4,730 views ·

27 replies

5k views

27 replies

Floor joist dimension - 5.6 meters

I am in the process of renovating an old log barn and need help with designing the new floor.

The building consists of a log upper part that sits on a fairly high stone wall/foundation. The lower part hasn't been used for anything in the past 25 years due to the poor condition of the floor (the ceiling in the "cellar").

Now I have torn out the floor (and confirmed how poor the condition actually was), and have started to consider solutions for a new floor. The logging will be getting some new logs before the floor construction begins, so I have some time to consider the floor options.

The plan is for it to become a woodworking workshop, so the floor must be sized to potentially support some older (heavier) machines.

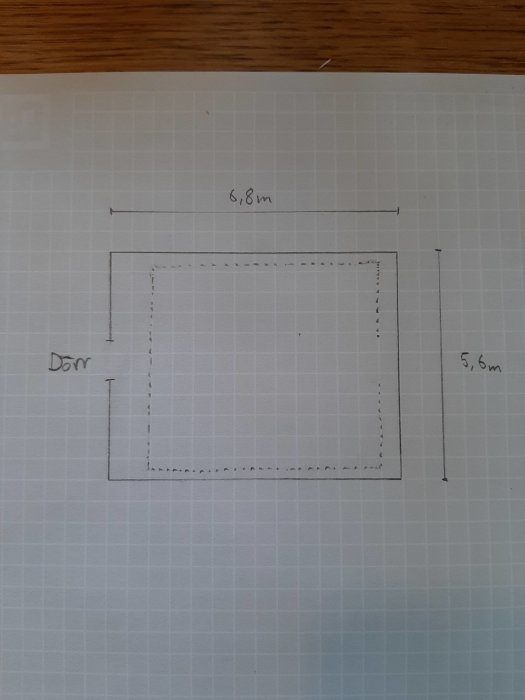

The interior dimensions are 5.6m * 6.8m. The ceiling height is generous, even with a thicker floor and possible future insulation in the ceiling.

My first thought was laminated beams across the building, i.e., 5.6 meters long, hung in the log wall with beam shoes. What dimension is needed? Should I place them at cc600 and insulate between them, or should I have joists at an angle on top to insulate between? Should I use glued tongue-and-groove flooring and then overlay flooring, or is a robust wooden floor sufficient?

The building consists of a log upper part that sits on a fairly high stone wall/foundation. The lower part hasn't been used for anything in the past 25 years due to the poor condition of the floor (the ceiling in the "cellar").

Now I have torn out the floor (and confirmed how poor the condition actually was), and have started to consider solutions for a new floor. The logging will be getting some new logs before the floor construction begins, so I have some time to consider the floor options.

The plan is for it to become a woodworking workshop, so the floor must be sized to potentially support some older (heavier) machines.

The interior dimensions are 5.6m * 6.8m. The ceiling height is generous, even with a thicker floor and possible future insulation in the ceiling.

My first thought was laminated beams across the building, i.e., 5.6 meters long, hung in the log wall with beam shoes. What dimension is needed? Should I place them at cc600 and insulate between them, or should I have joists at an angle on top to insulate between? Should I use glued tongue-and-groove flooring and then overlay flooring, or is a robust wooden floor sufficient?

Lightweight hb350 I would recommend. But glulam 90x270 also works. This is for residential load. Designing for potentially freely placed 1-ton machines is difficult. The safest is if you can have a load-bearing core wall underneath.

What are the advantages of a lightweight I-beam over glulam? I have no experience with them at all.J JKrister said:

Sure, 1-ton machines will obviously be difficult, and I understand that I won't be able to place just anything in the workshop. Thinking at least it might be smart to dimension up from residential loads?

Regarding the heart wall, it would probably be possible, but right now there's not even a floor to speak of in the basement. I've removed a very decayed wooden floor there, and underneath it's just soil. Would a longitudinal bearing beam with several posts be an alternative to a heart wall?

A quick sketch where the dashed line represents the approximate inner wall of the stone foundation. A heart wall would end up right in the doorway (right short side on the sketch) for the basement, hence my question about posts instead.

Yes, if one can halve any span, switching to regular K-wood, such as 45x220, would be possible. This would be much cheaper. A beam on pillars is probably the easiest solution and it doesn’t matter which direction. It also doesn't need to be in the middle but can be placed along Emma's doorpost. This way, the spans can be divided into 2.3m and 3.3m.

I’m only on mobile, but the size of the beam and the pillars would depend on how many foundations one is willing to make. Had we had a stable foundation, one could have constructed a 45x120 wall cc600 and skipped the beam.

I like the light beams as I often work alone. A much lighter beam in terms of weight. Strangely enough, fewer places stock them.

I’m only on mobile, but the size of the beam and the pillars would depend on how many foundations one is willing to make. Had we had a stable foundation, one could have constructed a 45x120 wall cc600 and skipped the beam.

I like the light beams as I often work alone. A much lighter beam in terms of weight. Strangely enough, fewer places stock them.

Getting away with k-lumber would definitely be nice. I have no knowledge at all about pouring foundations, but I'll have to do some research on the subject.J JKrister said:Yes, if you can halve any span, you can switch to regular k-lumber. Like 45x220. Which would be much cheaper. A beam on posts is probably the easiest solution and it doesn't matter in which direction. It also wouldn't have to be in the middle but can be placed alongside Emma's doorpost. And in this way divide the span into 2.3m and 3.3m.

I'm just on my phone, but the size of the beam and posts will be a balance between how many foundations you're willing to make. If we had a solid ground, you could have framed a 45x120 wall with cc600 and skipped the beam.

