21,385 views ·

24 replies

21k views

24 replies

What can and cannot be built? (loose timber)

Now I (or we actually) am planning actively. The goal is a timber-frame house that we will enjoy, have the nice features we might appreciate, and preferably look somewhat cool (i.e., the wishes most people have). But the reason for the thread then... Yes, now I want what I plan and draw to be possible to build and preferably with a reasonable effort and cost. So, good and viable solutions.

So I start the thread with a question now, but I will add completely different thoughts as time goes on. Then I think the thread can be open for anyone with construction considerations that fit here, to post their own questions, if they don’t want to start their own threads.

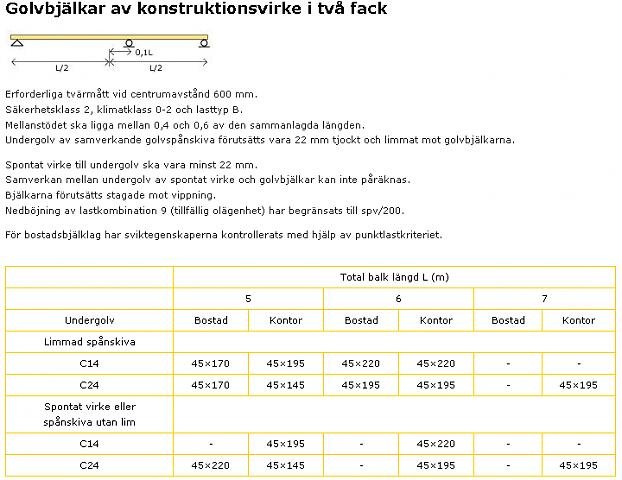

OK, then I'll start with something that I’m a bit curious about. On the Wood Guide’s website, you find an attached table for floor joists with a load-bearing (heart) wall as support in the middle.

In this table, it looks like the maximum house width will be somewhere around 6-7 meters. But I don’t think that can be right, because "everyone's" catalog houses have models with 8 meters (often) and sometimes up to 10 meters.

What’s wrong? Is the Wood Guide's table too careful and conservative, or are the house manufacturers using wood from those carbon fiber pines I've heard about (in the future... )

)

edit: and then the picture with ....

So I start the thread with a question now, but I will add completely different thoughts as time goes on. Then I think the thread can be open for anyone with construction considerations that fit here, to post their own questions, if they don’t want to start their own threads.

OK, then I'll start with something that I’m a bit curious about. On the Wood Guide’s website, you find an attached table for floor joists with a load-bearing (heart) wall as support in the middle.

In this table, it looks like the maximum house width will be somewhere around 6-7 meters. But I don’t think that can be right, because "everyone's" catalog houses have models with 8 meters (often) and sometimes up to 10 meters.

What’s wrong? Is the Wood Guide's table too careful and conservative, or are the house manufacturers using wood from those carbon fiber pines I've heard about (in the future...

edit: and then the picture with ....

Hi Mikael_L

I believe that list is per maximum length in a section, i.e., if you have an intermediate floor that is 11 meters wide, you would need to divide it into 2 parts, one that is 7 meters and one that is 4m, for example, depending on where the load-bearing walls are located on the ground floor.

Best regards, Jawen

I believe that list is per maximum length in a section, i.e., if you have an intermediate floor that is 11 meters wide, you would need to divide it into 2 parts, one that is 7 meters and one that is 4m, for example, depending on where the load-bearing walls are located on the ground floor.

Best regards, Jawen

One can also achieve longer spans by combining regular beams with transverse glulam or steel beams. It does not need to be thicker for that. The beams can be recessed into the floor structure.

That it's possible to lay the intermediate floor over 9 meters, with a central heart wall, I understand; there are probably hundreds of catalogue houses proving that. What surprised me was this table from the wood guide.

Or is it that catalogue house manufacturers go up to 270 and even 300mm in dimension on the beams, or start using obscure kerto beams or glulam beams. Or maybe, as the home tinkerer suggests, insert additional support beams in the form of glulam beams invisibly within the floor structure.

Anyone know?

