18,406 views ·

15 replies

18k views

15 replies

Soundproofing in interior walls - what will be the perceived reduction?

Hello,

I am currently planning the renovation of the upper floor and therefore need to build new walls for the bedroom, etc. Since I grew up in an 80s kit house without any consideration for soundproofing, it has left its mark. - It is very important for me that it becomes "quiet."

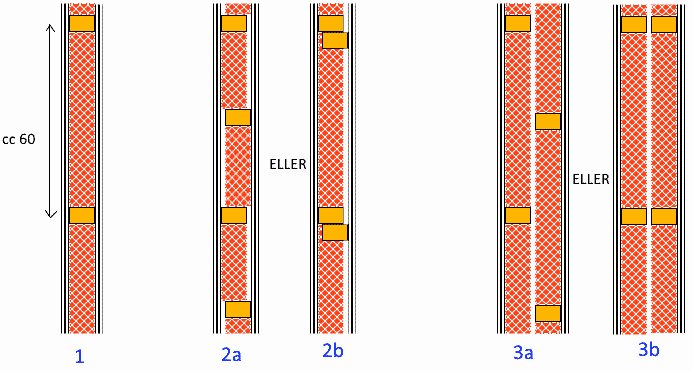

I understand that there are a number of construction techniques, but I haven't fully understood if, for example, you build according to image 2a or 2b? The insulation doesn't come in cc25? With which option do you achieve, for example, when watching TV at a "normal" volume level, that you hear something but it's unidentifiable what is being said/heard versus "completely quiet"? We are thinking of having OSB+gypsum, but if it is the case that there is a significant advantage with gypsum+gypsum, we might consider that instead. How big of a difference does, for example, 45x70 studs make compared to 45x90? In the image, it is 70.

I am currently planning the renovation of the upper floor and therefore need to build new walls for the bedroom, etc. Since I grew up in an 80s kit house without any consideration for soundproofing, it has left its mark. - It is very important for me that it becomes "quiet."

I understand that there are a number of construction techniques, but I haven't fully understood if, for example, you build according to image 2a or 2b? The insulation doesn't come in cc25? With which option do you achieve, for example, when watching TV at a "normal" volume level, that you hear something but it's unidentifiable what is being said/heard versus "completely quiet"? We are thinking of having OSB+gypsum, but if it is the case that there is a significant advantage with gypsum+gypsum, we might consider that instead. How big of a difference does, for example, 45x70 studs make compared to 45x90? In the image, it is 70.

Hello!

I have redone some walls in our apartment and also some walls in our summer house. You can get very far with what you describe as option 1. If your wall has, from one side to the other, plasterboard-OSB-insulation/stud-OSB-plasterboard, the sound is significantly dampened according to my experience.

I "spiced up" two walls in our apartment by also adding lump paper between the OSB and the plasterboard. I don't know if it makes much difference, but I think that the more material transitions the sound has to pass through, the more it is dampened (classic physics). It cost very little and didn't actually take any extra time. You could also place lump paper on the studs before the OSB to get yet another material transition.

You also have to consider what kind of door you have. A cardboard door won't do; you need a solid wooden door.

Regarding 45x70 versus 45x90, there will naturally be some effect, partly because they are more stable studs (more mass for the sound to overcome) but also because it results in thicker insulation (again more mass for the sound to overcome).

I'm pondering whether you might get the most effect by instead turning down the sound on your TV and ensuring that there is a lot of material in the room that can absorb the sound spreading in the room (rugs, curtains, etc.), but that's not what you asked about, so we can let that answer be omitted. ;-)

Not much of a direct answer to your question, but hopefully, this helps further your thoughts a bit. Good luck!

I have redone some walls in our apartment and also some walls in our summer house. You can get very far with what you describe as option 1. If your wall has, from one side to the other, plasterboard-OSB-insulation/stud-OSB-plasterboard, the sound is significantly dampened according to my experience.

I "spiced up" two walls in our apartment by also adding lump paper between the OSB and the plasterboard. I don't know if it makes much difference, but I think that the more material transitions the sound has to pass through, the more it is dampened (classic physics). It cost very little and didn't actually take any extra time. You could also place lump paper on the studs before the OSB to get yet another material transition.

