About a year ago, we changed our facade. At the same time, we replaced window sills, facade flashing, and bargeboard flashings in different rounds. The sheets were replaced in two rounds. Typical sheet metal with an aluzinc-like color/coating.

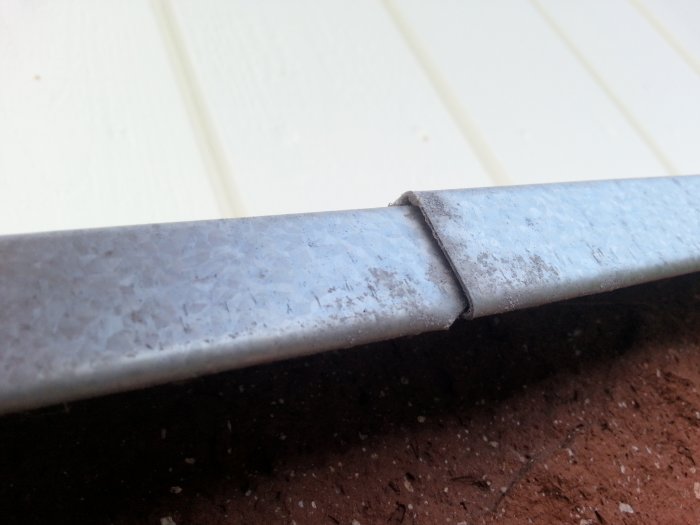

Already after a few months, the sheets replaced in the first round started to look somewhat shabby. It looks like they've been subjected to mechanical wear. It's not even across the board. It's worst at the joints and bends.

The ones installed in the second round look significantly better.

I'm in discussions with the tinsmith who isn't particularly eager to fix the problem. He claims that all the sheet metal comes from the same roll.

The only difference I can think of is that the sheets that look shabby are placed under the panel, which was painted after the sheets were installed. The final coat was done with Demidekk Ultimate. There were also sawdust particles on the sheets, which I brushed off with a soft car brush and wiped off gently with a terry towel/microfiber cloth. It seems very strange that this would affect them.

I live somewhat close to the sea, but as mentioned, the sheets most exposed to weather, the bargeboard flashings, still look fine.

Not a huge amount of money, but I am nevertheless irritated and, of course, don't feel like paying for the same thing twice. Painting on a peeling surface is not something I am keen on.

Does anyone have input/experience with something similar?

Already after a few months, the sheets replaced in the first round started to look somewhat shabby. It looks like they've been subjected to mechanical wear. It's not even across the board. It's worst at the joints and bends.

The ones installed in the second round look significantly better.

I'm in discussions with the tinsmith who isn't particularly eager to fix the problem. He claims that all the sheet metal comes from the same roll.

The only difference I can think of is that the sheets that look shabby are placed under the panel, which was painted after the sheets were installed. The final coat was done with Demidekk Ultimate. There were also sawdust particles on the sheets, which I brushed off with a soft car brush and wiped off gently with a terry towel/microfiber cloth. It seems very strange that this would affect them.

I live somewhat close to the sea, but as mentioned, the sheets most exposed to weather, the bargeboard flashings, still look fine.

Not a huge amount of money, but I am nevertheless irritated and, of course, don't feel like paying for the same thing twice. Painting on a peeling surface is not something I am keen on.

Does anyone have input/experience with something similar?

Member

· västragötaland

· 1 555 posts

Picture of the plåten would help.

Member

· västragötaland

· 1 555 posts

Aluzinc sheet metal is known for having this specific problem and many others. Aluzinc does not have a warranty on appearance but only guarantees that "the material will not be perforated by through-corrosion, which can lead to leakage." Hopefully, the sheet metal worker will take responsibility and replace it, but probably all the sheet metal you have in Aluzinc will become like that over time.

Thank you Johan for the feedback... even though it wasn't such pleasant news.

I would be grateful if others who have similar problems could upload pictures and indicate how long the sheets have been up. It might be good ammunition against my sheet metal worker who seems to think that I've made something up.

I would be grateful if others who have similar problems could upload pictures and indicate how long the sheets have been up. It might be good ammunition against my sheet metal worker who seems to think that I've made something up.

But if the surface material is zinc, it is not colorfast in that way! Newly zinc-coated surfaces are shiny but gradually become duller; eventually, they are completely matte, with various "spotty" stages in between. If the metal sheet does not have an additional surface layer to keep it shiny, it will become matte.

Member

· västragötaland

· 1 555 posts

You have this thread on the forum about aluzink:nameloser said:

http://www.byggahus.se/forum/tak-vi...lat-eller-aluzink-fordelar-och-nackdelar.html

Click here to reply

Similar threads

-

Stenplattor, stort mellanrum och olika färg

Trädgård allmänt -

Färg som släpper på plåtdetaljer

Tak & Vind -

Etsande grundfärg/primer för förzinkad plåt

Färg, Måla & Tapetsera -

Missfärgade markstenplattor

Altan & Uteplats -

Underhållsfri fibercementplatta tappar färgen producent vill måla dem

Färg, Måla & Tapetsera