11,724 views ·

21 replies

12k views

21 replies

Drilling holes in a leca wall

Hello

I'm going to make a hole for a flue pipe through a lecablock wall (25cm thick interior wall).

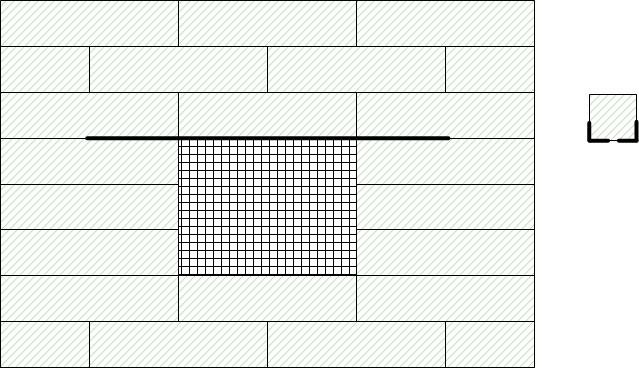

The hole will be at the end of the wall towards the exterior wall.

I don't think the wall is integrated into the exterior wall.

The floor joists are above the lecablock wall.

The hole will be about 170cm high and approximately 40cm wide and high.

Not a heavy load directly at the corner, but I'm wondering if I'm doing something foolish now?

I'm going to make a hole for a flue pipe through a lecablock wall (25cm thick interior wall).

The hole will be at the end of the wall towards the exterior wall.

I don't think the wall is integrated into the exterior wall.

The floor joists are above the lecablock wall.

The hole will be about 170cm high and approximately 40cm wide and high.

Not a heavy load directly at the corner, but I'm wondering if I'm doing something foolish now?

How much Leca will you have left between the hole and the top of the wall?

Will there be a floor joist directly above the hole?

If the answer is yes to the latter, and there are less than 3 layers of Leca blocks remaining, I would consider supporting the roof in the hole with iron. For example, two angle profiles of 100*100 that are around 1200 long (400mm outside the hole) and which are mounted flush in the rest of the wall.

Note, completely without the knowledge to calculate this and solely using common sense to oversize when I'm unsure about the construction solution.

Will there be a floor joist directly above the hole?

If the answer is yes to the latter, and there are less than 3 layers of Leca blocks remaining, I would consider supporting the roof in the hole with iron. For example, two angle profiles of 100*100 that are around 1200 long (400mm outside the hole) and which are mounted flush in the rest of the wall.

Note, completely without the knowledge to calculate this and solely using common sense to oversize when I'm unsure about the construction solution.

The hole will be 1500mm to 1750mmcorre said:How much leca will you have left between the hole and the top of the wall?

Will there be a floor joist right above the hole?

If the answer is yes to the latter, and there are less than 3 layers of lecablock left, then I would look at reinforcing the roof in the hole with iron. For example, two angle profiles at 100*100 that are around 1200 long (400mm outside the hole) and that are mounted flush with the rest of the wall.

Note, completely without knowledge of calculating this and solely with the common sense of over-dimensioning when I am unsure about the construction solution.

Total height will be 2400, a leca is about 19cm high, so about 3 stones left.

I will check how the joists are situated but there are beams on the wall anyway. Maybe not directly over the hole.

My construction brain doesn't keep up with the reinforcement; should the irons go around the outside of the hole or be embedded on top?

Thanks for the response, by the way

What kind of exterior wall do you have? Or do you mean the hole will be just before the angle towards the other exterior wall?

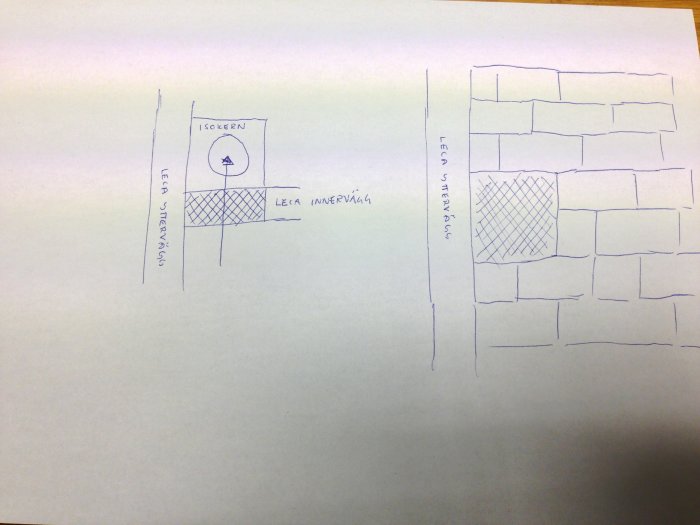

Maybe draw where the hole will be in relation to the walls.

I assumed a hole in the middle of a wall in my example.

If it's a corner, I would do the same but drill an L-angle with a 10mm drill bit towards the inside of the side wall, so that the inside's angle iron can go through that wall and get support in the same way.

Maybe draw where the hole will be in relation to the walls.

I assumed a hole in the middle of a wall in my example.

If it's a corner, I would do the same but drill an L-angle with a 10mm drill bit towards the inside of the side wall, so that the inside's angle iron can go through that wall and get support in the same way.

It's leca, also 25cm which the hole will be open towards.corre said:What kind of exterior wall do you have? Or do you mean that the hole will come just before the angle towards the other exterior wall?

Maybe draw where the hole will be in relation to the walls.

I assumed a hole in the middle of a wall in my example.

If it's a corner, I would have done the same but drilled an L-angle with a 10mm drill towards the inside of the sidewall so that the inner angle iron can go through that wall and get support in the same way.

The chimney is on the backside of the hole so I can only access from one side.

Ah!