You also have to consider what kind of door you have. A cardboard door won't do; you need a solid wooden door.

Regarding 45x70 versus 45x90, there will naturally be some effect, partly because they are more stable studs (more mass for the sound to overcome) but also because it results in thicker insulation (again more mass for the sound to overcome).

I'm pondering whether you might get the most effect by instead turning down the sound on your TV and ensuring that there is a lot of material in the room that can absorb the sound spreading in the room (rugs, curtains, etc.), but that's not what you asked about, so we can let that answer be omitted. ;-)

Not much of a direct answer to your question, but hopefully, this helps further your thoughts a bit. Good luck!

Thanks for the input!

Yes, I'm aware of the door issue, and I'll tackle that later on. It would be interesting to hear if anyone has tried option 2 or 3 to know if the difference is significant enough that they felt it was worth it compared to option 1.

We have a bedroom wall like option 1, but with a poor door without a threshold, so it's not a fair comparison. However, I thought I might try bringing in a mattress and placing it in front. Then someone on the other side can turn up the TV volume.

Yes, I'm aware of the door issue, and I'll tackle that later on. It would be interesting to hear if anyone has tried option 2 or 3 to know if the difference is significant enough that they felt it was worth it compared to option 1.

We have a bedroom wall like option 1, but with a poor door without a threshold, so it's not a fair comparison. However, I thought I might try bringing in a mattress and placing it in front. Then someone on the other side can turn up the TV volume.

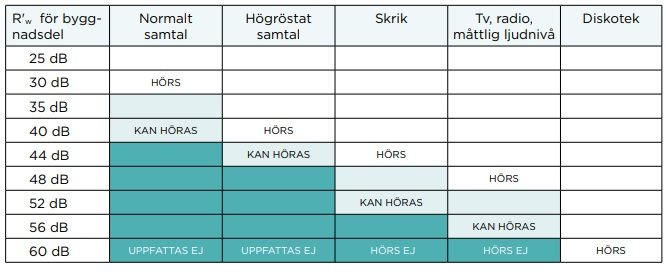

Aha, the Gyproc page was very good I think in combination with the table above, thank you.

unfortunately didn't find the combination with triple plasterboard on 70regel and insulation. When you make with air gap, the walls become very thick, alternatively use their acoustic profile, but it seemed quite cumbersome to mount.

unfortunately didn't find the combination with triple plasterboard on 70regel and insulation. When you make with air gap, the walls become very thick, alternatively use their acoustic profile, but it seemed quite cumbersome to mount.

I have built all non-load-bearing interior walls in the basement (with noisy rooms such as a workshop, playroom, laundry room, garage, etc.) according to model 2a, which I believe should reduce noise by about 50dB, but if there are other pathways for the sound to travel, the extra dampening in the walls becomes a bit unnecessary, everything must be sealed.

It's important that sound doesn't travel from room to room via the ceiling, which is often just single drywall with open spaces between the rooms above the joists. With double drywall or, as I have done, plywood + drywall, it gets a little better.

What I find to be the most challenging pathway to seal is through the doors. If you don't have a door designed to dampen sound, a lot will go through them. I've noticed that it's very advantageous to have a passage room between two rooms, which greatly improves sound dampening. For example, in our bedroom with completely undampened walls (wood panels + drywall on both sides but no stone wool, then regular doors with sealing strips except at the threshold), but you must pass through our "walk through closet" to get to it, making it reasonable to sleep even if there are people talking in the living room (you can't really hear what people are saying, although you can hear that people are talking), so good doors or buffer rooms around the ones you want to seal are more important than the walls. The downside is that soundproof doors are so expensive that it's not a realistic option if you need too many (you can, however, buy cheaper used ones).

One problem that arises with soundproof doors is that ventilation doesn’t work if you seal the door since air should enter via the bedroom and exit via the bathroom through the interior doors in the house, so you need to arrange alternative paths for the air to flow to avoid poor air quality, and these pathways should also be soundproofed.

