5,162 views ·

9 replies

5k views

9 replies

Right frame screw for hollow brick?

Hello,

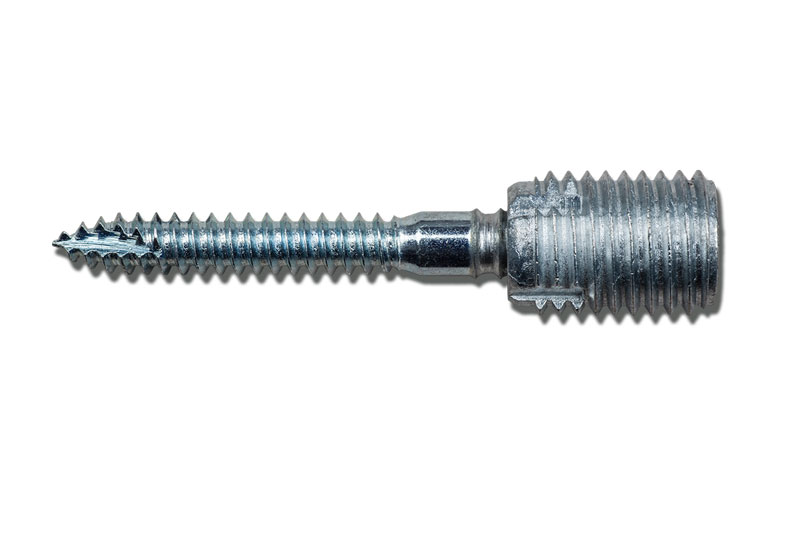

I am going to install a couple of interior doors in a basement with hollow block/lightweight concrete. Previously, I have used traditional longer hinge screws with matching plugs:

However, in all cases, I have had trouble getting them to hold firmly, so in some cases, I have had to drill additional anchor points, and in one case, I even had to use foam sealant.

Previous doors are mounted with nails in wooden pieces that have been inserted into the stone.

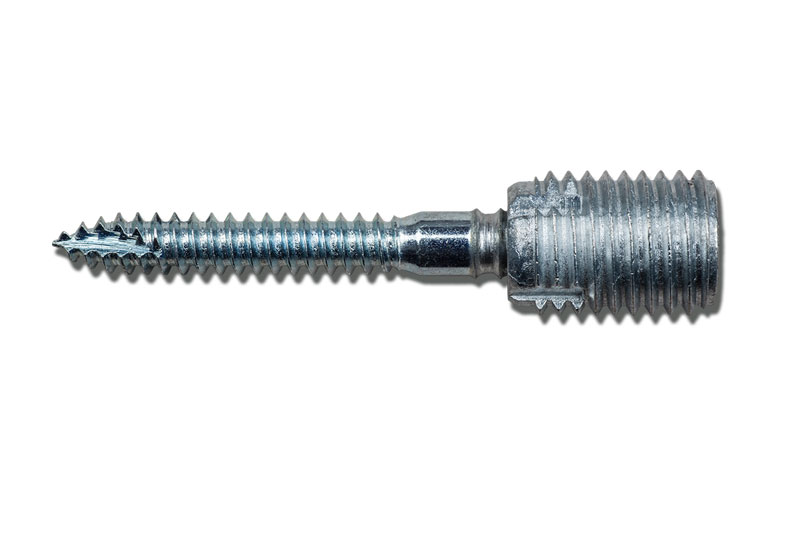

I have seen a hinge screw called Adjufix that looks like this:

How well do these work in hollow block/lightweight concrete? Are there any specific products to look for?

I am going to install a couple of interior doors in a basement with hollow block/lightweight concrete. Previously, I have used traditional longer hinge screws with matching plugs:

However, in all cases, I have had trouble getting them to hold firmly, so in some cases, I have had to drill additional anchor points, and in one case, I even had to use foam sealant.

Previous doors are mounted with nails in wooden pieces that have been inserted into the stone.

I have seen a hinge screw called Adjufix that looks like this:

How well do these work in hollow block/lightweight concrete? Are there any specific products to look for?

Two advantages of frame sleeves & loose screws are:

- it is easier to mark exactly where to drill in brick/concrete/cellular concrete/etc. Yes, there are special "center drill templates" to buy

- you can choose the "right" screw for the right material, wood/plug/lightweight concrete/etc.

There are special screws "only" for lightweight concrete/cinder blocks.

For frame sleeves, there are pressure distribution washers that are good to use during installation in, for example, lightweight concrete.

- it is easier to mark exactly where to drill in brick/concrete/cellular concrete/etc. Yes, there are special "center drill templates" to buy

- you can choose the "right" screw for the right material, wood/plug/lightweight concrete/etc.

There are special screws "only" for lightweight concrete/cinder blocks.

For frame sleeves, there are pressure distribution washers that are good to use during installation in, for example, lightweight concrete.