With leca in the wall, you can easily go through an angle iron after drilling a couple of holes in the outer wall.

I think you could drill with a 25mm concrete drill, 1m long straight into the overlying block and cast two 20mm rebar in the hole.

Given the placement, there shouldn't be much weight to distribute above the hole from the floor joists.

With leca in the wall, you can easily go through an angle iron after drilling a couple of holes in the outer wall.

I think you could drill with a 25mm concrete drill, 1m long straight into the overlying block and cast two 20mm rebar in the hole.

Given the placement, there shouldn't be much weight to distribute above the hole from the floor joists.

So, I should pre-drill holes in the outer wall and then insert angle irons that go almost through the outer wall and then rest on the opposite side of the inner wall?corre said:Ah!

With leca in the wall, you can easily break through an angle iron after drilling a couple of holes in the outer wall.

I think you could drill with a 25mm concrete drill, 1m long straight into the block above and cast two rebar, 20mm, into the hole.

Due to the placement, it should not be a large weight that needs to be distributed above the hole from the floor joists.

And the reinforcement should be from the ceiling in the hole and straight up?

No, there's nothing directly above that adds weight to that floor joist.

There is a stove nearby on the upper side, but it adds weight outside the hole (stands about 30 cm in front of the chimney)

And it doesn't press directly down into the hole but about first 30 cm and forward on the wall.

I meant that the rebar could replace the angle irons since it's against an outer wall and with low (probably) load. However, I would prefer not to recommend it. It's difficult to drill straight into the wall and get the holes right.D09 said:So I should pre-drill holes in the outer wall and then insert angle irons that go almost through the outer wall and then rest on the opposite side of the inner wall?

And the reinforcement should be from the ceiling in the hole and straight up?

No, there's nothing directly above that burdens the floor structure.

There is, however, a fireplace nearby on the upper side but it burdens outside the hole (it stands about 30 cm in front of the chimney) and doesn't press directly downward against the hole but about the first 30 cm and forward on the wall

The solution with angle irons is probably preferable, but a bit more cumbersome to get in place due to the outer wall's angle.

Drill into the outer wall with a 10mm drill, insert the angle irons, and get a support in the outer wall that is as deep as the wall.

By the way, is the chimney going to run horizontally through another room before going out? The chimney sweep is OK with that?

Yep, the chimney sweep inspected it in connection with the installation of the stove.corre said:I meant the rebar could replace the angle irons since it's against an outer wall and with low (probably) load. However, I want to avoid recommending it. It's difficult to drill straight into the wall and get the holes right.

The solution with angle irons is probably preferable, but a bit more complicated to get in place due to the outer wall at an angle.

Drill into the outer wall with a 10mm drill, hammer in the angle irons, and get a support in the outer wall that is as deep as the wall.

By the way, does the chimney go horizontally through another room before it goes out? The chimney sweep is okay with that?

Aha, you meant to drill and reinforce from outside?

Should the irons be hammered in before demolition?

Once again, you're awesome

Yes, insert them 1m through both the outer wall and the inner wall.D09 said:

Mainly to prevent the bottom row from collapsing. But I believe more in the angle iron solution myself.

Yes, you should install them beforehand, or put a prop on the floor so it doesn't sink when you demolish.D09 said:

[/QUOTE]D09 said:

Thanks

What do you think about using the same principle but with a horizontal recessed H-beam that is about 17cm wide, resting about 15cm on the outer wall and 20cm on the inner wall?

I'm stuck because I can't access the backside due to the chimney and tiled wall.

Then you could cut out about 18 cm, save about 7 to keep the stone in place, insert the beam, and then make the hole below?

I'm stuck because I can't access the backside due to the chimney and tiled wall.

Then you could cut out about 18 cm, save about 7 to keep the stone in place, insert the beam, and then make the hole below?

Well, I'm a bit against breaking apart the leca. It's quite sensitive to compressive loads as it is. And it's quite difficult to get the beam counter-tensioned and without making a huge hole.

Do you already have the beam? Otherwise, I think the angle iron solution is easier to work with.

You can cut the grooves with the angle grinder, drill a couple of holes, and then drive the angle iron in from inside the room. That way, you never have to approach this from the other side.

Alt3, you use a flat iron on the wall you can't reach, screwed with light concrete screws into the transverse wall.

In this, you weld the angle irons, so you avoid risking breaking something on the tiles on the other side.

It then becomes like a post iron.

Like this, but much larger and with angle iron.

http://biltema.se/sv/Bygg/Monteringsdetaljer/Stolp--och-balksko/Stolpsko-TT-87882/

alt4

Weld a frame in angle iron, like a picture frame. Then you groove the leca on each side and mount this frame into the hole and screw it with light concrete screws.

After that, it's just a matter of chipping the iron

Important is the height of the angle iron, at least 80mm high on the horizontal side, as it's the one that will bear the load.

Do you already have the beam? Otherwise, I think the angle iron solution is easier to work with.

You can cut the grooves with the angle grinder, drill a couple of holes, and then drive the angle iron in from inside the room. That way, you never have to approach this from the other side.

Alt3, you use a flat iron on the wall you can't reach, screwed with light concrete screws into the transverse wall.

In this, you weld the angle irons, so you avoid risking breaking something on the tiles on the other side.

It then becomes like a post iron.

Like this, but much larger and with angle iron.

http://biltema.se/sv/Bygg/Monteringsdetaljer/Stolp--och-balksko/Stolpsko-TT-87882/

alt4

Weld a frame in angle iron, like a picture frame. Then you groove the leca on each side and mount this frame into the hole and screw it with light concrete screws.

After that, it's just a matter of chipping the iron

Important is the height of the angle iron, at least 80mm high on the horizontal side, as it's the one that will bear the load.