4,120 views ·

11 replies

4k views

11 replies

Choice of split-level construction?

We are preparing for the construction of our upcoming split-level villa. I have talked to a potential contractor about the choice of construction technique for the split-level floor (basement floor) and he had three different proposals on how to do this.

1. "Frigolitlego" type dorocell

2. Isoblock type insulated lecablock

3. Lecablock, classic masonry leca with 50mm foam plastic on the inside followed by installation space and boards.

The conditions are that one long side of about 10m (with 2 support walls inside the house) will be backfilled to a height of about 2m and the foundation is built with edge elements.

Of course, he had his views on the different choices and after searching a bit online myself, I haven't been able to find any decisive points in favor of any method.

I have, of course, also consulted the designer on the matter, and he has no opinions from a strength perspective.

With the information I have now, it feels like the best solution is to choose the construction that the contractor is "comfortable" and experienced with.

As the owner, there are economic and energy considerations to the different choices, both short- and long-term...

The question is, what are the decisive points?

Why would you choose to build with a particular method?

1. "Frigolitlego" type dorocell

2. Isoblock type insulated lecablock

3. Lecablock, classic masonry leca with 50mm foam plastic on the inside followed by installation space and boards.

The conditions are that one long side of about 10m (with 2 support walls inside the house) will be backfilled to a height of about 2m and the foundation is built with edge elements.

Of course, he had his views on the different choices and after searching a bit online myself, I haven't been able to find any decisive points in favor of any method.

I have, of course, also consulted the designer on the matter, and he has no opinions from a strength perspective.

With the information I have now, it feels like the best solution is to choose the construction that the contractor is "comfortable" and experienced with.

As the owner, there are economic and energy considerations to the different choices, both short- and long-term...

The question is, what are the decisive points?

Why would you choose to build with a particular method?

Anyone have an opinion or experience with the different materials for building a basement or cellar?

I've been wondering if it's really correct to build the following construction considering moisture migration?

-Isodrän equivalent

-Leca bricks

-50mm foam insulation

-steel studs with installation space

-boards like OSB or plywood and gypsum

I've been wondering if it's really correct to build the following construction considering moisture migration?

-Isodrän equivalent

-Leca bricks

-50mm foam insulation

-steel studs with installation space

-boards like OSB or plywood and gypsum

We are in the same situation and are far from being gurus in the field. But after reading a bit about the cellular plastic option, it seems that fire safety is alarmingly low. Both the Swedish Fire Protection Association and other knowledgeable organizations suggest that construction with cellular plastic should be limited. Maybe there is some fire-technical solution to still be able to use cellular plastic.

Thanks for that, I hadn't actually considered fire in this aspect...pjop said:We are in the same situation and are far from gurus in the field. But after reading a bit about the foam plastic alternative, it seems that the fire safety is alarmingly low. Both the fire protection association and other knowledgeable organizations suggest that construction with foam plastic should be limited.

Maybe there is some fire technical solution to still be able to use foam plastic.

I vote that underground you should use thick regular leca with isodrän/pordrän on the outside (no iso on the inside, especially not underground).

Thanks for the opinions and viewpoints.

Underground, it will have Leca with pordrän (equivalent) on the outside.

However, it is not yet clear how it will be with all the freestanding masonry walls (which will be the majority). Leca is likely since there will only be a material construction in the basement floor. Then a wood facade will be added on the outside (a matter of taste but that's how it is), but the goal is to lower the U-value, so some form of insulation will likely be needed between Leca and the wood facade. The alternative is to build all freestanding walls with isoblock and then attach the wood facade, but there might be some cost difference between the two alternatives.

I will discuss this with the builder and see what his views are...

Underground, it will have Leca with pordrän (equivalent) on the outside.

However, it is not yet clear how it will be with all the freestanding masonry walls (which will be the majority). Leca is likely since there will only be a material construction in the basement floor. Then a wood facade will be added on the outside (a matter of taste but that's how it is), but the goal is to lower the U-value, so some form of insulation will likely be needed between Leca and the wood facade. The alternative is to build all freestanding walls with isoblock and then attach the wood facade, but there might be some cost difference between the two alternatives.

I will discuss this with the builder and see what his views are...

Are you going to have a stone house with a wooden house on the outside?

Everything takes a turn...

