6,626 views ·

38 replies

7k views

38 replies

Concrete mold for countertop that bulges

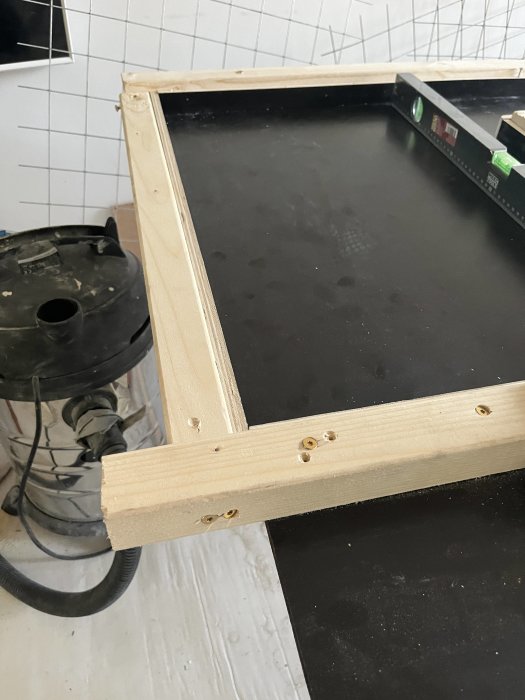

Try screwing a brace to the ply from underneath to straighten the bottom? This should be complemented with more braces before casting so it doesn't start to sag from the weight of the concrete.B billyby said:[image] [image] [image] Hi! I'm casting a kitchen countertop and was planning to cast tomorrow. But now I notice that the entire mold is bowing a bit in the middle. Does anyone have tips on how to straighten it out? The form ply was quite warped when I bought it, but the seller said it would even out when I braced it. The problem is that since the countertop is exactly 250, I've had to brace outside the ply.

Thanks for the response! How do I do that without making holes in the form itself if I screw battens from underneath? There won't be much grip if I only screw in one centimeter (the plywood is 12mm).E epw said:

Thank you! Not entirely sure about cc40. Is it 4cm between each screw? And same question as above. What screws should I use to get a good grip on the mere 12mm I have on the plywood so I don't puncture the surface I'm going to cast on?A atomlab said:

If, for example, you screw in a beam that is 45 mm, you can use a 55 mm screw and make sure not to drive it into the wood but stop just before so the plywood doesn't crack or bulge out. Cc40 means you should place beams with a 40 cm distance from the center of one beam to the center of the other. So, 35.5 cm between the beams if you use 45mm wood.B billyby said:

Thanks for the great explanation! Yes, then I really think it should be enough. I'll update tomorrow on how it goes.E epw said:If, for example, you screw a beam that is 45 mm, you can use a screw that is 55 mm and make sure not to drive it into the wood but stop just before so the plywood doesn't crack or bulge. Cc40 means that you should place beams with 40 cm from the center of one beam to the center of the other. So it's 35.5 cm between the beams if you are using 45 mm wood.

How thick will the slab be? Reinforcement?

What will you treat it with? I have used stenfix 50 with very good results, coffee or wine does not stain the slab. However, I have sanded down the slabs so you can see all the different stones, there's a thin layer of concrete that easily absorbs everything, but that's often what people perceive as the concrete look. So taste is like the backside. Regards, Anders

What will you treat it with? I have used stenfix 50 with very good results, coffee or wine does not stain the slab. However, I have sanded down the slabs so you can see all the different stones, there's a thin layer of concrete that easily absorbs everything, but that's often what people perceive as the concrete look. So taste is like the backside. Regards, Anders

Thanks for the tips! The slab will be 3cm, the plan is to lay double reinforcement at the sink/range to prevent it from cracking. I will then sand down with a wet concrete grinder to reveal the stones as you say. Therefore, I'm using coarse concrete.A Anders_sbj said:How thick will the slab be? Reinforcement?

What will you treat it with? I have used stone fix 50 with very good results, coffee or wine doesn't set into the slab. However, I have sanded down the slabs so you can see all the different stones, there's a thin layer of concrete that easily absorbs everything, but that's often what people perceive as the concrete look. So taste is like a backside. Regards Anders