I've read some threads and hope to get some thoughts and feedback on my attempts to build my first staircase.

Conditions:

Straight staircase to a mezzanine

One stringer against the wall for mounting

Incline about 40 degrees

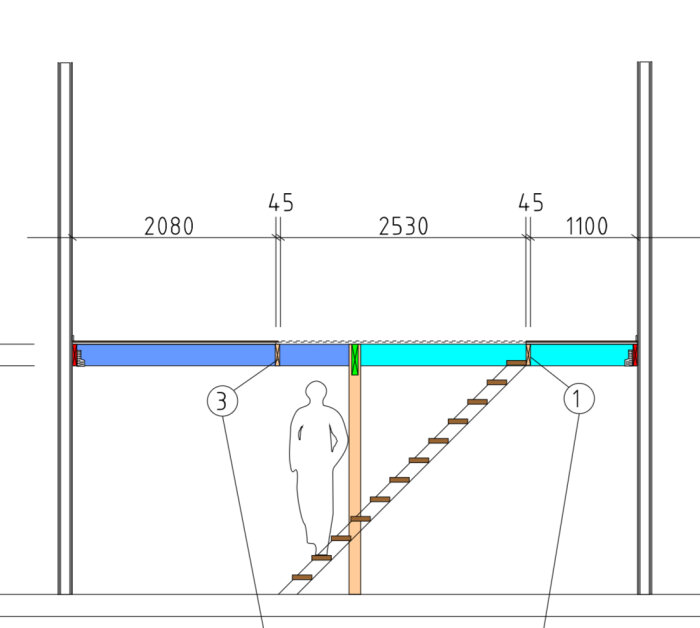

With a smaller angle (less than 40 degrees) you risk hitting your head after a few steps. The picture only shows measurements and a roughly sketched staircase.

Thoughts on material:

Stringer: 42x270 mm laminated wood

Steps: 42x270 mm laminated wood

The idea is to route the steps into the stringer, screw + glue. Inexperienced router user, but considering a template in OSB/MDF, test routing. Screw the template in place before each routing. Staircase in utility area, so aesthetics are not a priority, although it would be nice if it looked good.

Routing depth? 15 mm too little?

Step height: about 18 cm

Hard to find good material for the steps, don't want to tongue and groove - hence the choice of 42x270. Are the steps too thick or heavy? Is the step depth okay?

Laminated wood for the stringer to minimize twisting. Cheaper with 45x220 regular timber but thinking 270 gives more possibility for mounting? Also, easier with just one material to bring home.

Conditions:

Straight staircase to a mezzanine

One stringer against the wall for mounting

Incline about 40 degrees

With a smaller angle (less than 40 degrees) you risk hitting your head after a few steps. The picture only shows measurements and a roughly sketched staircase.

Thoughts on material:

Stringer: 42x270 mm laminated wood

Steps: 42x270 mm laminated wood

The idea is to route the steps into the stringer, screw + glue. Inexperienced router user, but considering a template in OSB/MDF, test routing. Screw the template in place before each routing. Staircase in utility area, so aesthetics are not a priority, although it would be nice if it looked good.

Routing depth? 15 mm too little?

Step height: about 18 cm

Hard to find good material for the steps, don't want to tongue and groove - hence the choice of 42x270. Are the steps too thick or heavy? Is the step depth okay?

Laminated wood for the stringer to minimize twisting. Cheaper with 45x220 regular timber but thinking 270 gives more possibility for mounting? Also, easier with just one material to bring home.

Novissnickare said:

Read a bit in threads and hope to get some thoughts and feedback on my attempts to build my first staircase.

Conditions:

Straight staircase to a mezzanine level

One stringer against the wall for attachment

Incline about 40 degrees

At a smaller angle (less than 40 degrees), you risk hitting your head after a few steps. The picture only shows dimensions and roughly sketched staircase.

Thoughts on materials:

Stringer: 42x270 mm glulam

Steps: 42x270 mm glulam

The idea is to rout the steps into the stringer, screw+glue. Inexperienced router, but thinking template in osb/mdf, test routing. Screw the template in place before each routing. Stairs in a rough space, so aesthetics not a priority, though it would be nice if it could look good.

Routing depth? 15 mm too little?

Step height: about 18 cm

Difficult to find good material for steps, don't want to tongue/groove - hence the choice of 42x270. Are the steps too thick? Step depth okay?

Glulam for stringer to minimize twisting. Cheaper with 45x220 timber, but thinking 270 offers more attachment possibilities? Also easier with just one material to bring home.

Clear

Nicely done! It looks simply great. I might take on a similar project, so I have many questionsNovissnickare said:

Yes, I followed the plan by routing grooves, gluing, and screwing.lyckograbben said:

Nice job! It looks simply good. I might take on a similar project, so I have many questionsDid you follow your plan according to the first post? Any tips now after you've built it? Is it sturdy without creaks?

It might need a railing to prevent small children from crawling through or getting their heads stuck; there is a maximum allowed gap size in staircases.

[link]

Lessons learned:

Hard to achieve good slope, step height, and step depth. Spent a lot of time testing slope with string and angle measure. Had to compromise and create a landing at the top to decrease the slope to the final 37.5 degrees. Do not underestimate this step!

Take time to make a good template with sturdy material. I used a thick plastic board (about 4mm thick). Practiced on scrap pieces beforehand. Ideally, fixate by screwing the template during each routing. I screwed into the previous groove which is then covered by the step (except for the first step). Sometimes reinforced with a clamp, but often in the way of the hand router.

Tricky to "mirror" the diagonal pattern to the other stringer. Drove small short pins into the drawn pattern, lifted over the other stringer and tapped down to "copy" the pattern. Filled in with pencil. Maybe I went too far for an easy solution?

Routed grooves about 12 mm deep, sufficient, but it requires maintaining the same distance throughout and that the stringer doesn't bulge in the middle.

Chose to assemble on-site: screwed the first stringer to the wall, aligned the opposite side using two steps. Original plan to assemble everything on the ground and screw the steps from the sides was abandoned due to the staircase's total weight.

Glued in the grooves, tapped in each step, and toe-screwed at the back of the step, seems to be nearly creak-free so far—knock on wood...

Click here to reply

Similar threads

-

Tips on spiral staircase that can be customized – or combined spiral/straight?

Building Materials and Construction Technology -

Vad kostar en trapphiss, till en rak trappa?

Övrigt husrelaterat -

Hur beräknas bärförmåga på limträbalk som sticker ut från fasad?

Lösvirke & Timmerhus -

Help to calculate the dimension of glulam beam immediately.

Building Materials and Construction Technology -

Bör man betala bostadsmäklarens trappa provision innan kontraktskrivn

Juridik