It's important that sound doesn't travel from room to room via the ceiling, which is often just single drywall with open spaces between the rooms above the joists. With double drywall or, as I have done, plywood + drywall, it gets a little better.

What I find to be the most challenging pathway to seal is through the doors. If you don't have a door designed to dampen sound, a lot will go through them. I've noticed that it's very advantageous to have a passage room between two rooms, which greatly improves sound dampening. For example, in our bedroom with completely undampened walls (wood panels + drywall on both sides but no stone wool, then regular doors with sealing strips except at the threshold), but you must pass through our "walk through closet" to get to it, making it reasonable to sleep even if there are people talking in the living room (you can't really hear what people are saying, although you can hear that people are talking), so good doors or buffer rooms around the ones you want to seal are more important than the walls. The downside is that soundproof doors are so expensive that it's not a realistic option if you need too many (you can, however, buy cheaper used ones).

One problem that arises with soundproof doors is that ventilation doesn’t work if you seal the door since air should enter via the bedroom and exit via the bathroom through the interior doors in the house, so you need to arrange alternative paths for the air to flow to avoid poor air quality, and these pathways should also be soundproofed.

Last edited:

thanks! If you did according to alt 2a, how wide is the air gap you have? Are you using 70-studs and 70-rockwool? How do you keep them from "slumping" like an "S"? Or does that not happen?rickardg said:

I have built all non-load-bearing interior walls in the basement (with noisy rooms such as workshop, playroom, laundry room, garage, etc.) according to model 2a, which I believe dampens about 50dB, but if there are other paths for the sound to travel, the extra damping in the walls becomes a bit unnecessary, you have to seal everything.

The trick is to ensure the sound doesn't travel from room to room through the ceiling, which is often just single plasterboard with open air between the rooms above. With double plasterboard or, as I've done with plywood + plasterboard, it gets a bit better.

What I find the hardest to seal is through the doors. If you don't have a door designed to dampen noise, a lot goes through them. I've noted that it's very advantageous to have a passage room between two rooms, providing much better soundproofing, such as in the bedroom, which has completely uninsulated walls (raw timber + plasterboard on both sides but no rockwool, then regular doors but with a sealing strip except at the threshold). However, you must pass through our "walk through closet" (wardrobe) to get to it, making it reasonable to sleep even if people are talking in the living room (you can't really hear what people are saying even if you hear that people are talking), so good doors or buffer rooms around those you want to seal are more important than the walls. The downside is, though, that soundproof doors are so expensive that it's not a realistic option if you need too many (you can, however, buy cheaper second-hand ones).

One problem that arises with soundproof doors is that ventilation doesn't work if you seal the door, as air should come in through the bedroom and exit through the bathroom via the interior doors in the house. So, you must arrange alternative paths for the air to travel to prevent poor air quality, and those paths should also be soundproofed.

How did you handle the thickness of the door frames, since the standard widths don't fit, I assume? If you're building a double wall like alt 3, which might end up around 21cm, how do you handle the door frame then?

Regarding ventilation, I have an FTX and will convert the adjacent room into a closet where the rooms will share the door to the rest of the house. However, I currently have an air supply in that room, so I'll see if I'm up to rerouting the ducts in the attic. If not, it will become a sound-insulated air transfer device. I'm also looking for really good soundproof doors; does anyone have tips on those?

I built a frame with 95 studs and 70 studs inside the wall, creating a 25mm air gap.

The stone wool should be of the right density (I can't recall the exact density but it's quite heavy) for optimal soundproofing, and it doesn't compress like fiberglass. It's held in place between the studs under slight tension, but it's not completely perfect, sometimes leaving a small air gap on both sides when the insulation doesn't sit entirely on one side, but I assume this is not super critical.

I installed the doors offset towards the hinge side, screwed with frame screws, and filled the gap between the frame and the wall, then added a painted (trim?) strip of a suitable thickness to match the wall level. With a thicker wall, I would probably have used a pre-painted MDF board intended for window trim.

As I also have an FTX system, I've used two exhaust vents connected with a silencer to balance the airflow between rooms with soundproofing.