Or is it that catalogue house manufacturers go up to 270 and even 300mm in dimension on the beams, or start using obscure kerto beams or glulam beams. Or maybe, as the home tinkerer suggests, insert additional support beams in the form of glulam beams invisibly within the floor structure.

Anyone know?

I must admit that I also can't make sense of what the table refers to. For example, in BKR there is no designation for timber strength that matches C14 or 24. (It's probably some designation for chipboard?) Timber strength begins with K.

If there's just a beam (in one piece or spliced directly over the central support) as the sketch shows (on three supports), it's unlikely that the specified dimensions will hold for the given spans if you consider the deflection/bending as determining factors as the authors did. And it's also stated + that they've increased the deflection requirement to L/200. (Normally L/400.) That is, for a span of, say, 4 meters, a maximum deflection between the supports of 1 cm is normally allowed. With the table's conditions, they've halved it to 0.5 cm.

But of course, it's possible to build wider houses than 7 meters without transverse stiffeners in the floor joists. A support in the middle (or as close to it as possible) gives 4.5 meters in span on each side of the central support for a 9-meter-wide house (internal dimensions minus 2x5 cm for the supports). A span of 4.5 m and a cc distance of 60 cm is not unreasonable, provided you don't then set higher demands on deflection than normal (at maximum load, which is rarely utilized to 100%), i.e., 11.25 mm in the beam alone.

But... if you construct the floor joists with sheathing, you can account for the thickness (usually 22 mm chipboard flooring) meaning that the neutral layer moves up when considering cooperation. (Then you recalculate the section (beam + 60 cm 22 mm chipboard) using Steiner's theorem to a new bending resistance.) And of course, the sheathing should be screw- or nail-glued to the beams.

You can also reduce the cc distance between the beams to decrease the load area/beam, which then stresses each beam less.

Furthermore, you can experiment with the timber quality and choose the highest possible if the obtained bending resistance is insufficient.

It is only when these three possibilities have been fully exploited that other measures may be needed. Kerto beams have been mentioned. (Box beams are light and strong.) Even the Marsonite building system with I-beams where the flanges are wood and the web is made of hard wood fiberboard can be an alternative. If that's not enough, you can increase the load-bearing capacity of the beams with other measures. For example, stress rods. Even switching to materials with higher allowable stress (read: steel) can be a possibility.

There is therefore nothing preventing the thread creator from freely designing as wide a building body as possible (within reasonable limits). The constructor can, in most cases, handle the load-bearing capacity without major issues. Pure utopias are harder to satisfy. Like a very wide building body without a load-bearing interior wall, beam, and column, etc. But even that is possible. It all depends on the conditions given to the constructor.

_____________________

Byggaren

If there's just a beam (in one piece or spliced directly over the central support) as the sketch shows (on three supports), it's unlikely that the specified dimensions will hold for the given spans if you consider the deflection/bending as determining factors as the authors did. And it's also stated + that they've increased the deflection requirement to L/200. (Normally L/400.) That is, for a span of, say, 4 meters, a maximum deflection between the supports of 1 cm is normally allowed. With the table's conditions, they've halved it to 0.5 cm.

But of course, it's possible to build wider houses than 7 meters without transverse stiffeners in the floor joists. A support in the middle (or as close to it as possible) gives 4.5 meters in span on each side of the central support for a 9-meter-wide house (internal dimensions minus 2x5 cm for the supports). A span of 4.5 m and a cc distance of 60 cm is not unreasonable, provided you don't then set higher demands on deflection than normal (at maximum load, which is rarely utilized to 100%), i.e., 11.25 mm in the beam alone.

But... if you construct the floor joists with sheathing, you can account for the thickness (usually 22 mm chipboard flooring) meaning that the neutral layer moves up when considering cooperation. (Then you recalculate the section (beam + 60 cm 22 mm chipboard) using Steiner's theorem to a new bending resistance.) And of course, the sheathing should be screw- or nail-glued to the beams.

You can also reduce the cc distance between the beams to decrease the load area/beam, which then stresses each beam less.

Furthermore, you can experiment with the timber quality and choose the highest possible if the obtained bending resistance is insufficient.

