3,446 views ·

11 replies

3k views

11 replies

Is thin-walled square tube enough for gym equipment

I'm planning to weld some gym equipment, like cable machines in various forms, lat pulldowns, etc. It feels unnecessary to simulate durability in a CAD program, so I'm asking you in the forum instead whether a precision square tube 40x40x1.5mm would suffice or if you would choose cold-formed construction tubes 50x50x3mm? The thinner one is easily accessible at Biltema, while the heavier one involves more costs with shipping and other factors. For bending, it's 430mm toward support and about 1500N force on 40x40mm and 1.5mm wall.

Ref: additional info

Ref: additional info

Last edited:

Member

· Västerbottens län

· 18 024 posts

How good are you at welding?

With 1.5 in material thickness, it's easy to burn holes.

Protte

With 1.5 in material thickness, it's easy to burn holes.

Protte

I've welded for 25 years (not certified), and I have my ESAB-mig calibrated for 1.5 and 2mm, so it usually turns out decently at least.prototypen said:

However, I will make sure to get as long weld seams as possible by using flat iron 6mm and then bolt the square tubes with these flat irons at the stress points.

It would have been easier to help if one had seen a simple sketch with approximate measurements. What weight/load does it need to support? The material of Biltema's profiles seems to be Q195 = S185

http://www.steelnumber.com/en/equivalent_steel_iron_eu.php?zname_id=2662

Not super good material, that is. Keep in mind that in addition to more difficult welding, the construction becomes more sensitive to damage ("poor" steel with thin walls) and, for example, subsequent buckling.

http://www.steelnumber.com/en/equivalent_steel_iron_eu.php?zname_id=2662

Not super good material, that is. Keep in mind that in addition to more difficult welding, the construction becomes more sensitive to damage ("poor" steel with thin walls) and, for example, subsequent buckling.

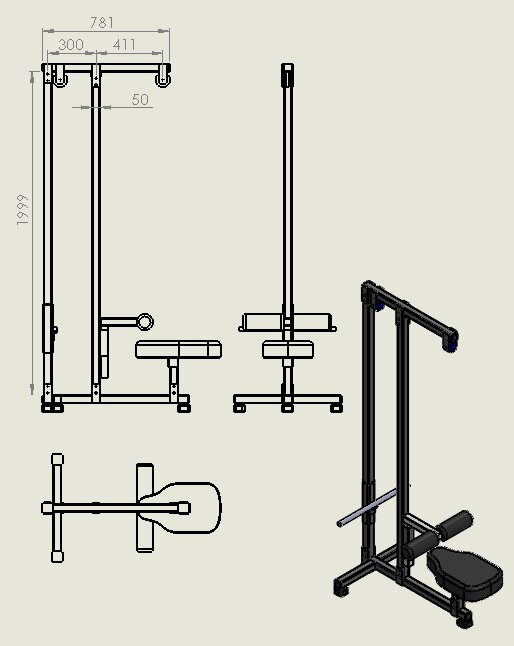

I can provide a sketch with measurements.R Razmataz said:Would have been easier to help if we had seen a simple sketch with approximate measurements. What is it supposed to support in terms of weight/load? The material of Biltema's profiles seems to be Q195 = S185

[link]

Not great material, in other words. Keep in mind that besides more difficult welding, the construction becomes more susceptible to damage ("poor" steel with thin walls) and, for example, subsequent buckling.

I also see online how line machines with similar constructions of thin-walled material have a maximum load of 80kg, which is insufficient. The construction should at least handle 120kg, so right there, thin-walled seems like a less smart choice. If there had been a square tube that fits with some clearance (about 1mm) in a KKR 50x50x3 (large corner radius), the choice would have been less difficult.

My experience is that it's easy to oversize more than needed. I have previously welded professionally, mainly MAG.

Beyond that, I probably can't contribute more.

Beyond that, I probably can't contribute more.

L L A Axelsson said:In my experience, it is easy to over-dimension more than necessary. I have previously welded professionally, mainly MAG.

More than that, I probably cannot

L L A Axelsson said:Johan- said:

I can produce a sketch with measurements.