The stone wool should be of the right density (I can't recall the exact density but it's quite heavy) for optimal soundproofing, and it doesn't compress like fiberglass. It's held in place between the studs under slight tension, but it's not completely perfect, sometimes leaving a small air gap on both sides when the insulation doesn't sit entirely on one side, but I assume this is not super critical.

I installed the doors offset towards the hinge side, screwed with frame screws, and filled the gap between the frame and the wall, then added a painted (trim?) strip of a suitable thickness to match the wall level. With a thicker wall, I would probably have used a pre-painted MDF board intended for window trim.

As I also have an FTX system, I've used two exhaust vents connected with a silencer to balance the airflow between rooms with soundproofing.

Aha! Did you then alternate the studs to one side and the other like a 2x2, so the rock wool also alternated against each side of the wall? Would that be in 30cm on center, I assume? Did you cut the rock wool yourself, or did you find a size that fit? Or 90 perhaps, so it's 45cm between each stud?rickardg said:

I used a frame of 95 studs and 70 studs inside the wall, creating a 25mm air gap.

The rock wool should be of the right density (I don't remember which density, but quite heavy) for optimal soundproofing, and it doesn't sag like fiberglass wool. It sits slightly in tension between the studs, keeping it in place. However, it's not entirely perfect, so there may be a little air gap on both sides when the insulation is not fully against one side, but I guess that's not super critical.

I installed the doors shifted towards the hinge side, screwed with frame screws, and filled the gap between the frame and the wall, then I added a painted (trimpiece?) strip thick enough to be flush with the wall. With a thicker wall, I would probably have used pre-painted MDF board intended for window reveals.

Since I also have FTX, I used two exhaust vents connected with a sound damper to balance the airflow between rooms with soundproofing.

What do you mean by "shifted towards the hinge side"?

What do you think about adding a layer of OSB as well, either on the inside or as a middle layer?

I probably put all the rock wool on one side because the instructions I followed said so and it's the most practical since it's easiest to push it all the way down when the wall is open on one side.

Yes, 30cm CC, cut the rock wool myself

Since the door frame is about 95mm and the wall is 120mm, I set the door frame level with the plaster on one wall, and that will be the side where the hinges protrude. Then it'll be a 25mm trim on the other side, and door casing on both sides as usual. If you don't do that, the door leaf will crush the casing if you open the door more than 90 degrees.

Yes, 30cm CC, cut the rock wool myself

Since the door frame is about 95mm and the wall is 120mm, I set the door frame level with the plaster on one wall, and that will be the side where the hinges protrude. Then it'll be a 25mm trim on the other side, and door casing on both sides as usual. If you don't do that, the door leaf will crush the casing if you open the door more than 90 degrees.

Have various outlets on both sides, drilled through the beams in the ceiling to get into the joists sometimes and made a notch in the top beam to get pipes into the glesen. In some cases, I have a pipe sideways and drilled through the vertical studs.

I have all pipes as rigid VP pipes and try to run them in the middle of the wall as much as possible to protect them from screws. I have cut notches in the insulation for boxes, then I remember that I usually cut a groove halfway through the insulation where the pipes run, it's a bit different with different walls, sometimes I have probably nailed the pipes to the vertical studs and just let the insulation compress a bit more in the corner where the pipes end up, problems are solved on-site when they arise, tends to be many special cases all the time when building :-/

The main purpose of the insulation is probably to kill sound bouncing around in the wall, so even if it's not perfectly covering, it becomes good enough, especially if you don't have 50dB soundproof doors, then fine-tuning the insulation will likely be negligible.

I have all pipes as rigid VP pipes and try to run them in the middle of the wall as much as possible to protect them from screws. I have cut notches in the insulation for boxes, then I remember that I usually cut a groove halfway through the insulation where the pipes run, it's a bit different with different walls, sometimes I have probably nailed the pipes to the vertical studs and just let the insulation compress a bit more in the corner where the pipes end up, problems are solved on-site when they arise, tends to be many special cases all the time when building :-/

The main purpose of the insulation is probably to kill sound bouncing around in the wall, so even if it's not perfectly covering, it becomes good enough, especially if you don't have 50dB soundproof doors, then fine-tuning the insulation will likely be negligible.