5,014 views ·

31 replies

5k views

31 replies

Is it possible to fill large hole in brick after wall plugs have crumbled?

Hello all builders!

I had a roller blind installed with plugs where the material is some form of red porous red brick (apartment building from the early 1900s in central Stockholm). The plugs and everything came loose, leaving holes after the plugs, which were considerably larger.

I went up in size and tried to drill in larger plugs, but the brick is so porous that it just became one big hole where previously the two plugs were.

I'm wondering if anyone knows if it would be suitable to fill the entire hole with some compound and then press in the plugs and wait for it to dry, and if so, what material I should inject. Attaching a picture.

I had a roller blind installed with plugs where the material is some form of red porous red brick (apartment building from the early 1900s in central Stockholm). The plugs and everything came loose, leaving holes after the plugs, which were considerably larger.

I went up in size and tried to drill in larger plugs, but the brick is so porous that it just became one big hole where previously the two plugs were.

I'm wondering if anyone knows if it would be suitable to fill the entire hole with some compound and then press in the plugs and wait for it to dry, and if so, what material I should inject. Attaching a picture.

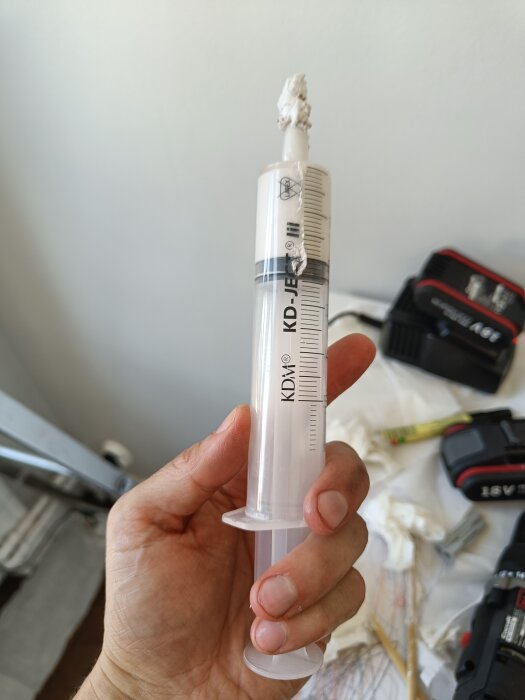

Update. Bought some type of filler at Clas Ohlson after a tip from the staff there. Put it in a wound syringe and filled the hole with the filler before pressing in the plugs. I'm going to let it dry for a while before I try to put up the roller blind, and then I'll see if it works. Attaching pictures.

That won't hold a curtain rod unless it's Nils Karlsson Pyssling you live with.

Isn't it a plasterboard you have? Are you sure it's brick you're drilling into? It would be plastered brick in that case.

It looks like it's open behind the surface so to speak.

I would have taken a 70mm hole saw and drilled a disc so you can inspect what you have back there to begin with....

Isn't it a plasterboard you have? Are you sure it's brick you're drilling into? It would be plastered brick in that case.

It looks like it's open behind the surface so to speak.

I would have taken a 70mm hole saw and drilled a disc so you can inspect what you have back there to begin with....

Filler is not the right product because it shrinks and is weak. It can also only be used up to 3 mm thickness. But Clas Ohlson has a very good product for this purpose which is a quick-cement:

https://www.clasohlson.com/se/Quick...g7to9J-0WE3relvW4XGPbWTEvqBXNa8waAj3AEALw_wcB

You have to work really quickly once you've mixed the cement paste because it really sets fast. It has saved my botched drillings in concrete when I've hit a stone and the hole has become too large.

https://www.clasohlson.com/se/Quick...g7to9J-0WE3relvW4XGPbWTEvqBXNa8waAj3AEALw_wcB

You have to work really quickly once you've mixed the cement paste because it really sets fast. It has saved my botched drillings in concrete when I've hit a stone and the hole has become too large.

That's probably safest. Vacuum the holes thoroughly before you smear in the cement.K Kaskelot said:

That will hold just fine, I've been doing it myself since time immemorial when the drilling goes wrong. Just make sure it's completely dry, it looks like a big hole so preferably a week's drying time, otherwise you'll pull out the plug when you screw in the screw.

The filler cracks when he drives the screw into the plugnamnbyte said:

Trust me.

No, not if it’s thoroughly dry and well-filled, I've done so myself with both some curtains and the home theater speakers. If it's not dry all the way through, you'll pull out the plug.Farstatjej90 said:

It's a vertical tensile force against a horizontal mounting, also presumably with a support underneath in the form of an L. It will hold, I have 5kg speakers mounted that way. However, with sturdy screws/plugs.

Really fun to get such a response. I'll try to wait at least a week and then see if I can get the screw out and make it stay. If the roller blind comes loose, it doesn't matter too much.

It may well be that even a technically inferior method can work with a bit of luck. I'll provide an update in the future.

It may well be that even a technically inferior method can work with a bit of luck. I'll provide an update in the future.

Why on earth would you use the wrong material? I've tried to do this myself, and the filler cracked. It's great that your speakers are hanging up, but there are much better materials to use. Do that...namnbyte said:

No, not if it's thoroughly dry and well-filled, I've done so myself with both some curtains and home theater speakers. If it's not dry all the way through, you'll pull out the plug.

It is a vertical tensile force against a horizontal attachment, moreover with an assumed support underneath in the form of an L. It will hold, I have 5kg speakers that have been mounted in that way. However, with sturdy screws/plugs.

No need to go overboard, you can stop screwing in even before that. The wall doesn't move significantly, there's no point in tightening so much. It's not the screw's tension against the plug that's the weak link in such mounting.Farstatjej90 said:

But yes, he could also mill out a groove in the brick and cast in an H-beam, which the curtain bracket is then welded to. Then it will hold even for your use of curtains!

EDIT: But to be really sure, he should probably also drill into the H-beam from the outside and attach wires to it to also utilize concrete foundations buried outside. This way, you can tighten the wire as desired or if there's an overload on the curtain bracket during, e.g., a visit.