47,640 views ·

31 replies

48k views

31 replies

Deck in non-treated wood, crazy?

Tool enthusiast

· Stockholm

· 268 posts

I have built with kärnfuru! It was heavy = Resin and hartch rich! Protects itself then!

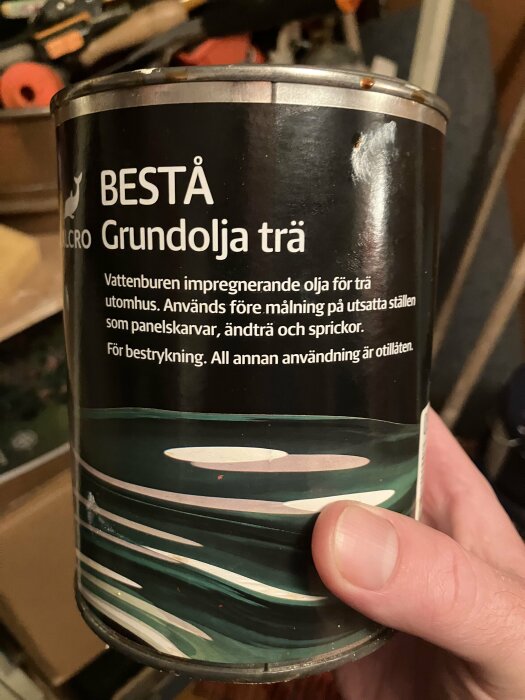

It has grayed nicely! With a little oil and possibly a silicon treatment, it will last a long time.

It has grayed nicely! With a little oil and possibly a silicon treatment, it will last a long time.

One might question whether it is environmentally better to oil every year compared to pressure-treated wood. Pressure-treated wood contains metal salts that are essentially non-toxic to humans in the amounts that might leak out, and largely they remain in the wood throughout the construction's lifespan. However, oiling means that aromatic hydrocarbons are spread in the environment, which are not completely harmless.

In practice, both methods are probably almost completely harmless to the user. How bad it is for the environment at large is likely primarily determined by how the pressure-treated wood is handled the day it needs to be demolished.

In practice, both methods are probably almost completely harmless to the user. How bad it is for the environment at large is likely primarily determined by how the pressure-treated wood is handled the day it needs to be demolished.

It is not possible to discuss impregnated versus non-impregnated wood without considering timber quality and execution. The difference between what is available in the market in southern Sweden and in Norrland is enormous. Dense northern Swedish pine with a high content of heartwood holds up better than pressure-impregnated fast-grown timber that can be bought in Skåne. Regardless of quality, wood exposed to weather must be installed in such a way that water runs off. Dense timber holds its shape better and results in less "cupping." Wood that comes into contact with soil must either be pressure-impregnated of class A or kärnek.

My pressure-treated wooden decks are now 18 years old and hopefully will last another 10 years. I believe the material was of higher quality.

On the other hand, I have larch in the windows (seems ok) and in the boarding around the windows, and the latter are really of poorer quality. Additionally, they are as dry as tinder, soak up the oil like a sponge, and turn completely black when oiled.

The most interesting question is how to obtain high quality when replacement is needed. Not at the building supply stores.

On the other hand, I have larch in the windows (seems ok) and in the boarding around the windows, and the latter are really of poorer quality. Additionally, they are as dry as tinder, soak up the oil like a sponge, and turn completely black when oiled.

The most interesting question is how to obtain high quality when replacement is needed. Not at the building supply stores.

Or is it the frame itself that is non-pressure treated wood. The beams that I will place 60 cc are pressure treated. It lies directly on the ground with stone slabs in between. Quite dry where the sun deck will be, as we have sun on the site almost all afternoon/evening. I can get a picture tomorrow 😀Jonatan79 said:

A few years ago, I tore down a constructed deck that was built solely with non-impregnated rough-sawn wood. It had only been painted a few times over the years. It stood for over 20 years, but when it was demolished, it was completely worn out, in some places rotten through.

Lay down sill paper on top that extends a few cm on either side so they are protected from water from above and should last a long time.B Bongoloid said: