14,769 views ·

47 replies

15k views

47 replies

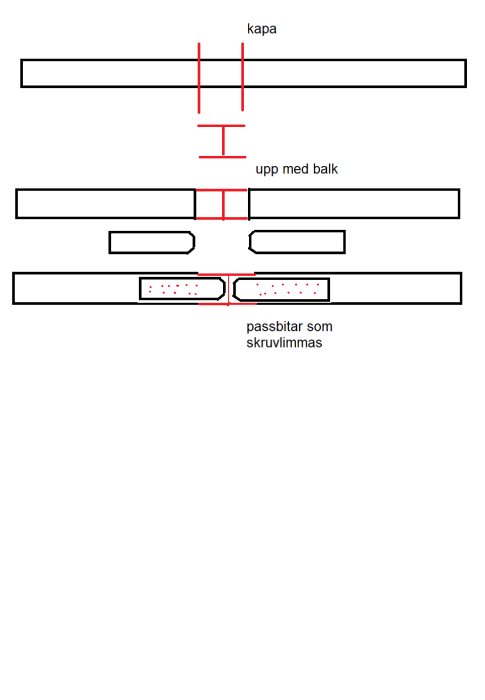

Switch floor structure with steel beam

Exactly. If you attach some plates and screw them in fairly closely in two rows, it will work wonders for the beam's Wx / Ix.Karl_Pedal said:

If you can also slightly crimp the plate lengthwise, it will be even more beneficial. This method was used on hanging trusses in an episode of Arga Snickaren if I remember correctly, which leads me to believe that the product exists precisely for that purpose.

If one is to look at alternatives, a more detailed presentation is needed. Preferably drawings, plans, and sections.

If it is only the deflection that is bothersome, would it be possible to "build away" the deflection? Otherwise, the best solution, as mentioned, is probably to shift the wall on the upper floor. Getting the sheets to work in conjunction with the existing floor structure and to gain some benefit from them is difficult. For this to work, you must push up both the floor structure and the roof before the sheets are mounted; otherwise, they are only useful for the deflection of snow load. Please attach some picture in addition to what justus wrote.

In which solution do you think the beams wouldn't need to be relieved before? Of course, they must be relieved, or alternatively pushed up, regardless of the solution. I thought that was obvious and implicit.B bossespecial said:If only the deflection is disturbing, would it be possible to "build away" the deflection? Otherwise, the best solution, as mentioned, is probably to switch the wall on the upper floor.

Getting the plates to cooperate with the existing joists and making use of them is difficult. For this to work, you must push up both the joists and the roof before the plates are installed; otherwise, they are of no use except for the deflection of snow load.

Feel free to attach some pictures in addition to what justus wrote

It is obvious to me, although perhaps not to everyone else since this wasn't really clear in the post...

Yes, it might be possible if you screw-glue on both sides of each beam. Not a bad idea at all.K Kaboff said:

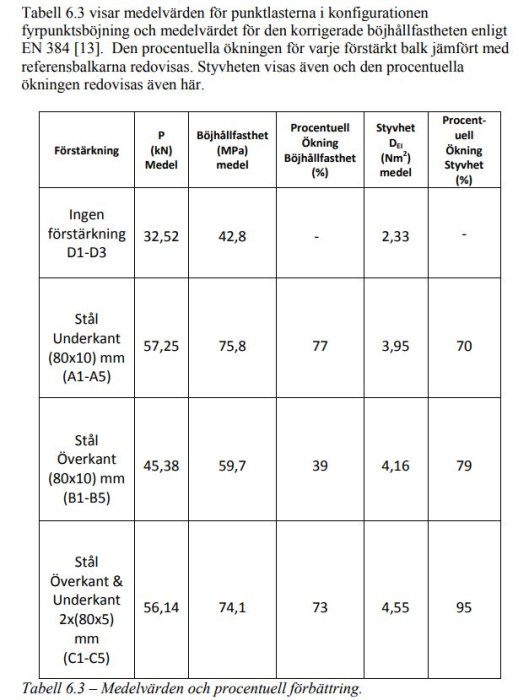

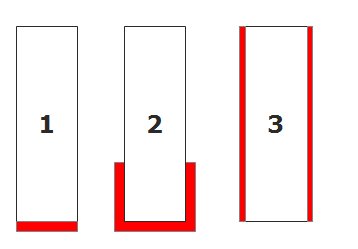

Otherwise, I have been further brainstorming about reinforcing the joists with sheets, and the question is: Which of the methods below is the most sensible to use? The reason I included steel on the underside is because it was used here: http://www.byggmek.lth.se/fileadmin/byggnadskonstruktion/publications/THID/kjellkvist_lindahl.pdf (section 1.1)

I had a similar situation and solved it by embedding a T-beam, as you said. Actually, it was two L-beams welded together. But it made the installation relatively easy, and the beams could be continuous (reinforced with tension ties).

As for after-installation, I would absolutely say option 3. If you screw tightly enough, you will probably eliminate all slenderness ratios. Option 1 is completely unacceptable, it will never work, and 2 looks complicated. It should be reasonably simple to calculate.Karl_Pedal said:

Yes, that might be possible if you use screws and glue on both sides of each beam. Not a bad idea at all.

Otherwise, I've been thinking further about reinforcing the beams with plates, and the question is: Which of the methods below makes the most sense to use? The reason I included steel at the bottom is because it was used here: [link] (section 1.1)

[image]

It certainly seems like 70% is with just steel on the underside and nothing else. The lower the steel is positioned, the more beneficial it is, but it must be very well glued to avoid sheer, but you probably already know that.K Kane said:

I skimmed the report and dismissed it as not entirely relevant since it most likely deals with factory-built beams where the steel and glulam beam are very (like extremely) integrated. I assess that one is not capable of doing this on one's own on-site.

I am fully capable of roughly calculating deflection and stress on a beam, and I would argue that a plate on the side that is glued and tightly screwed is the most reasonable and realistic. Then you can always bend the plate along its length near the ends to achieve even better results. But if you have a different opinion and expertise in the subject, just bring it on.

No no, I have no ambition to surpass the expertise in the subject. It was just your comment about 1 being "reprehensible" that I didn't agree with after glancing through the report for a moment.

(Realized over the weekend while clearing out old books in the garage that it has been a long time since going through Bengt Sundström's works.... . So the starting stretch is guaranteed to be long.)

. So the starting stretch is guaranteed to be long.)

(Realized over the weekend while clearing out old books in the garage that it has been a long time since going through Bengt Sundström's works....

It is primarily stiffness that you're after. I looked a bit more closely at the report, and it is seriously glued and screwed. Then there's glulam as well, and I'm not entirely sure how it would look on a standard 45x170? I think vertical plates are the most efficient, but that's hardly something that does itself with the removal of ceilings, etc. But it would have been fun to get an opinion from a pro.K Kane said:No, no, I have no ambition to surpass the expertise on the subject. It was just your comment that 1 was "objectionable" that I disagreed with after skimming the report for a little while.

(I realized this weekend when I was clearing out old books in the garage that it's been a long time since I delved into Bengt Sundström's works..... So the starting stretch is definitely long.)

If we proceed with option 3 being the most suitable for someone without a glulam factory - What would be the optimal hole pattern to achieve good connections without weakening the beams too much when drilling? And what screw dimension provides the right balance between absorbing shear force and material weakening?