656 views ·

2 replies

656 views

2 replies

How much can you mill down a concrete slab without risks?

Hi. I have a room on the 3rd floor that has a very uneven floor and it needs to be leveled with self-leveling compound. The old compound needs to be ground down so that a new top layer can be added with a thickness of 1-10 mm. The problem is that the floor (made of 20 cm thick precast concrete) is so uneven that you would need to grind down about 1.5 cm into the actual concrete at one end of the room to be able to apply the new top layer without issues. The house was built in the late 70s with concrete elements (assembled with the same precision as a Mamma Mu-cabin).

So... should I just go ahead with the diamond grinder and grind down the concrete about 1.5 cm? Raising the floor isn't really a good option because it would create issues with the door and the floor outside in the corridor.

So... should I just go ahead with the diamond grinder and grind down the concrete about 1.5 cm? Raising the floor isn't really a good option because it would create issues with the door and the floor outside in the corridor.

If it's just for the heights that you need to mill, then it's probably fine to go ahead. If I weren't on vacation, I could use the computer to calculate it. But if you don't have problems with the level difference, then just go ahead and apply on the existing layer.M mattie_river said:Hello. I have a room on the 3rd floor that has a very uneven floor and it needs to be leveled with self-leveling compound. The old self-leveling needs to be milled down so that a new top layer can be applied with a thickness of 1-10 mm. The problem is that the floor (built of 20 cm thick prefabricated concrete slabs) is so uneven that you'd need to mill down about 1.5 cm into the concrete itself on one end of the room to be able to apply the top layer without issues. The house was built in the late '70s with concrete elements (assembled with the same precision as a Mamma Mu treehouse).

So... is it just a matter of going at it with a diamond grinder and removing about 1.5 cm of concrete? Raising the floor isn't really an option because it would cause issues with the door and the floor in the corridor outside.

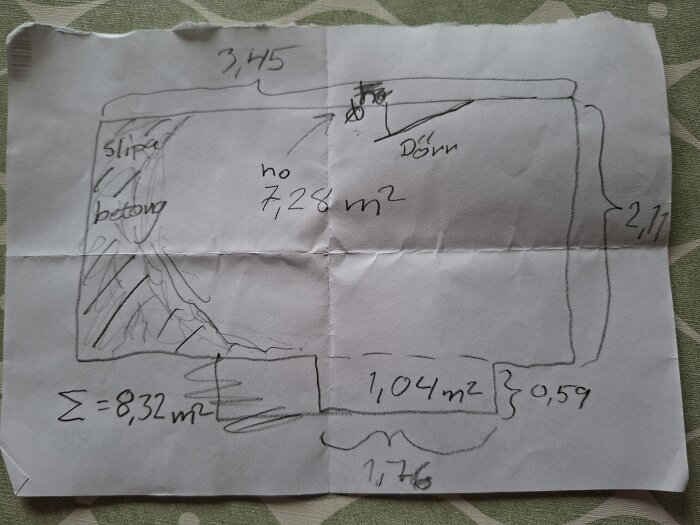

It's the hatched area on the left that needs to be lower. That area is closest to the load-bearing wall the floor level is on. The entire span of the level is about 5.2 meters. Let's put it this way - if one were to sand the concrete to make it a visible floor, you would probably need to take 1 - 1.5 cm to "sand through" all the pits and unevenness. I'm a bit unsure, but it might be that they poured concrete on a prefabricated element when they built. I think the top is very uneven to be factory-made. (The door is - of course - where the floor is the lowest...)F Fjonken said:

Last edited:

Click here to reply

Similar threads

-

Tillåtet att fräsa ner kabelrör i betonggolv i BRF?

Bostadsrätt -

Fräsa ventilation i innerdörrar?

Ventilation -

Milling down water pipes into slab and routing it through edge beam?

Building Materials and Construction Technology -

Hyvla/fräsa ner tröskel?

Golv -

Hjälp - skadad gräsmattan efter dränering. Fräsa upp eller inte?

Gräsmatta