5,719 views ·

17 replies

6k views

17 replies

Ventilation pipes through 220 mm rafters, load-bearing capacity maintained?

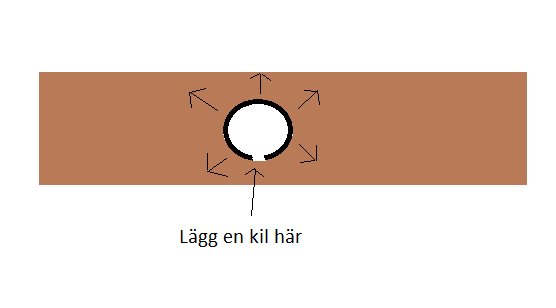

It would be pleasant to drill through multiple rafters to install ventilation pipes of 100 mm. The question is whether this affects the rafter enough for it to be impacted by this? Half of the material disappears in one place, leaving it 6 cm "thick" above and below. It becomes like a Grevé cheese...

Can you drill 105 and insert an iron ring or something?

Or no problem?

Can you drill 105 and insert an iron ring or something?

Or no problem?

Removing half of the roof truss can never be a good idea. Even though a lot was over-dimensioned in the past, it can't withstand such large alterations. Either you need to reinforce the truss or you have to find another way to route the pipe.

Member

· Etelä Pohjanmaa

· 2 467 posts

You can't imagine reducing the ventilation pipe to 80mm?

In theory, you could take a piece of a DN80 steel pipe and slit it, i.e., cut away about 8-10 mm along the length. Then make a hole in the roof truss that is a few mm smaller than the outer diameter of the steel pipe. Then compress the pipe enough so that it can be tapped into the hole. Then expand the pipe so that the force is evenly distributed around it. It shouldn't become much weaker that way.

In theory, you could take a piece of a DN80 steel pipe and slit it, i.e., cut away about 8-10 mm along the length. Then make a hole in the roof truss that is a few mm smaller than the outer diameter of the steel pipe. Then compress the pipe enough so that it can be tapped into the hole. Then expand the pipe so that the force is evenly distributed around it. It shouldn't become much weaker that way.

Finndjävel: What forces do you imagine the ring should absorb? I don't see it being of any use.

Member

· Etelä Pohjanmaa

· 2 467 posts

No, it is not. The tree compensates for the branch when it grows. But a dried branch does not add any load-bearing capacity on its own.

The underframe of a truss primarily takes tensile loads, that ring does not help at all in that situation.

The underframe of a truss primarily takes tensile loads, that ring does not help at all in that situation.

Member

· Västernorrland

· 11 696 posts

It probably also depends a lot on other conditions; a house likely won't collapse just because you drill holes if there are other walls that the rafters rest on and are attached to, but if they are free-standing rafters, you might be tempting fate. If you absolutely have to do it, then I would probably fasten 50mm flat bar above and below that extends a meter perhaps, so you get some anchoring points. Maybe even on both sides and use through bolts and nuts.

That ring that was mentioned is, as stated, of no use whatsoever. The load on the rafter is, as already mentioned, a tensile load from the walls.

That ring that was mentioned is, as stated, of no use whatsoever. The load on the rafter is, as already mentioned, a tensile load from the walls.

THANK YOU for the input. The consensus is that too much material is being removed. Reinforcement cannot go over or under, as the ceiling and floor are flush. However, one could place two beams, one below and one above, that are as high as the remaining material, like 45*45. Or drill smaller holes and multiple pipes as useless suggests. The ring will be tricky. If a ring, it should be hammered in with force to counteract compression? Like a church tower.

Member

· Etelä Pohjanmaa

· 2 467 posts

You don't need a beam to handle the tensile load either, do you? A regular board is enough. Did you think that the outer walls and snow weight would create such a large tensile load that the beam would be pulled apart in the middle? It's probably more the deflection that's countered if you insert a pipe. The pipe corresponds to a fresh branch, not a dry one.

Those look more like they are sized as floor joists. As mentioned, it's primarily deflection that is the determining factor.

Member

· Etelä Pohjanmaa

· 2 467 posts