I also see online how line machines with a similar construction of thin-walled material have a maximum load of 80kg, which is on the low side. The construction should at least handle 120kg, so already there, thin-walled seems like a less smart choice. If there had been a square tube that fits with a bit of play (about 1mm) in a KKR 50x50x3 (large corner radius), the choice would have been less difficult.L L A Axelsson said:

An over-dimensioning does come at a cost and since this is not something that will be sold with a guarantee on lifespan and also must handle some overload, over-dimensioning feels unnecessary. I plan to manufacture 5 or 7 line machines in total, so the extra cost in total feels even more unnecessary.L L A Axelsson said:

Is there a risk of personal injury if it doesn't hold? (I don't know anything about line machines).

Failure usually does not occur suddenly but starts with cracking, often near a weld.

Addition: If there is no risk of personal injury, it is possible to strengthen what might not hold afterwards.

Failure usually does not occur suddenly but starts with cracking, often near a weld.

Addition: If there is no risk of personal injury, it is possible to strengthen what might not hold afterwards.

Last edited:

L L A Axelsson said:

I'm just saying it's hard to say if the beam is okay if you don't know what the construction looks like or how it will (and can) be used. Is the ideal bending case you referred to really the worst the beams will be subjected to? It might be worth considering if there is a risk of personal injury.Johan- said:

Over-dimensioning does come at a cost, and since this isn't something that will be sold with a lifespan guarantee and also withstand certain overloads, over-dimensioning feels unnecessary. I've planned to manufacture 5 or 7 linmaskiner in total, so the extra cost on the whole seems even more unnecessary.

Here is a sketch of one of the machines that might be helpful.R Razmataz said:I just mean that it's difficult to say if the beam is okay if you don't know what the construction looks like or how it should (and can) be used. Is the ideal bending case you referenced definitely the worst the beams will be subjected to? It might be worth considering if there's a risk of personal injury.

If someone yanks down the lat bar instead of pulling gently, the load could temporarily become higher than the static 120kg. What could happen if the breaking strength of the cable or a weld is exceeded is that you could pull the lat bar down onto the back of your neck or on your Adam's apple with a corresponding force of 120+ kg.

(Editor: spelling mistake + addition)

Last edited:

A weld that is properly executed does not break, however, the base material adjacent to the weld can start to crack under overload. The vehicle inspection applies the method where the static load of, for example, a vehicle frame must be no more than one-third of the material's strength to allow margin for the dynamic forces that are difficult to calculate, as an example.

As I understand it, there is a risk of personal injury if the pipes are overloaded more than they can withstand, and therefore the frame probably needs to be strength-calculated, which costs a bit. An alternative is to over-dimension, but that requires some experience.

As I understand it, there is a risk of personal injury if the pipes are overloaded more than they can withstand, and therefore the frame probably needs to be strength-calculated, which costs a bit. An alternative is to over-dimension, but that requires some experience.

Best answer

I just took a quick look at deflection. And it seems quite negligible with the loads you mention. It might feel a bit flexible around the two 1999mm pipes. But if so, you can certainly reinforce afterward with a support on each side. It doesn't immediately seem completely bad with the Biltema beam.

Edit:

With a moment of 120*9.82*0.46=~=550Nm, you get a bending stress of 193 MPa..... which is a bit over the material's limit 😇 I might have to recommend using double beams if you're going with Biltema 40x40x1.5. Alternatively, see if they have a thicker one. A 40x60x1.5 would, however, bring you down to 110MPa.

http://www.steelnumber.com/en/steel_composition_eu.php?name_id=419

https://www.omnicalculator.com/construction/bending-stress

Edit:

With a moment of 120*9.82*0.46=~=550Nm, you get a bending stress of 193 MPa..... which is a bit over the material's limit 😇 I might have to recommend using double beams if you're going with Biltema 40x40x1.5. Alternatively, see if they have a thicker one. A 40x60x1.5 would, however, bring you down to 110MPa.

http://www.steelnumber.com/en/steel_composition_eu.php?name_id=419

https://www.omnicalculator.com/construction/bending-stress

Last edited:

Click here to reply

Similar threads

-

Råd: räcker easy cover select på detta?

Färg, Måla & Tapetsera -

Plankgolv parallellt med bjälkar - räcker det med kortlingar?

Golv -

Caparol reklam?? Räcker väl oftast med två strykn vid ommålning

Färg, Måla & Tapetsera -

Räcker en kniv för att lossa färg, tak nock i bågeform.:

Färg, Måla & Tapetsera -

Rostskydda fyrkantsrör invändigt?

Metall - stålkonstruktioner, svets och smide