Sounds good, so it's the "centrum-bort-mall" and pressure distribution washers I need. Then it's important to find the right screw for the walls.

I've always used extra-long frame screws (even though it hasn't worked in this case), how should one think here? Should the sleeve be extra-long, or is it the screw? And do you use a plug for the screw as usual?

I've always used extra-long frame screws (even though it hasn't worked in this case), how should one think here? Should the sleeve be extra-long, or is it the screw? And do you use a plug for the screw as usual?

I have just installed 4 new interior doors in my basement made of lightweight concrete using Adjufix and suitable screws for lightweight concrete. Overall, I am absolutely satisfied! The lightweight concrete screw goes out approximately 70-100mm into the concrete.

I have never used the center template, didn't even know it existed until now when I was reading a bit on Essev's assembly instructions.

Whether the frame sleeve should be short/normal/long depends on how much distance there is between the frame & frame hole/wall.

If you use a plug, the screw should be a bit longer than the plug + the material that is fastened (which is a few mm), so the screw should be the plug's length plus about 1cm.

Whether the frame sleeve should be short/normal/long depends on how much distance there is between the frame & frame hole/wall.

If you use a plug, the screw should be a bit longer than the plug + the material that is fastened (which is a few mm), so the screw should be the plug's length plus about 1cm.

you can always cut the sleeves if they become too long.

Is it a hollow brick wall or a lightweight concrete wall you have? Hollow brick can be a bit tricky regardless of the fastening since there's sometimes just air to screw into....

A small casting can ease the work......but of course, it's a bit of extra fuss...

Is it a hollow brick wall or a lightweight concrete wall you have? Hollow brick can be a bit tricky regardless of the fastening since there's sometimes just air to screw into....

A small casting can ease the work......but of course, it's a bit of extra fuss...

I know there were concrete blocks in the garage and I believe it's the same in the rest of the basement, it's only referred to as lightweight concrete (and not blue concrete). But I have also experienced that when I drill, I reach cavities, which would indicate hollow blocks. The drill hammer cuts through the walls like butter regardless, the hard part is getting bolts and screws to really grip. It's important to choose the right plugs.

I have put up some heavy-duty shelves and even beams for a clothesline with strong bolts, but even here I felt that I didn’t quite get that resistance when screwing in the bolts as you do in concrete. So far, all my fittings have held. Almost all the fittings made by the previous owner have come loose, but they used substandard screws and plugs. I have generally oversized to be on the safe side.

But when I installed the two exterior doors, unfortunately, that wasn't enough, the stone behind cracked which meant that you could move the door frame in certain places. However, exterior doors were a bit more troublesome because there is a small cavity between the brick and concrete blocks where the stone you fasten to easily breaks in the middle. It probably would have been better to fill the gap first.

Another idea is otherwise to use the old trick of embedding wood into the wall, but then it's really important to know where the holes should be from the start, which is not easy for me as I don't work with this. Moreover, the wooden pieces should fit into the cavities precisely, with no room for movement.

I have put up some heavy-duty shelves and even beams for a clothesline with strong bolts, but even here I felt that I didn’t quite get that resistance when screwing in the bolts as you do in concrete. So far, all my fittings have held. Almost all the fittings made by the previous owner have come loose, but they used substandard screws and plugs. I have generally oversized to be on the safe side.

But when I installed the two exterior doors, unfortunately, that wasn't enough, the stone behind cracked which meant that you could move the door frame in certain places. However, exterior doors were a bit more troublesome because there is a small cavity between the brick and concrete blocks where the stone you fasten to easily breaks in the middle. It probably would have been better to fill the gap first.

Another idea is otherwise to use the old trick of embedding wood into the wall, but then it's really important to know where the holes should be from the start, which is not easy for me as I don't work with this. Moreover, the wooden pieces should fit into the cavities precisely, with no room for movement.

According to this "manual," wall plugs shouldn't even be necessary for screws in lecablock: https://www.essve.com/globalassets/...karm/10_montagesystem-indu-prog-karmhylsa.pdf

If it's hollow bricks, however, it’s a bit more complicated. Hmm, I might need to buy screws for both since I’m not entirely sure what I have here. Most indications point to lecablock, but at the same time, I know it usually drills unevenly with a hammer drill.

If it's hollow bricks, however, it’s a bit more complicated. Hmm, I might need to buy screws for both since I’m not entirely sure what I have here. Most indications point to lecablock, but at the same time, I know it usually drills unevenly with a hammer drill.

No plugs for the aerated concrete screw - it holds like hell anyway.

There are many tools and gadgets from essve, but the only thing you need is a hex socket that fits inside the sleeve, for installation and adjustment.

There are many tools and gadgets from essve, but the only thing you need is a hex socket that fits inside the sleeve, for installation and adjustment.

Click here to reply