1,265 views ·

6 replies

1k views

6 replies

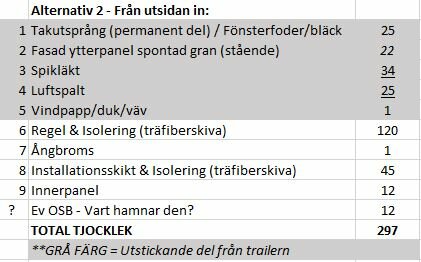

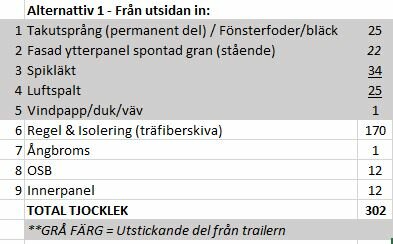

Two different wall constructions - for self-supporting construction

I have come up with two different options for wall construction.

It's for a tiny house that will be on a trailer and therefore must be self-supporting. It's also important that the construction doesn't become much thicker.

Anyway, do these walls have the potential (together with the frame and roof structure) to form a self-supporting construction?

Which one would you choose and why, or any changes? Feedback on moisture, etc., is also of interest.

Share your thoughts and suggestions! It is appreciated

It's for a tiny house that will be on a trailer and therefore must be self-supporting. It's also important that the construction doesn't become much thicker.

Anyway, do these walls have the potential (together with the frame and roof structure) to form a self-supporting construction?

Which one would you choose and why, or any changes? Feedback on moisture, etc., is also of interest.

Share your thoughts and suggestions! It is appreciated

Not 100% sure, but trailer manufacturers and engineers have used these terms. I interpret it to mean that the construction should not rely on the trailer but "support itself," though I'd love a more detailed/simple explanation of the termViolina said:

Then it is probably more about needing it to be stable and not relying on the sill having full support then...

It's probably more about how you build the wall (think truss and sandwich) than the order of the different materials in the wall.

It's probably more about how you build the wall (think truss and sandwich) than the order of the different materials in the wall.

Hello,

I assume that by self-supporting it means that the wall should bear the load for the roof structure, but I'm not entirely sure if this is what is meant by self-supporting.

Option 2 is preferable if the stud dimension is sufficient for the loads it is subjected to. It depends on the span of the roof as well as the snow and wind zone where the house will be located. Option 2 has an interior installation layer where you can run installations if you wish, and the vapor barrier is placed further inside, reducing the risk of puncturing it when screwing into the wall. I would guess the OSB would be placed inside the inner panel in Option 2, as it isn't very attractive to have on the surface.

I assume that by self-supporting it means that the wall should bear the load for the roof structure, but I'm not entirely sure if this is what is meant by self-supporting.

Option 2 is preferable if the stud dimension is sufficient for the loads it is subjected to. It depends on the span of the roof as well as the snow and wind zone where the house will be located. Option 2 has an interior installation layer where you can run installations if you wish, and the vapor barrier is placed further inside, reducing the risk of puncturing it when screwing into the wall. I would guess the OSB would be placed inside the inner panel in Option 2, as it isn't very attractive to have on the surface.

I would definitely consider working with sheet material instead of panels as a surface layer. They are both lighter and allow for thinner construction. Are there any environmental requirements involved, i.e., that it should be built sustainably? Otherwise, I would use PIR insulation. The wall loads on a trailer become quite low as the house will be fairly long and narrow, so the roof area to be supported is low.

Since the house is so small, installation layers in the wall are hardly needed; wiring can be routed in the floor and ceiling.

I would construct the wall as follows from the outside, all boards screwed and glued.

-Grooved plywood 9-12mm

-Air gap 12mm

-C24 stud with intervening PIR insulation 95mm

-Tongued PIR approx. 20mm

-Grooved plywood 9-12mm

Total wall thickness approx. 150mm with insulation performance equivalent to 200mm of regular insulation. The weight is about 20kg/m2.

Since the house is so small, installation layers in the wall are hardly needed; wiring can be routed in the floor and ceiling.

I would construct the wall as follows from the outside, all boards screwed and glued.

-Grooved plywood 9-12mm

-Air gap 12mm

-C24 stud with intervening PIR insulation 95mm

-Tongued PIR approx. 20mm

-Grooved plywood 9-12mm

Total wall thickness approx. 150mm with insulation performance equivalent to 200mm of regular insulation. The weight is about 20kg/m2.

Click here to reply

Similar threads

-

Söker LED-strålkastare med olika färger

Belysning -

1970-talshus i sju olika skepnader

Artikelkommentarer -

Uppdelat eller ihop? - Två olika sorters hus

Övrigt husrelaterat -

8 sagolika hus med torn – från slottsromantik till 2020-tal

Artikelkommentarer -

U-värde för olika äldre väggkonstruktioner

Isolering