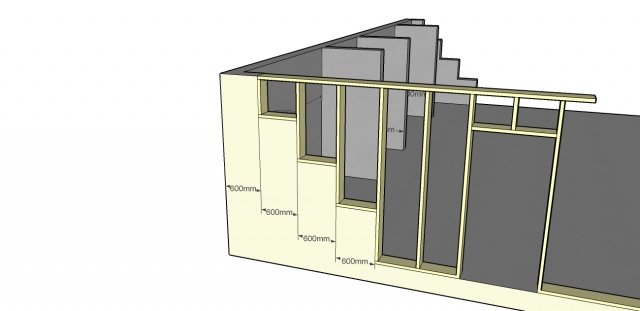

Had new conversations with the designer and builder and now it will NOT be a wooden house on a stone house, but only partially since it is in fact a split-level build.

Now it's leaning towards having a lecamur that can be backfilled. This will be clad with pordrän and conventional drainage. The wall will gradually transition to a wooden frame.

This will be a considerably cheaper construction in terms of insulation capability. Additionally, it is easier to work with a wooden construction throughout the house than mixing different types. Perhaps this is what "synpunkter" referred to with their question above...?

We'll see if this is the final solution...

Had new conversations with the designer and builder and now it will NOT be a wooden house on a stone house, but only partially since it is in fact a split-level build.

Now it's leaning towards having a lecamur that can be backfilled. This will be clad with pordrän and conventional drainage. The wall will gradually transition to a wooden frame.

This will be a considerably cheaper construction in terms of insulation capability. Additionally, it is easier to work with a wooden construction throughout the house than mixing different types. Perhaps this is what "synpunkter" referred to with their question above...?

We'll see if this is the final solution...

Last edited:

Yes, it is difficult to give recommendations on what exactly you should do.

We have "built" with Dorocell's lego blocks below ground and in a section where we won't have backfill.

The advantage, as we saw it, was that we could decide a little later in the project exactly how our plot would look. We made two retaining walls on the outside of the house wall so that we would have a straight edge at the joint between the backfilled and open part of the wall.

For the garage, we built with leca. It becomes very troublesome with the solution on the backfill and where we are going to have paneling on the wood frame.

It's hard to explain how it looks, but maybe you understand anyway.

What is convenient with the lego blocks is that it is relatively easy to fasten against them.

The downside is that there is a lot of work with reinforcement and then the casting.

It is definitely an advantage that the space becomes well insulated.

The leca blocks are heavy to handle. There's also a bit of fiddling with the mortar. I find it more difficult to attach frameworks.

On the other hand, it is very easy to plan and even improvise if you want to make changes.

A bit disjointed perhaps. But it is out of goodwill that I try to give my opinions.

I agree that it is probably smart to choose a variant that your builder is good at.

Good luck with your choice.

Best regards,

Anders.

We have "built" with Dorocell's lego blocks below ground and in a section where we won't have backfill.

The advantage, as we saw it, was that we could decide a little later in the project exactly how our plot would look. We made two retaining walls on the outside of the house wall so that we would have a straight edge at the joint between the backfilled and open part of the wall.

For the garage, we built with leca. It becomes very troublesome with the solution on the backfill and where we are going to have paneling on the wood frame.

It's hard to explain how it looks, but maybe you understand anyway.

What is convenient with the lego blocks is that it is relatively easy to fasten against them.

The downside is that there is a lot of work with reinforcement and then the casting.

It is definitely an advantage that the space becomes well insulated.

The leca blocks are heavy to handle. There's also a bit of fiddling with the mortar. I find it more difficult to attach frameworks.

On the other hand, it is very easy to plan and even improvise if you want to make changes.

A bit disjointed perhaps. But it is out of goodwill that I try to give my opinions.

I agree that it is probably smart to choose a variant that your builder is good at.

Good luck with your choice.

Best regards,

Anders.

Click here to reply

Similar threads

-

Nyasfalterad uppfart, men tveksam kring kvalitén

Grund & Markarbeten -

Grundolja - kvalitetsskillnader

Färg, Måla & Tapetsera -

Jahapp då var man utan el såhär på fredagskvällen 😥

El -

Nivålarm till sluten tank (avlopp)

Vatten & Avlopp -

Vilken bergvärmepump ska jag välja? Nibe, CTC, Bosch eller Thermia

Värmepumpar