lower. I don't mind steel, but especially in renovations, it can be troublesome. Additionally, it's heavy and expensive. In new constructions, when you can lift a steel beam with a crane and simplify the construction thanks to the steel, I think it's a different situation.

Can I still use 90x90 side pillars, or should I use 150x150 to match the HEA beam's "imprint" of 140mm?

Likewise, the span ensures that the weight won't be a big problem; it should weigh about 60kg.

Besides price and weight, is there any other potential complication I should consider and prevent while building?

There is a point in having the same width for beams and columns. There are many alternatives to 90x90, such as 90x135 or 140x140. From a load perspective, however, 90x90 is sufficient. Steel has greater longitudinal expansion than wood, so some allowance for movement is desirable.

I see, thanks. In the opening, there are two trusses, the next ones rest at one end on the load-bearing wall and on the other side of the opening shows a wing on the chimney. A carpenter recommended offloading from above. That is, letting the load-bearing beam run on top of the trusses' lower arms over the load-bearing wall. Fix the first trusses to the secondary beam with fork anchors. Could this be an option? I am considering a 90x270 glulam resting on the truss near the chimney (which in turn rests on the chimney) and then letting it continue over 3-4 trusses over the load-bearing wall. Then the load from the two free-hanging trusses should be transferred down via the chimney and down to the load-bearing wall via the trusses on the other side.J justusandersson said:

The advantage of this, besides the aesthetic aspect, would be simplicity. You avoid aligning pillars and fitting a beam. And you gain more space where it is needed (in the attic it doesn't matter).

I have the ceiling joists exposed in the attic for running electricity, so I can offload in more ways if needed.

Best regards,

Viktor J

Last edited:

what do you say Justus, would that be an option? I could also consider using the pillars, through the ceiling and insulation, to still support from above (if it is a suitable alternative).J justusandersson said:

Click here to reply

Similar threads

-

Bärande vägg som kompenserar vid skjutdörrar i hjärtevägg?

Planlösningar -

Noja över om kablaget i huset är för klent för nuvarande säkring.

El -

Har jag kört värmepumpen för klent?

El -

Industrial windows in the heart wall of the house

Building Physics -

Replace weak roof...

Building Materials and Construction Technology