I like the lightweight beams because I often work alone. A much lighter beam in terms of weight. Strangely enough, fewer places stock them.

Could you, or any other kind soul here on the forum, calculate the dimensions for the posts and beam? An arbitrary number of posts, I don't know myself what is reasonable.

Yes, it wasn't so easy to find price information for the lightweight beams, they do sound convenient to handle alone.

Thank you so much for the helpful answers.

With 3 posts, i.e., 4 compartments and basement walls, we get a span of 1700mm. A glulam beam 56x270 is needed as a load-bearing beam and 45x195 as a floor joist. I would probably go for double 45x220 as a load-bearing beam and 45x220 in the floor joist. Posts in 90x90 glulam if the basement is going to be heated. Unheated, 95x95 tr. imp. should work fine and can be cast directly unless it's very wet in the ground.

I wouldn't use joist hangers but would try to notch into the log wall and run the floor joist beams in a bit. It's very easy to assume that screws have anchored into old timber, but then it turns out it's just tinder. A screw pulls out easily compared to pressing a 45x220 down into the timber.

The same goes for the load-bearing beam. If there is headroom, place the load-bearing beam underneath. Especially we happy amateurs. Screw connections are often a weak link and provide no warning. The screw snaps, and then everything collapses. Wood on wood gives a little warning, bends, flexes.

I wouldn't use joist hangers but would try to notch into the log wall and run the floor joist beams in a bit. It's very easy to assume that screws have anchored into old timber, but then it turns out it's just tinder. A screw pulls out easily compared to pressing a 45x220 down into the timber.

The same goes for the load-bearing beam. If there is headroom, place the load-bearing beam underneath. Especially we happy amateurs. Screw connections are often a weak link and provide no warning. The screw snaps, and then everything collapses. Wood on wood gives a little warning, bends, flexes.

I agree that lightweight beams are underrated, especially when there is plenty of vertical space. In this case, however, I am somewhat doubtful. Instead, I would suggest a system of glulam bearer beams, e.g., 90x405 (several alternative dimensions available) at c/c 1800 mm. On top of that 45x220 C 24 c/c 600. For flooring, I would choose real floorboards (28-30 mm thick). They provide a much better feel when standing and working. Such a floor structure, designed for a useful load of 3 kN/sqm, can also handle point loads of 1000 kg to a moderate extent.

Are the beams in this proposal intended to be longitudinal or transverse?J justusandersson said:I agree that lightweight beams are underrated, especially when you have plenty of space in height. In this case, however, I am somewhat hesitant. I would instead suggest a system of glulam beams, e.g., 90x405 (there are several alternative dimensions) on c/c 1800 mm. On top of that 45x220 C 24 c/c 600. For flooring, I would choose real floorboards (28-30 mm thick). They provide a much better feel when you stand and work. Such a floor structure, designed for a load of 3 kN/sqm, can also handle point loads of 1000 kg to a moderate extent.

What do you think of the previous proposal with posts? I know I mentioned that the ceiling height is generous, but a floor that builds 405+220+30 plus insulation in the ceiling might still result in a bit too low ceiling height near the long sides.

What makes you hesitant about lightweight beams in this case? Just curious, I have no personal knowledge of them.

Thanks for the tips regarding joist hangers, I hadn't considered that aspect that you don't get any warning. Regarding the logging, some logs on the long sides will be replaced anyway, so I feel fairly secure about screwing into them, but it's definitely something I should keep in mind.J JKrister said:With 3 posts, i.e., 4 compartments and basement walls, we get a span of 1700mm. Then a glulam beam 56x270 is needed as a support beam and 45x195 as the joist. I would probably go for double 45x220 as the support beam and 45x220 in the joists. Post in 90x90 glulam if the basement is supposed to be heated. Unheated, 95x95 pressure-treated wood should work fine and can be poured directly if it's not very wet in the ground.

I wouldn't use joist hangers but try notching into the log wall and inserting the joist beams a bit inwards. Very easy to think a screw has fastened in old timber but then it turns out it's just rotted. A screw pulls out easily compared to pressing a 45x220 down into the timber.

The same goes for the support beam. If there's headroom, place the support beam underneath. Especially we happy amateurs. Screwed connections are often a weak link and give no warning. The screw snaps off, and then everything crashes. Wood on wood gives a little warning, bends, and flexes.

Regarding the example with the posts, I had planned a construction more like the heart wall we talked about. That is, a longitudinal support beam supported by several posts, and then construction timber across it at 600mm centers.

The basement will be unheated.

B Barriospurer58 said:Thanks for the tips regarding the joist hangers, I hadn't thought about that aspect of not getting any warning. Regarding the timbering, some logs will be replaced on the long sides anyway, so I feel pretty confident about screwing into them, but it's definitely something I'll keep in mind.

Regarding the example with the posts, I was thinking of a construction more similar to the heart wall we talked about. That is, a longitudinal bearing beam supported by multiple posts, and then construction timber across it at cc600.

The basement will be unheated.

Yes, if it's a new log to attach the beam to, then joist hangers should be fine. But at the same time, it's very easy to notch out for 45x220 before you even put the log in place.

The bearer beams in my proposal are transverse, i.e., 5 pcs. 90x405. 90x405 can be replaced by 140x360 or 190x315. Posts under the bearer beams are very wise and significantly reduce the dimensions. High live loads and high point loads, I think, make a solution with glulam + construction timber better.

Okay! And with a post in the middle under each beam, what would the dimension be then?J justusandersson said:

With a post under each load-bearing beam, you end up with modest dimensions, 90x225.