28,599 views ·

33 replies

29k views

33 replies

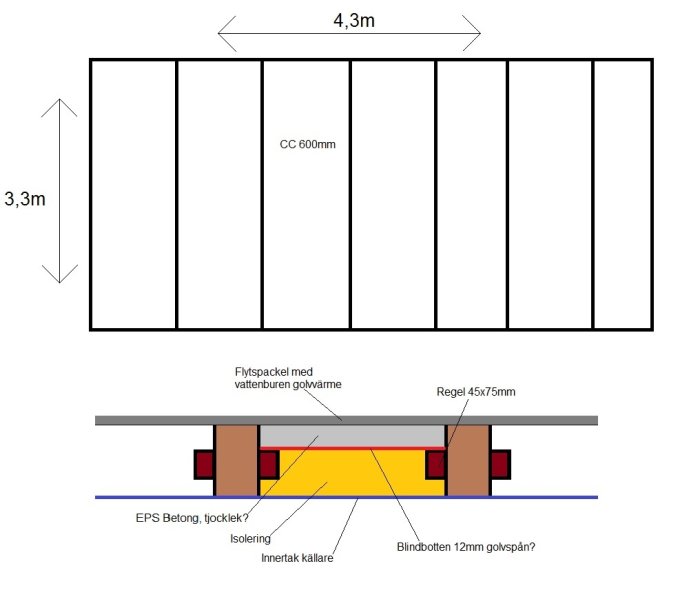

EPS Concrete on wooden joists, thickness?

Hello!

I am planning to fill the wooden framework in the hallway with EPS concrete, then lay 17mm underfloor heating and self-leveling compound over it.

The question is, as I don't want to use more than necessary (purely for economic reasons), how thin a layer can I have while still maintaining load-bearing capacity?

Then the question is whether 12mm, 18mm, or 22mm chipboard can be used as a subfloor (is 12mm sufficient)?

I am planning to fill the wooden framework in the hallway with EPS concrete, then lay 17mm underfloor heating and self-leveling compound over it.

The question is, as I don't want to use more than necessary (purely for economic reasons), how thin a layer can I have while still maintaining load-bearing capacity?

Then the question is whether 12mm, 18mm, or 22mm chipboard can be used as a subfloor (is 12mm sufficient)?

What is supposed to be thin? The leveling compound or the EPS?

If it's an economic issue, I would skip the EPS entirely and lay down grooved floor particle boards instead. If you have more time than money, you can mill the grooves yourself in regular particle board. Coverage over the loops is determined by loop dimension and what you plan to lay on top, as well as your tolerance for a "striped" floor.

If it's an economic issue, I would skip the EPS entirely and lay down grooved floor particle boards instead. If you have more time than money, you can mill the grooves yourself in regular particle board. Coverage over the loops is determined by loop dimension and what you plan to lay on top, as well as your tolerance for a "striped" floor.

What is the point of EPS? Why not just screw-glued chipboard flooring that you float on? If you want to keep the height down, you can recess the chipboard between the joists. Since it is not a wet room, it is not crucial for it to be completely rigid. What type of surface covering will you use?

It becomes very heavy. With 5 cm EPS concrete and 2 cm self-leveling compound, the self-weight is around 1.2 kN/sqm. 45x220 beams are on the flimsy side.

True... there shouldn't be any difference xD

I'll probably go with this, frame cc 300mm between the studs (is 45x70 enough?) and lay down grooved particle boards. Then I'll rout the studs (so the underfloor heating pipe goes down). Lay down underfloor heating plate (if needed?), then reinforcement mesh and then leveling compound (how many mm should it be over the board/pipe when it's not a wet room?)

Thank you so much for your help!

I'll probably go with this, frame cc 300mm between the studs (is 45x70 enough?) and lay down grooved particle boards. Then I'll rout the studs (so the underfloor heating pipe goes down). Lay down underfloor heating plate (if needed?), then reinforcement mesh and then leveling compound (how many mm should it be over the board/pipe when it's not a wet room?)

Thank you so much for your help!

Very heavy?

I don't have the dry weight of EPS in my head, but a bag weighs 17kg and is enough for 5cm over one square meter. Then you add water, but some of it evaporates. Normally, screed is 17kg/sqm/cm, so the dry weight becomes around 50kg/sqm for a total of 7cm, BUT then you have a composite construction.

I believe the construction for EPS in beams is about 17cm of EPS and at least 20mm of screed. Then you should have at least 20mm of screed over the pipe crown or the same coverage as the pipe diameter anyway.

When you lay a chipboard floor between the beams, the stiffening properties of the chipboard disappear, so no supplier would recommend doing this unless, for example, you cast with self-supporting ROT-bruk. But then it's maybe 40mm over the pipe and probably over the floor joists.

But many have done what you’re thinking and made it work.

I don't have the dry weight of EPS in my head, but a bag weighs 17kg and is enough for 5cm over one square meter. Then you add water, but some of it evaporates. Normally, screed is 17kg/sqm/cm, so the dry weight becomes around 50kg/sqm for a total of 7cm, BUT then you have a composite construction.

I believe the construction for EPS in beams is about 17cm of EPS and at least 20mm of screed. Then you should have at least 20mm of screed over the pipe crown or the same coverage as the pipe diameter anyway.

When you lay a chipboard floor between the beams, the stiffening properties of the chipboard disappear, so no supplier would recommend doing this unless, for example, you cast with self-supporting ROT-bruk. But then it's maybe 40mm over the pipe and probably over the floor joists.

But many have done what you’re thinking and made it work.