It is only when these three possibilities have been fully exploited that other measures may be needed. Kerto beams have been mentioned. (Box beams are light and strong.) Even the Marsonite building system with I-beams where the flanges are wood and the web is made of hard wood fiberboard can be an alternative. If that's not enough, you can increase the load-bearing capacity of the beams with other measures. For example, stress rods. Even switching to materials with higher allowable stress (read: steel) can be a possibility.

There is therefore nothing preventing the thread creator from freely designing as wide a building body as possible (within reasonable limits). The constructor can, in most cases, handle the load-bearing capacity without major issues. Pure utopias are harder to satisfy. Like a very wide building body without a load-bearing interior wall, beam, and column, etc. But even that is possible. It all depends on the conditions given to the constructor.

_____________________

Byggaren

Our single-story house with a flat roof (4-degree slope) and boat shed have no load-bearing internal walls, beams, or columns. We have kertobalkar (why are they obscure, Mikael?), the longest being 11 meters. The internal walls are telescopic walls to handle snow load deflection. The price for all the kertobalkar was 76,000 SEK, but the building area for the house is 235 sqm and for the boat shed 50 sqm. Not too terribly expensive, I think, considering the cost of the entire house. Very satisfied, the house is "moderately cool" as Mikael seeks.

Apparently, they are transitioning to C-classification instead. Basically the same thing, but replacing "K" with "C", and in some cases, the number is slightly different too. See:imported_Byggaren said:

http://www.sp.se/sv/about/press/releases/Sidor/Press20061228.aspx

especially under the last heading.

No, I used the wrong word, unconventional beams is probably what I mean more, kind of...Hemmakatten said:Our single-story house with a flat roof (4-degree slope) and boathouse have no load-bearing interior walls, beams, or columns. We have kertobalks (why are they obscure Mikael?), the longest are 11 meters. The interior walls are telescopic walls to handle deflection from snow loads. The price for all the kertobalks was 76,000:-, but the building area of the residence is 235 sqm, and the boathouse is 50 sqm. Not too expensive, I think, considering the cost of the entire house. Very satisfied, the house is that "moderately cool" that Mikael is looking for.

But just today I have been in contact with swelite about masonite beams, or maybe they are also called lightweight beams, so apparently, I'm not so afraid of unconventional items after all...

What are telescopic walls?

Do you have a website or something? Where one can see what your house looks like, and maybe also during the construction time?

It would be nice to get inspired by a moderately cool house...

I looked at the building plans from a friend's construction. The measurements of the house outside = 8.9 meters, the intermediate floor hangs on beam shoes and is in laminated timber dimension 42x225. So the span should be around 8.3 meters then.

Bearing central wall in the middle.

However, the upper floor is more like a sleeping loft, with only about 1/2 meter to the ceiling at the outer wall and about 38° roof angle. I don't know if that affects how one calculates load and bearing capacity and deflection.

By telescopic walls, I mean interior walls that are not connected to the ceiling, but there is a gap of a couple of centimeters between the ceiling and the wall. This is to handle snow loads. It probably has another name in technical terms, but I'm quite sure the carpenters used the same expression.

I don't have a website, but I'm attaching a couple of pictures.

I don't have a website, but I'm attaching a couple of pictures.

So in the winter, the gap becomes smaller when the snow lies and puts pressure?Hemmakatten said:

If I understood correctly.

Aha! Now I understand. But that means the National Board of Housing, Building and Planning is behind in their standards. There are no C classifications to be seen as far as I know, unless they have updated BKR in recent days.jon_h said:

More and higher classes according to the link, writes SP. Hmm... maybe new timber then too? From where? Structural timber is usually spruce. More or less knotty. The only completely knot-free wood we have in Sweden is pine, and only the heartwood. It is likely to become 'dört' in the future to build houses with it

_______________

Byggaren

Okidoki.

Then I'll continue with the next question in the same vein.

Building a balcony on top of another part of the house is often called a risk construction.

Yet many house manufacturers build houses with this. See the images from Myresjöhus and Floods trähus.

The question is, how do you secure this type of construction?

Then I'll continue with the next question in the same vein.

Building a balcony on top of another part of the house is often called a risk construction.

Yet many house manufacturers build houses with this. See the images from Myresjöhus and Floods trähus.

The question is, how do you secure this type of construction?